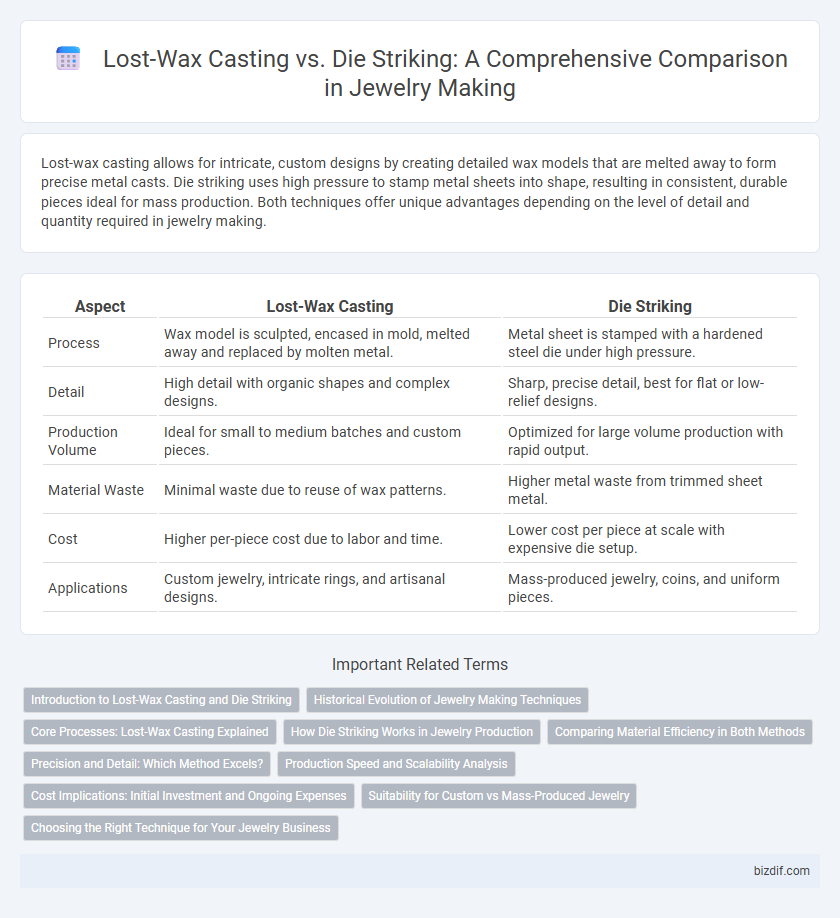

Lost-wax casting allows for intricate, custom designs by creating detailed wax models that are melted away to form precise metal casts. Die striking uses high pressure to stamp metal sheets into shape, resulting in consistent, durable pieces ideal for mass production. Both techniques offer unique advantages depending on the level of detail and quantity required in jewelry making.

Table of Comparison

| Aspect | Lost-Wax Casting | Die Striking |

|---|---|---|

| Process | Wax model is sculpted, encased in mold, melted away and replaced by molten metal. | Metal sheet is stamped with a hardened steel die under high pressure. |

| Detail | High detail with organic shapes and complex designs. | Sharp, precise detail, best for flat or low-relief designs. |

| Production Volume | Ideal for small to medium batches and custom pieces. | Optimized for large volume production with rapid output. |

| Material Waste | Minimal waste due to reuse of wax patterns. | Higher metal waste from trimmed sheet metal. |

| Cost | Higher per-piece cost due to labor and time. | Lower cost per piece at scale with expensive die setup. |

| Applications | Custom jewelry, intricate rings, and artisanal designs. | Mass-produced jewelry, coins, and uniform pieces. |

Introduction to Lost-Wax Casting and Die Striking

Lost-wax casting is a jewelry making process where a wax model is coated with a refractory material to create a mold, which is then heated to melt the wax away and filled with molten metal, enabling intricate and detailed designs. Die striking involves pressing precious metal blanks with high-pressure steel dies to form jewelry pieces, offering precision and consistency for simpler, flat designs. Each technique has distinct advantages in sculptural detail or mass production efficiency within the jewelry manufacturing industry.

