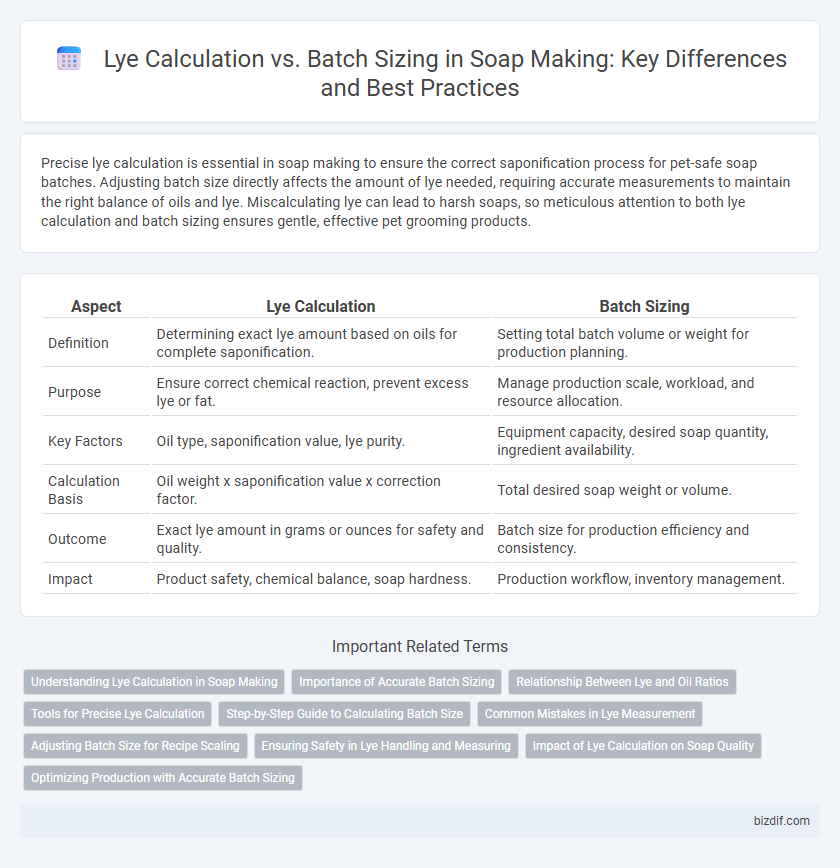

Precise lye calculation is essential in soap making to ensure the correct saponification process for pet-safe soap batches. Adjusting batch size directly affects the amount of lye needed, requiring accurate measurements to maintain the right balance of oils and lye. Miscalculating lye can lead to harsh soaps, so meticulous attention to both lye calculation and batch sizing ensures gentle, effective pet grooming products.

Table of Comparison

| Aspect | Lye Calculation | Batch Sizing |

|---|---|---|

| Definition | Determining exact lye amount based on oils for complete saponification. | Setting total batch volume or weight for production planning. |

| Purpose | Ensure correct chemical reaction, prevent excess lye or fat. | Manage production scale, workload, and resource allocation. |

| Key Factors | Oil type, saponification value, lye purity. | Equipment capacity, desired soap quantity, ingredient availability. |

| Calculation Basis | Oil weight x saponification value x correction factor. | Total desired soap weight or volume. |

| Outcome | Exact lye amount in grams or ounces for safety and quality. | Batch size for production efficiency and consistency. |

| Impact | Product safety, chemical balance, soap hardness. | Production workflow, inventory management. |

Understanding Lye Calculation in Soap Making

Accurate lye calculation is crucial for soap making, ensuring the precise amount of sodium hydroxide needed to saponify oils without leaving excess alkali or unreacted oils. This calculation depends on the specific oils used and their individual saponification values, which dictate how much lye each oil requires to transform into soap. Proper lye measurement directly influences the quality, safety, and curing time of the final soap batch, making it essential to adjust based on batch size for consistent results.

Importance of Accurate Batch Sizing

Accurate batch sizing is crucial in soap making to ensure the lye calculation aligns precisely with the oils and fats used, preventing issues like incomplete saponification or harsh soap. Properly sized batches enable consistent chemical reactions, maintaining the desired pH balance and ensuring product safety and quality. Mismatched batch sizes can lead to excess lye or unreacted oils, resulting in skin irritation or reduced soap longevity.

Relationship Between Lye and Oil Ratios

Accurate lye calculation is essential to ensure the correct saponification of oils in soap making, as the lye-to-oil ratio directly affects the soap's texture, hardness, and cleansing properties. Batch sizing impacts the precision of lye measurement, with larger batches requiring careful adjustment of lye amounts to maintain consistent oil ratios and prevent excess lye or oil. Understanding the relationship between lye and oil ratios allows soap makers to create balanced formulations that optimize curing time and produce safe, high-quality soap.

Tools for Precise Lye Calculation

Accurate lye calculation is essential in soap making to ensure proper saponification and avoid unbalanced batches. Tools such as lye calculators, soap-making software, and mobile apps use precise formulas to determine the exact amount of sodium hydroxide or potassium hydroxide needed based on oil types and batch size. These digital resources minimize errors and optimize batch formulation, enhancing soap quality and safety.

Step-by-Step Guide to Calculating Batch Size

Accurate lye calculation is essential for safe and effective soap making, ensuring the correct amount of sodium hydroxide neutralizes oils without excess causticity. Begin by determining the total oil weight, then use saponification values specific to each oil to calculate the precise lye quantity needed. Adjust batch size accordingly by scaling oil and lye amounts proportionally, maintaining safety margins and consistent soap quality.

Common Mistakes in Lye Measurement

In soap making, incorrect lye calculation often leads to dangerous batch inconsistencies, including overly caustic or under-cured soap. Common mistakes include misreading lye concentration, failing to adjust for batch size variations, and neglecting the water-to-lye ratio, which can alter saponification. Precise lye measurement using digital scales and recalculated ratios ensures batch accuracy and safe, consistent soap quality.

Adjusting Batch Size for Recipe Scaling

Accurate lye calculation is essential when adjusting batch size for soap making to maintain proper saponification and ensure product safety. Scaling a soap recipe requires proportionally recalculating lye and water amounts based on the new batch weight to preserve the chemical balance. Using a reliable lye calculator with precise batch sizing inputs prevents errors in alkali concentration, which can affect soap texture, hardness, and skin compatibility.

Ensuring Safety in Lye Handling and Measuring

Accurate lye calculation and precise batch sizing are critical to ensure safety in soap making by preventing excess caustic soda that can cause chemical burns or improper saponification. Measuring lye requires using digital scales for exact weight, avoiding volume estimation due to varying densities and environmental factors. Proper personal protective equipment (PPE) such as gloves and goggles must be worn during handling to minimize risk and maintain control over the chemical reaction.

Impact of Lye Calculation on Soap Quality

Accurate lye calculation directly influences soap quality by ensuring proper saponification, preventing excess causticity or oiliness in the final product. Precise batch sizing coupled with exact lye measurement maintains consistency across soap batches, enhancing texture and longevity. Errors in lye amount can lead to incomplete chemical reactions, resulting in lower-quality soap with poor skin compatibility and reduced shelf life.

Optimizing Production with Accurate Batch Sizing

Accurate lye calculation is essential for optimizing soap production efficiency by ensuring the correct chemical balance in each batch. Precise batch sizing directly influences the quality and consistency of the final soap, minimizing waste and reducing costs. Implementing advanced lye calculation tools and adjusting batch sizes based on raw material properties enhances overall production scalability and product reliability.

Lye Calculation vs Batch Sizing Infographic

bizdif.com

bizdif.com