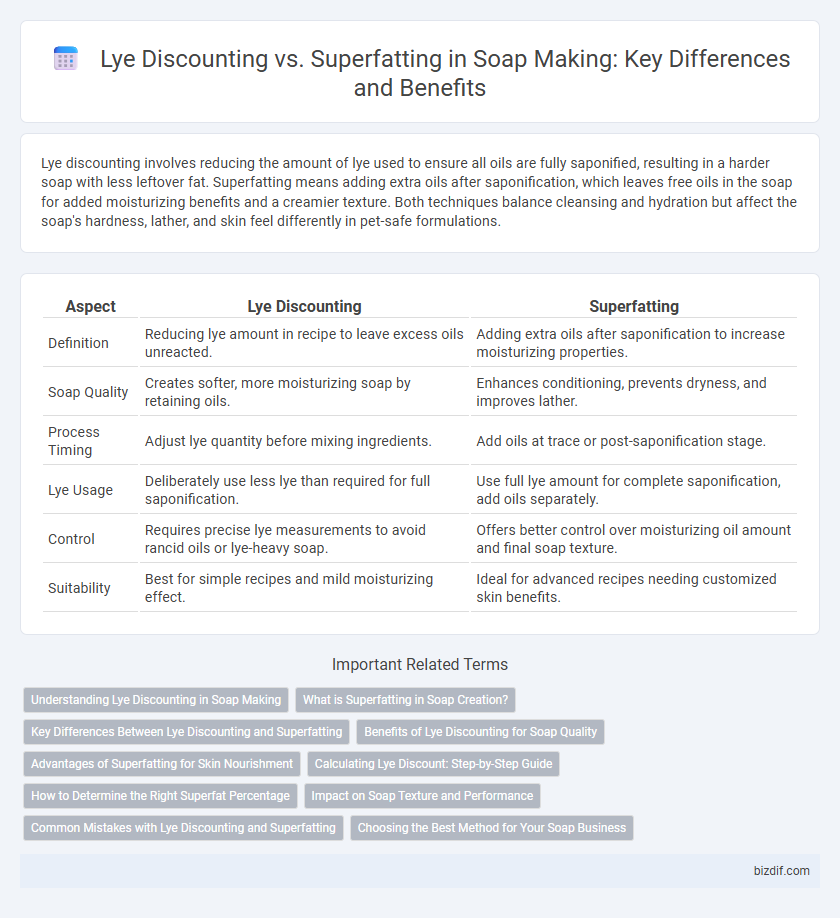

Lye discounting involves reducing the amount of lye used to ensure all oils are fully saponified, resulting in a harder soap with less leftover fat. Superfatting means adding extra oils after saponification, which leaves free oils in the soap for added moisturizing benefits and a creamier texture. Both techniques balance cleansing and hydration but affect the soap's hardness, lather, and skin feel differently in pet-safe formulations.

Table of Comparison

| Aspect | Lye Discounting | Superfatting |

|---|---|---|

| Definition | Reducing lye amount in recipe to leave excess oils unreacted. | Adding extra oils after saponification to increase moisturizing properties. |

| Soap Quality | Creates softer, more moisturizing soap by retaining oils. | Enhances conditioning, prevents dryness, and improves lather. |

| Process Timing | Adjust lye quantity before mixing ingredients. | Add oils at trace or post-saponification stage. |

| Lye Usage | Deliberately use less lye than required for full saponification. | Use full lye amount for complete saponification, add oils separately. |

| Control | Requires precise lye measurements to avoid rancid oils or lye-heavy soap. | Offers better control over moisturizing oil amount and final soap texture. |

| Suitability | Best for simple recipes and mild moisturizing effect. | Ideal for advanced recipes needing customized skin benefits. |

Understanding Lye Discounting in Soap Making

Lye discounting in soap making refers to intentionally reducing the amount of lye in the soap formula to ensure excess oils remain unsaponified, which produces a gentler, more moisturizing bar. This technique differs from superfatting, where extra oils are added to the recipe beyond what is needed to react with available lye, often post-lye mixture. Understanding lye discounting helps soap makers control the balance between cleansing power and moisturizing qualities by accurately calculating the reduced lye amount based on the desired oil content.

