Rebatching soap involves melting and reshaping pre-made soap bars, allowing pet owners to customize scents and ingredients without starting from raw materials. From-scratch soap making requires combining raw oils and lye, giving full control over formulas but demanding precise measurements and curing time. For pet-safe soap, from-scratch offers greater control over allergens, while rebatching is easier for beginners adapting existing soap recipes.

Table of Comparison

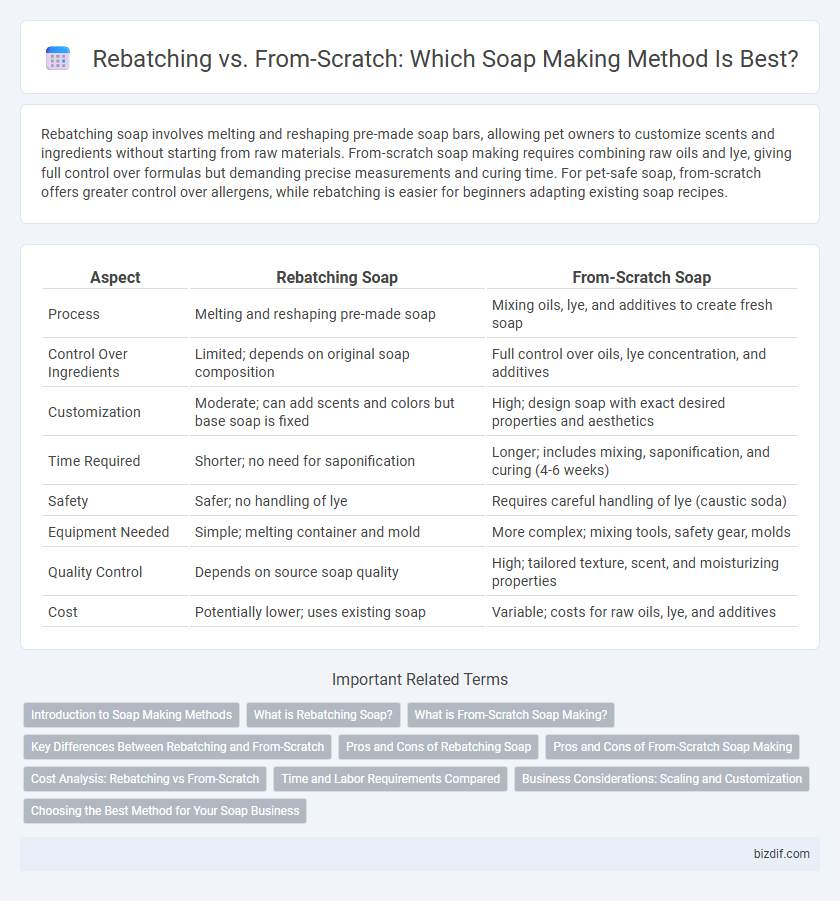

| Aspect | Rebatching Soap | From-Scratch Soap |

|---|---|---|

| Process | Melting and reshaping pre-made soap | Mixing oils, lye, and additives to create fresh soap |

| Control Over Ingredients | Limited; depends on original soap composition | Full control over oils, lye concentration, and additives |

| Customization | Moderate; can add scents and colors but base soap is fixed | High; design soap with exact desired properties and aesthetics |

| Time Required | Shorter; no need for saponification | Longer; includes mixing, saponification, and curing (4-6 weeks) |

| Safety | Safer; no handling of lye | Requires careful handling of lye (caustic soda) |

| Equipment Needed | Simple; melting container and mold | More complex; mixing tools, safety gear, molds |

| Quality Control | Depends on source soap quality | High; tailored texture, scent, and moisturizing properties |

| Cost | Potentially lower; uses existing soap | Variable; costs for raw oils, lye, and additives |

Introduction to Soap Making Methods

Rebatching involves melting down pre-made soap to reshape and customize it, offering a convenient method for beginners or small-scale crafters. From-scratch soap making uses the cold or hot process method, where raw ingredients like oils, lye, and water combine through saponification to create fresh soap bars. Both techniques allow soapmakers to control additives, scents, and textures, but from-scratch soap provides greater flexibility for formulating unique recipes.

