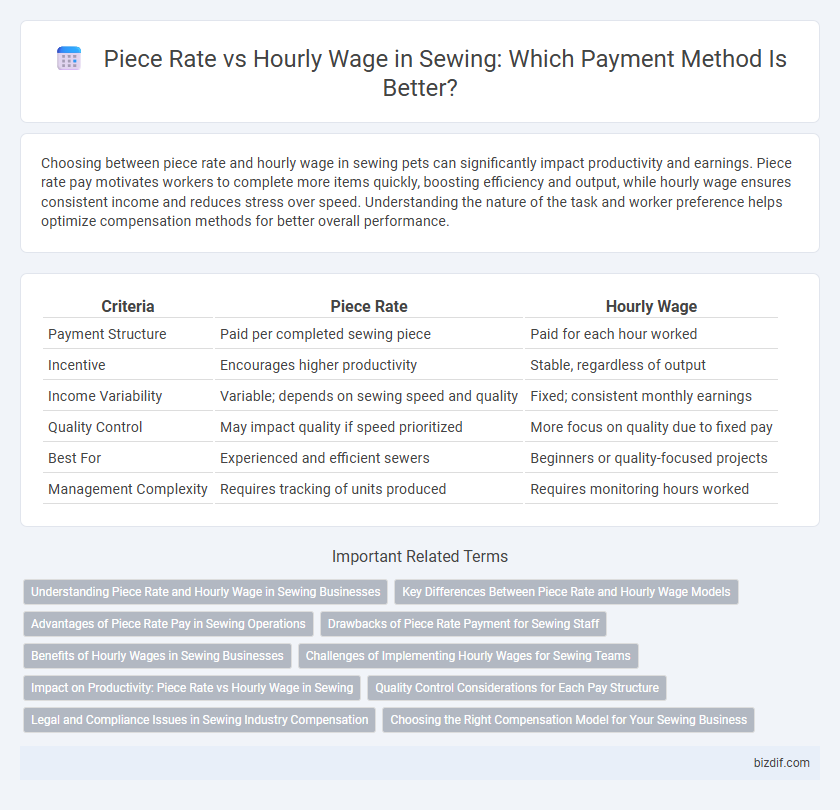

Choosing between piece rate and hourly wage in sewing pets can significantly impact productivity and earnings. Piece rate pay motivates workers to complete more items quickly, boosting efficiency and output, while hourly wage ensures consistent income and reduces stress over speed. Understanding the nature of the task and worker preference helps optimize compensation methods for better overall performance.

Table of Comparison

| Criteria | Piece Rate | Hourly Wage |

|---|---|---|

| Payment Structure | Paid per completed sewing piece | Paid for each hour worked |

| Incentive | Encourages higher productivity | Stable, regardless of output |

| Income Variability | Variable; depends on sewing speed and quality | Fixed; consistent monthly earnings |

| Quality Control | May impact quality if speed prioritized | More focus on quality due to fixed pay |

| Best For | Experienced and efficient sewers | Beginners or quality-focused projects |

| Management Complexity | Requires tracking of units produced | Requires monitoring hours worked |

Understanding Piece Rate and Hourly Wage in Sewing Businesses

Piece rate payment in sewing businesses compensates workers based on the number of garments or pieces completed, promoting higher productivity but potentially impacting sewing quality and worker consistency. Hourly wage offers stable income by paying workers for the time spent sewing regardless of output, supporting steady quality control and allowing for detailed craftsmanship in garment production. Understanding these payment methods helps sewing business owners balance cost efficiency, worker motivation, and product quality in manufacturing operations.

Key Differences Between Piece Rate and Hourly Wage Models

Piece rate compensation pays sewists based on the number of garments or pieces completed, incentivizing higher productivity and efficiency, while hourly wage guarantees a fixed income regardless of output. Piece rate models often lead to variable earnings tied directly to performance, whereas hourly wages provide consistent, predictable pay with less focus on speed. The choice between these systems impacts worker motivation, quality control, and overall labor costs within sewing operations.

Advantages of Piece Rate Pay in Sewing Operations

Piece rate pay in sewing operations incentivizes higher productivity by directly linking earnings to the number of garments completed, motivating workers to maintain speed and efficiency. This payment system reduces labor costs for manufacturers, as wages are strictly tied to output rather than time spent, minimizing downtime and boosting overall production capacity. Experienced sewists benefit from piece rate pay by maximizing their income potential through skillful and rapid stitching, creating a performance-driven environment that supports skill development and quality garment construction.

Drawbacks of Piece Rate Payment for Sewing Staff

Piece rate payment in sewing often leads to inconsistent income due to fluctuations in production speed and garment complexity, causing financial instability for workers. This system can promote rushed work, increasing defects and reducing overall product quality. It also discourages teamwork and skill development, as employees focus solely on quantity rather than craftsmanship or collaboration.

Benefits of Hourly Wages in Sewing Businesses

Hourly wages in sewing businesses provide consistent income stability, allowing workers to focus on quality and precision without rushing. This payment structure encourages thorough craftsmanship, reducing errors and material waste commonly seen with piece rate systems. Employers benefit from improved employee satisfaction and retention due to predictable earnings and fair compensation.

Challenges of Implementing Hourly Wages for Sewing Teams

Implementing hourly wages for sewing teams often faces challenges such as accurately tracking individual productivity and maintaining incentives for efficiency. Variations in skill levels and task complexity can lead to disparities in output, making uniform hourly pay less motivating. Furthermore, supervisors must invest time and resources in monitoring work pace and quality to ensure fairness and maintain overall production standards.

Impact on Productivity: Piece Rate vs Hourly Wage in Sewing

Piece rate compensation in sewing directly incentivizes workers to increase output by linking pay to the number of pieces completed, often resulting in higher productivity compared to hourly wages. Hourly wage systems provide financial stability but may lead to slower work pace as pay remains constant regardless of output. Studies in garment manufacturing reveal that piece rate systems can boost efficiency by up to 20%, promoting faster completion of sewing tasks without compromising quality.

Quality Control Considerations for Each Pay Structure

Piece rate payment in sewing incentivizes higher output but may compromise quality control due to faster, less meticulous work. Hourly wage structures allow workers to focus more on careful stitching and detailed quality checks without the pressure of meeting quantity targets. Implementing strict quality control protocols is essential regardless of pay type to maintain garment standards and reduce defects.

Legal and Compliance Issues in Sewing Industry Compensation

Piece rate compensation in the sewing industry often raises legal and compliance concerns, particularly regarding minimum wage laws and overtime regulations mandated by the Fair Labor Standards Act (FLSA). Employers must carefully track hours worked to ensure piece rate pay does not fall below the federal or state minimum wage, with noncompliance potentially resulting in wage theft claims and costly penalties. Compliance also involves maintaining accurate records and adhering to child labor laws, ensuring fair and lawful compensation practices in garment manufacturing.

Choosing the Right Compensation Model for Your Sewing Business

Selecting the appropriate compensation model for your sewing business impacts productivity and employee satisfaction. Piece rate pay incentivizes speed and can improve output quality for tasks like garment assembly, while hourly wages provide stability and encourage thorough craftsmanship on complex projects. Evaluating job complexity, production goals, and worker skill levels helps determine whether piece rate or hourly wage best aligns with your operational priorities and financial planning.

Piece rate vs Hourly wage Infographic

bizdif.com

bizdif.com