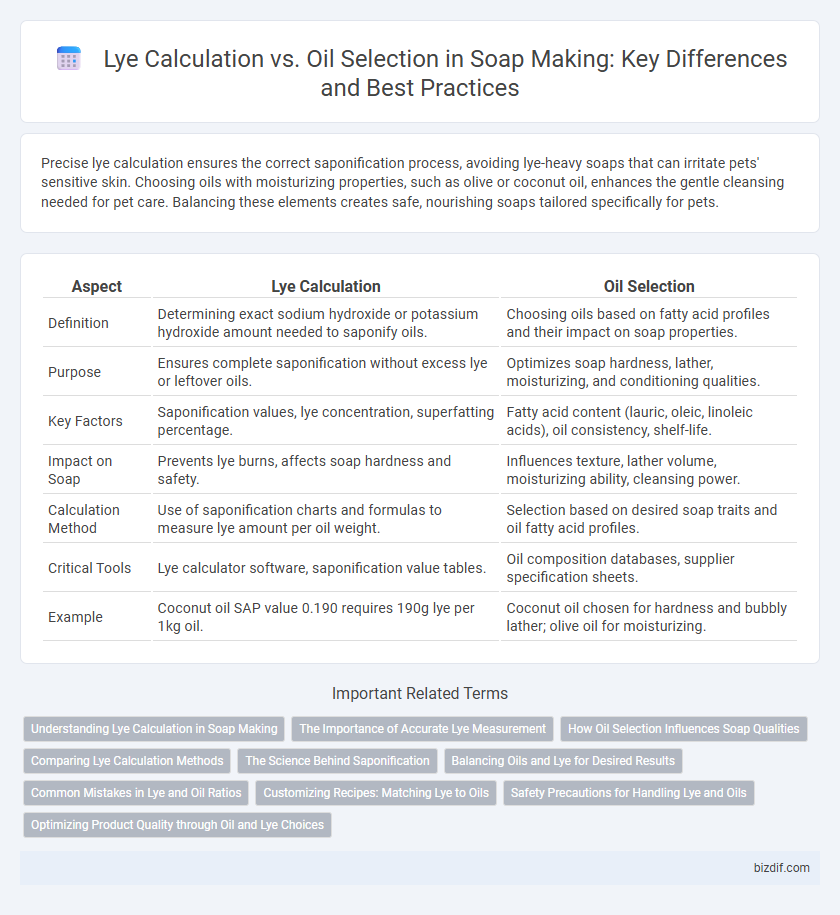

Precise lye calculation ensures the correct saponification process, avoiding lye-heavy soaps that can irritate pets' sensitive skin. Choosing oils with moisturizing properties, such as olive or coconut oil, enhances the gentle cleansing needed for pet care. Balancing these elements creates safe, nourishing soaps tailored specifically for pets.

Table of Comparison

| Aspect | Lye Calculation | Oil Selection |

|---|---|---|

| Definition | Determining exact sodium hydroxide or potassium hydroxide amount needed to saponify oils. | Choosing oils based on fatty acid profiles and their impact on soap properties. |

| Purpose | Ensures complete saponification without excess lye or leftover oils. | Optimizes soap hardness, lather, moisturizing, and conditioning qualities. |

| Key Factors | Saponification values, lye concentration, superfatting percentage. | Fatty acid content (lauric, oleic, linoleic acids), oil consistency, shelf-life. |

| Impact on Soap | Prevents lye burns, affects soap hardness and safety. | Influences texture, lather volume, moisturizing ability, cleansing power. |

| Calculation Method | Use of saponification charts and formulas to measure lye amount per oil weight. | Selection based on desired soap traits and oil fatty acid profiles. |

| Critical Tools | Lye calculator software, saponification value tables. | Oil composition databases, supplier specification sheets. |

| Example | Coconut oil SAP value 0.190 requires 190g lye per 1kg oil. | Coconut oil chosen for hardness and bubbly lather; olive oil for moisturizing. |

Understanding Lye Calculation in Soap Making

Accurate lye calculation is crucial in soap making to ensure the proper saponification of oils, preventing harsh or unbalanced soap. Understanding the correct amount of sodium hydroxide (lye) required depends on the saponification value (SAP) of each selected oil, which determines how much lye is needed to convert oils into soap without excess alkali. Precise lye calculation tailored to the specific oil selection guarantees a safe, high-quality final product with ideal hardness, lather, and moisturizing properties.