What is Superfatting in Soap Creation?

Superfatting in soap creation involves adding extra oils or fats beyond the amount needed to fully saponify the lye, resulting in a soap with increased moisturizing properties. This intentional excess of oils ensures the final product is gentler on the skin and less drying, as some oils remain unsaponified. The level of superfatting typically ranges from 3% to 8%, enhancing the soap's nourishing quality and improving its overall skin feel.

Key Differences Between Lye Discounting and Superfatting

Lye discounting involves reducing the amount of lye below the theoretical amount needed for complete saponification, ensuring all oils are fully converted while leaving a mild excess of fats. Superfatting, on the other hand, adds excess oils after saponification, creating extra moisturizing properties without the risk of leftover lye. The key difference lies in timing and process: lye discounting adjusts the lye from the start, whereas superfatting introduces additional oils post-saponification.

Benefits of Lye Discounting for Soap Quality

Lye discounting in soap making enhances the final product's moisturizing properties by leaving a controlled amount of unsaponified oils, resulting in a gentler bar. This technique improves the soap's hardness and creates a creamy lather, which contributes to a luxurious user experience. Maintaining precise lye discounting ensures better shelf stability and reduces the risk of skin irritation compared to over-superfatting.

Advantages of Superfatting for Skin Nourishment

Superfatting in soap making enhances skin nourishment by retaining a higher amount of natural oils and fats, which provide deep moisturizing benefits and help prevent dryness. This method increases the presence of antioxidants and fatty acids in the soap, promoting skin repair and protection against irritation. Compared to lye discounting, superfatting creates a gentler, more conditioning bar ideal for sensitive and dry skin types.

Calculating Lye Discount: Step-by-Step Guide

Calculating lye discount in soap making involves reducing the amount of lye below the theoretical requirement to leave unreacted oils, enhancing moisturizing properties. Start by determining the exact amount of oils and their saponification values, then multiply the total lye needed by the chosen discount percentage, typically between 5-10%. This precise adjustment ensures balanced soap hardness, cleansing ability, and superfatted richness for optimal skin benefits.

How to Determine the Right Superfat Percentage

Determining the right superfat percentage in soap making involves balancing the lye-to-oil ratio to ensure excess oils remain unsaponified, enhancing moisturizing properties without compromising soap hardness or shelf life. A typical superfat range is 3-5%, adjusted based on oil type, desired skin feel, and curing time, with higher percentages benefiting sensitive skin by providing extra conditioning. Accurate lye discounting calculations, considering oil saponification values, are essential to optimize superfat levels and achieve a stable, high-quality soap bar.

Impact on Soap Texture and Performance

Lye discounting alters the amount of lye in the recipe, resulting in a softer, more moisturizing bar due to excess oils but may sacrifice hardness and longevity. Superfatting involves adding extra oils after saponification begins, enhancing conditioning properties and creating a creamier texture without drastically affecting the soap's structural integrity. Both techniques influence the soap's performance by balancing cleansing power, moisturizing effects, and overall durability.

Common Mistakes with Lye Discounting and Superfatting

Common mistakes with lye discounting include underestimating the precise lye amount needed, leading to overly soft or oily soap. In superfatting, excessive oil addition without proper adjustment of lye can cause a greasy, unstable bar prone to spoilage. Accurate calculations and thorough understanding of saponification values are essential to avoid batch inconsistencies and ensure soap quality.

Choosing the Best Method for Your Soap Business

Choosing between lye discounting and superfatting depends on your soap formulation goals and target market preferences. Lye discounting reduces the amount of lye in the recipe, ensuring less alkali and a milder bar, while superfatting involves adding extra oils after saponification for enhanced moisturizing properties. Evaluating ingredient costs, desired bar qualities, and customer skin type demands will guide the optimal method selection for scaling your soap business.

Lye Discounting vs Superfatting Infographic

bizdif.com

bizdif.com