Historical Evolution of Jewelry Making Techniques

Lost-wax casting, dating back over 5,000 years, revolutionized jewelry making by allowing intricate, three-dimensional designs through wax model melting and metal pouring. Die striking emerged in the 19th century with industrial advancements, enabling mass production of detailed and uniform jewelry pieces by stamping metal sheets using engraved dies. The historical evolution from artisanal lost-wax casting to mechanized die striking reflects a shift towards precision, scalability, and efficiency in jewelry manufacturing techniques.

Core Processes: Lost-Wax Casting Explained

Lost-wax casting is a core process in jewelry making where a detailed wax model is created and then encased in a heat-resistant mold. Once the mold is heated, the wax melts away, leaving a cavity that molten metal fills to form intricate designs. This method allows for high precision and fine detail, making it ideal for custom jewelry production and complex shapes not achievable through die striking.

How Die Striking Works in Jewelry Production

Die striking in jewelry production involves pressing a metal sheet into a hardened steel die under high pressure to create detailed and precise designs. This process ensures uniform thickness and sharp edges, making it ideal for producing high volumes of consistent pieces such as coins, badges, and rings. Compared to lost-wax casting, die striking offers faster production times and superior surface finishes without the need for melting or molding wax patterns.

Comparing Material Efficiency in Both Methods

Lost-wax casting offers superior material efficiency by allowing precise control over molten metal usage and minimizing waste through reusable wax models. Die striking, while faster for mass production, often generates more excess metal scraps due to the stamping process and trimming requirements. Comparing both methods highlights lost-wax casting's advantage in conserving precious metals, making it ideal for intricate, low-volume jewelry pieces.

Precision and Detail: Which Method Excels?

Lost-wax casting offers superior precision and intricate detail by allowing molten metal to flow into fine molds created from wax models, capturing complex designs and textures with exceptional accuracy. Die striking provides consistent precision for simpler, flatter shapes through high-pressure stamping but lacks the depth and fine surface detail achievable with lost-wax casting. For intricate jewelry designs demanding high-detail craftsmanship, lost-wax casting generally excels over die striking.

Production Speed and Scalability Analysis

Lost-wax casting offers slower production speed due to its intricate mold-making and wax model creation, making it ideal for limited runs and highly detailed jewelry. Die striking enables rapid, high-volume production by mechanically stamping metal sheets, providing superior scalability for mass-market jewelry lines. Manufacturers prioritize lost-wax casting for artisanal pieces and die striking for efficient, large-scale manufacturing demands.

Cost Implications: Initial Investment and Ongoing Expenses

Lost-wax casting requires a higher initial investment due to the need for custom molds and wax models, making it more suitable for complex or small-batch designs, while die striking demands expensive steel dies but benefits from faster production rates and lower per-piece costs for large quantities. Ongoing expenses in lost-wax casting include frequent mold replacements and wax consumption, whereas die striking incurs die maintenance and potential tool wear over time. Evaluating these cost implications helps jewelry makers balance upfront expenditures with long-term production efficiency and scalability.

Suitability for Custom vs Mass-Produced Jewelry

Lost-wax casting is highly suitable for custom jewelry due to its ability to capture intricate details and allow for design flexibility, making it ideal for one-of-a-kind or limited-edition pieces. Die striking excels in mass-produced jewelry by enabling fast, consistent production through high-pressure stamping, ensuring uniformity and efficiency for large-scale manufacturing. The choice between lost-wax casting and die striking hinges on balancing the need for detailed artistry with production volume demands.

Choosing the Right Technique for Your Jewelry Business

Lost-wax casting offers unparalleled detail and flexibility, ideal for custom and intricate jewelry designs, while die striking excels in high-volume production with precise, consistent results. Selecting between these methods depends on your business scale, design complexity, and budget constraints, as casting suits bespoke creations and die striking benefits mass manufacturing. Prioritizing the right technique enhances product quality, production efficiency, and customer satisfaction in your jewelry business.

Lost-wax casting vs Die striking Infographic

bizdif.com

bizdif.com