The Importance of Accurate Lye Measurement

Precise lye calculation is crucial for safe and effective soap making, as incorrect lye amounts can cause harsh, unusable bars or greasy, under-cured soap. Accurate measurement ensures complete saponification, optimizing the reaction between oils and lye to produce a balanced, gentle bar with desired qualities. Selecting the right oils requires matching their saponification values with the exact lye quantity to maintain soap quality and safety.

How Oil Selection Influences Soap Qualities

Oil selection determines key soap qualities such as hardness, lather, and moisturizing properties by influencing the fatty acid profile incorporated during lye calculation. Oils rich in saturated fats like coconut oil increase hardness and cleansing ability, while unsaturated oils such as olive oil contribute to conditioning and creaminess. Accurate lye calculation must adjust for each oil's saponification value to ensure optimal soap texture and longevity.

Comparing Lye Calculation Methods

Accurate lye calculation ensures proper saponification by determining the correct amount of sodium hydroxide needed for each oil's unique fatty acid profile. Common methods include the SAP value approach, which uses standardized saponification values, and the more precise titration method, directly measuring hydroxide requirements based on the oil's composition. Comparing these methods reveals that titration offers greater accuracy for custom or exotic oils, while SAP values provide reliable estimates for conventional soap making.

The Science Behind Saponification

Precise lye calculation is crucial in soap making to achieve proper saponification, the chemical reaction where lye (sodium hydroxide) reacts with oils or fats to produce soap and glycerin. Selecting oils with different fatty acid profiles influences the soap's hardness, lather quality, and moisturizing properties, directly affecting the saponification value used in the calculation. Understanding the balance between lye concentration and oil types ensures complete conversion without excess lye, resulting in safe and effective handcrafted soap.

Balancing Oils and Lye for Desired Results

Balancing oils and lye calculations is critical for achieving desired soap qualities such as hardness, lather, and moisturizing properties. Precise lye calculation ensures complete saponification without excess causticity, while oil selection determines the soap's final texture and skin benefits. Combining oils with varied fatty acid profiles and adjusting the lye amount based on their saponification values optimizes soap performance and safety.

Common Mistakes in Lye and Oil Ratios

Incorrect lye calculation or oil selection often leads to imbalanced soap batches with excess lye causing harshness or insufficient cleansing, while overly large oil quantities can result in greasy, soft bars. A common mistake involves misjudging the saponification values (SAP) of oils, leading to inaccurate lye amounts that affect the soap's final texture and safety. Precise measurement of both lye and oils based on their specific SAP numbers is crucial to achieve optimal soap hardness, moisturizing properties, and pH balance.

Customizing Recipes: Matching Lye to Oils

Precise lye calculation is critical in soap making to ensure complete saponification of selected oils, preventing excess lye and potential skin irritation. Different oils require specific amounts of lye, quantified by their unique saponification values, influencing the soap's hardness, lather, and moisturizing properties. Customizing soap recipes by accurately matching lye to oil blends optimizes the balance between cleansing efficacy and skin care benefits, resulting in a high-quality, tailored soap product.

Safety Precautions for Handling Lye and Oils

Accurate lye calculation is crucial to ensure a safe saponification process and prevent caustic burns when handling sodium hydroxide. Selecting oils with known fatty acid profiles helps predict the soap's hardness and lather, reducing the risk of unreacted lye causing skin irritation. Proper safety precautions include wearing gloves, goggles, and working in a well-ventilated area to avoid exposure to lye fumes and oil splashes.

Optimizing Product Quality through Oil and Lye Choices

Precise lye calculation is essential to ensure complete saponification, preventing excess lye that can cause harshness or insufficient lye leading to greasy soap. Selecting oils with suitable fatty acid profiles, such as high oleic acid for conditioning and lauric acid for cleansing, directly influences soap hardness, lather, and moisturizing properties. Balancing lye concentration with tailored oil blends optimizes soap quality, enhancing user experience and product longevity.

Lye Calculation vs Oil Selection Infographic

bizdif.com

bizdif.com