Melt and pour soap making involves using pre-made soap bases that are melted and customized with colors, scents, and additives, offering a quick and beginner-friendly approach. Made from scratch soap requires combining raw ingredients like oils, lye, and water through cold or hot process methods, allowing full control over formulation and quality. Each technique provides unique creative possibilities, with melt and pour offering convenience and made from scratch emphasizing craftsmanship and customization.

Table of Comparison

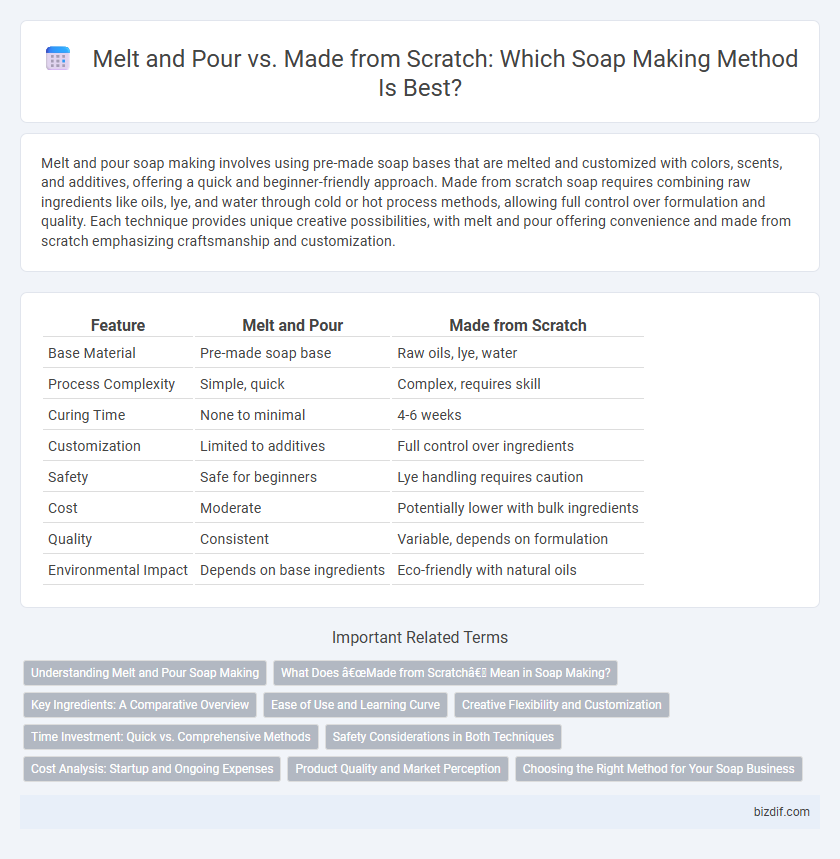

| Feature | Melt and Pour | Made from Scratch |

|---|---|---|

| Base Material | Pre-made soap base | Raw oils, lye, water |

| Process Complexity | Simple, quick | Complex, requires skill |

| Curing Time | None to minimal | 4-6 weeks |

| Customization | Limited to additives | Full control over ingredients |

| Safety | Safe for beginners | Lye handling requires caution |

| Cost | Moderate | Potentially lower with bulk ingredients |

| Quality | Consistent | Variable, depends on formulation |

| Environmental Impact | Depends on base ingredients | Eco-friendly with natural oils |

Understanding Melt and Pour Soap Making

Melt and pour soap making involves using a pre-made soap base that is melted, customized with colors, scents, and additives, then poured into molds to harden, offering a straightforward and time-efficient process ideal for beginners. This method eliminates the need for handling lye, reducing safety risks and complexity compared to made-from-scratch soap, which requires precise chemical reactions between lye and oils. Melt and pour soap bases often consist of glycerin, providing moisturizing properties and allowing for greater creativity with embeds and swirls during customization.

What Does “Made from Scratch” Mean in Soap Making?

