Maintaining the right lye concentration is crucial in soap making to ensure complete saponification without excess lye that can irritate the skin. Water discount affects the lye concentration by reducing the amount of water, which speeds up trace and can make the soap harder faster. Balancing lye concentration and water discount enhances soap quality, creating a smooth texture and optimal curing time for pet-safe formulations.

Table of Comparison

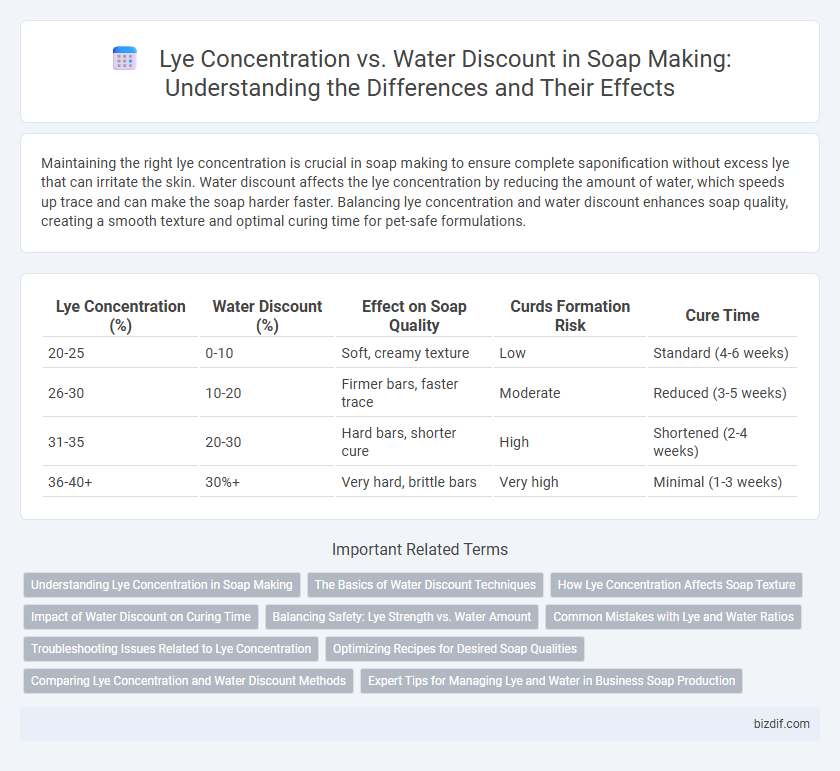

| Lye Concentration (%) | Water Discount (%) | Effect on Soap Quality | Curds Formation Risk | Cure Time |

|---|---|---|---|---|

| 20-25 | 0-10 | Soft, creamy texture | Low | Standard (4-6 weeks) |

| 26-30 | 10-20 | Firmer bars, faster trace | Moderate | Reduced (3-5 weeks) |

| 31-35 | 20-30 | Hard bars, shorter cure | High | Shortened (2-4 weeks) |

| 36-40+ | 30%+ | Very hard, brittle bars | Very high | Minimal (1-3 weeks) |

Understanding Lye Concentration in Soap Making

Lye concentration in soap making directly influences saponification, affecting both cure time and soap hardness; higher lye concentration reduces water content, speeding up the reaction but increasing the risk of a harsh bar. Water discount refers to the precise reduction of water in the recipe to achieve a specific lye concentration, optimizing the balance between workability and soap quality. Understanding the interplay between lye concentration and water discount allows soap makers to customize texture, trace time, and cure characteristics for superior handmade soaps.

The Basics of Water Discount Techniques

Water discount in soap making involves reducing the amount of water used to dissolve lye, which accelerates the saponification process and decreases curing time. Typical water discount techniques range from 10% to 30%, based on the total water in a recipe, balancing lye concentration to avoid overly harsh or crumbly soap. Optimizing water discount improves hardness and density of the final soap while maintaining proper chemical reactions with oils for a stable, high-quality bar.

How Lye Concentration Affects Soap Texture

Lye concentration directly influences soap texture by determining the soap's hardness and curing time; higher lye concentrations produce firmer bars with faster trace formation, while lower concentrations yield softer, creamier textures. Water discount reduces the amount of water in the recipe, increasing lye concentration and speeding up saponification, which can lead to a denser, less bubbly bar. Balancing lye concentration and water discount is crucial for achieving the desired soap hardness, smoothness, and longevity.

Impact of Water Discount on Curing Time

Water discount in soap making reduces the amount of water in the lye solution, leading to a thicker trace and faster saponification. This decrease in water content accelerates curing time by allowing excess moisture to evaporate more quickly, producing a harder, longer-lasting bar sooner. However, too high a water discount can cause soap to become brittle or develop cracking during curing.

Balancing Safety: Lye Strength vs. Water Amount

Maintaining an optimal lye concentration is essential for safety and effective soap saponification, as overly strong lye solutions can cause hazardous reactions, while excessive water dilutes lye strength, extending curing time. A typical water discount between 10-20% balances lye potency and manageable handling, reducing risks like skin burns without compromising soap quality. Careful measurement of lye concentration against water volume ensures controlled exothermic reactions, consistent soap texture, and safer working conditions during soap making.

Common Mistakes with Lye and Water Ratios

Incorrect lye concentration and improper water discount often lead to soap batches that are either too caustic or too soft, causing skin irritation or prolonged curing times. Many soap makers underestimate the impact of water discount on the lye concentration, which directly affects saponification and the soap's hardness. Accurate measurement of both sodium hydroxide (lye) and water is crucial to achieve balanced chemical reactions and optimal soap quality.

Troubleshooting Issues Related to Lye Concentration

Incorrect lye concentration in soap making causes common issues such as a soft or crumbly texture and excessive caustic soda remnants, leading to skin irritation. Water discount must be carefully balanced to maintain the proper lye concentration, as too little water increases concentration and accelerates trace, risking scorching and separation. Monitoring the precise ratio of lye to water ensures consistent saponification, preventing problems like soap that fails to cure correctly or develops a sticky surface.

Optimizing Recipes for Desired Soap Qualities

Balancing lye concentration and water discount is crucial for optimizing soap recipes to achieve desired textures and curing times. Higher lye concentrations with lower water discounts result in harder, denser bars that cure faster but require careful formulation to prevent brittleness. Adjusting these parameters influences saponification rates, ensuring soap qualities like hardness, lather, and moisturizing properties meet specific user preferences.

Comparing Lye Concentration and Water Discount Methods

Lye concentration and water discount methods both affect soap curing time and hardness by controlling water content in the batch. Lye concentration measures the amount of sodium hydroxide relative to the total solution, optimizing saponification efficiency, while water discount directly reduces water added, impacting trace time and consistency. Comparing these methods highlights lye concentration's precision in managing chemical balance versus water discount's straightforward adjustment for faster setting soap.

Expert Tips for Managing Lye and Water in Business Soap Production

Maintaining precise lye concentration is crucial for consistent soap quality, with a typical range of 25-30% lye concentration optimizing saponification while minimizing trace oils. Water discount strategies, reducing water content by 10-20%, accelerate curing time but require expert adjustment to prevent overly fast trace or separation. Professional soap makers balance lye concentration and water discount by testing small batches and measuring soap batter temperature to ensure controlled chemical reactions in scalable production.

Lye Concentration vs Water Discount Infographic

bizdif.com

bizdif.com