What is Rebatching Soap?

Rebatching soap involves melting down pre-made soap bars and reshaping them by adding oils, fragrances, or colorants, allowing customization without starting from raw ingredients. This method preserves the original soap's finished qualities while enabling soapmakers to fix mistakes or incorporate new additives. Rebatching differs from from-scratch soap making, where raw oils and lye are combined and saponified to create soap from the beginning.

What is From-Scratch Soap Making?

From-scratch soap making involves creating soap by combining oils and lye through a chemical process called saponification, allowing full control over ingredients and customization. This method requires precise measurements, safety precautions, and curing time for the soap to harden and become usable. It offers the advantage of tailoring scents, textures, and additives to produce unique, natural soap bars.

Key Differences Between Rebatching and From-Scratch

Rebatching involves melting and reshaping pre-made soap, allowing for customization without handling raw lye, whereas from-scratch soap making requires saponifying oils with lye, offering full control over ingredients and formulations. Rebatching is ideal for salvaging batches or adding delicate additives, while from-scratch offers greater flexibility in creating unique soap bases and controlling the chemical process. Key differences include the safety level, ingredient control, and time investment, with from-scratch being more complex but offering superior customization.

Pros and Cons of Rebatching Soap

Rebatching soap involves grating and melting previously cured soap, allowing for customization by adding fragrances or additives without starting from raw ingredients. This method offers the advantage of troubleshooting batches with imperfections and extending the life of leftover soaps, but it consumes more time and energy compared to from-scratch soap making. However, rebatching limits control over the saponification process, potentially affecting final soap quality and texture.

Pros and Cons of From-Scratch Soap Making

From-scratch soap making offers complete control over ingredient selection, allowing crafters to customize scents, textures, and skin benefits with natural oils and additives. This method ensures a higher quality product but requires precise measurements, safety precautions for handling lye, and a longer curing time of typically 4-6 weeks. Despite its complexity and time investment, from-scratch soap making yields durable, moisturizing bars that can be tailored for specific skin types and preferences.

Cost Analysis: Rebatching vs From-Scratch

Rebatching soap involves melting and reforming pre-made soap, leading to lower initial ingredient costs and reduced waste compared to the from-scratch method, which requires precise raw material measurements and longer cure times that increase overhead. From-scratch soap production demands investment in raw oils, lye, and additives, often resulting in higher upfront expenses but offers greater customization and potentially higher product value. Cost efficiency in rebatching comes from repurposing unsold or imperfect batches, minimizing material losses, while from-scratch processes incur more variable costs tied to sourcing fresh ingredients and maintaining quality control.

Time and Labor Requirements Compared

Rebatching soap requires less time and effort as it involves melting and reforming pre-made soap bars, eliminating the need for handling lye and curing from scratch. From-scratch soap making demands more labor-intensive steps, including precise ingredient measurement, mixing lye with oils, and curing the soap for 4 to 6 weeks. Soap makers often choose rebatching for quicker production and smaller batches, while from-scratch yields more control over formulation and ingredient customization.

Business Considerations: Scaling and Customization

Rebatching soap allows small-scale businesses to minimize waste and customize batches by incorporating unique additives, but it limits large-scale production efficiency. From-scratch soap making offers greater scalability and flexibility in ingredient control, supporting brand differentiation through tailored formulations. Entrepreneurs prioritize from-scratch methods when seeking volume growth and full customization, while rebatching suits niche markets focusing on artisanal qualities.

Choosing the Best Method for Your Soap Business

Choosing between rebatching and from-scratch soap making depends on your business goals and resources. Rebatching offers quicker turnaround and reduces waste by using pre-made soap bases, ideal for small batches and customizations, while from-scratch soap making provides full control over ingredients and formulation, enhancing product uniqueness and quality. Evaluating production scale, cost-efficiency, and desired product differentiation will guide the optimal method for your soap business.

Rebatching vs From-Scratch Infographic

bizdif.com

bizdif.com