"Made from scratch" in soap making refers to creating soap by combining individual raw ingredients such as oils, lye, and water, allowing full control over formulation and ingredients. Unlike melt and pour, which uses a pre-made glycerin base, made from scratch involves saponification--the chemical reaction between fats and lye--resulting in a customizable, artisanal product. This method offers benefits like ingredient transparency, the ability to tailor scents and textures, and the potential for natural, additive-free soap bars.

Key Ingredients: A Comparative Overview

Melt and pour soap primarily uses pre-made glycerin soap bases combined with added fragrances, colorants, and exfoliants, streamlining the soap making process. Made from scratch soap relies on raw ingredients such as oils, lye (sodium hydroxide), and distilled water, allowing for full control over chemical saponification and ingredient customization. The choice between these methods hinges on ingredient complexity, time investment, and desired customization in soap properties.

Ease of Use and Learning Curve

Melt and pour soap making offers a simple process ideal for beginners, requiring minimal equipment and no chemical handling, which significantly reduces the learning curve. Made from scratch soap making involves understanding complex measurements, lye safety, and chemical reactions, presenting a steeper learning curve but allowing greater customization. Choosing melt and pour accelerates soap crafting skills, while made from scratch rewards mastery with tailored formulations.

Creative Flexibility and Customization

Melt and Pour soap offers simplicity and speed but limits creative flexibility due to pre-made bases, restricting customization of ingredients and textures. In contrast, Made from Scratch soap allows complete control over formulation, enabling unique combinations of oils, scents, colors, and additives to tailor the soap to specific skin types and preferences. This extensive customization enhances the ability to experiment with innovative recipes and achieve personalized results in soap making.

Time Investment: Quick vs. Comprehensive Methods

Melt and pour soap making offers a quick time investment, allowing crafters to create finished bars within minutes by melting pre-made soap bases and adding desired ingredients. In contrast, made from scratch soap requires a comprehensive process involving precise mixing of oils, lye, and additives, followed by curing times that can span 4 to 6 weeks. This detailed method demands significant patience and planning but provides complete control over ingredients and customization.

Safety Considerations in Both Techniques

Melt and Pour soap making offers a safer approach by eliminating direct handling of lye, reducing chemical exposure risks common in Made from Scratch methods where precise lye measurement and handling are essential for safety. In Made from Scratch soap making, proper protective equipment such as gloves and goggles is critical due to the caustic nature of sodium hydroxide and the need for accurate chemical reactions. Both techniques require strict adherence to safety protocols to prevent burns and respiratory hazards, but Melt and Pour provides a more beginner-friendly environment with fewer risks related to chemical handling.

Cost Analysis: Startup and Ongoing Expenses

Melt and pour soap making requires lower startup costs due to pre-made soap bases, reducing the need for sourcing raw materials and specialized equipment. In contrast, made-from-scratch soap involves purchasing bulk oils, lye, and safety gear, leading to higher initial expenses but potentially lower ongoing costs per batch. Ongoing expenses for melt and pour remain relatively stable, while homemade soap costs vary with ingredient prices and batch sizes, impacting long-term profitability.

Product Quality and Market Perception

Melt and pour soap often features consistent texture and faster production time, appealing to beginners and small businesses seeking uniformity and efficiency. Made from scratch soap allows for customizable ingredients and natural formulations, resulting in higher perceived quality and unique branding that resonates with eco-conscious and premium market segments. Consumers tend to associate made-from-scratch soaps with artisanal craftsmanship and superior skin benefits, influencing market perception and willingness to pay a premium price.

Choosing the Right Method for Your Soap Business

Choosing the right soap making method impacts production efficiency and product customization in your soap business. Melt and Pour offers quick turnaround and ease of use, ideal for beginners or small batches, while Made from Scratch allows deep control over ingredients for unique, high-quality products. Understanding your target market and production scale helps determine the best approach that aligns with your brand values and business goals.

Melt and Pour vs Made from Scratch Infographic

bizdif.com

bizdif.com