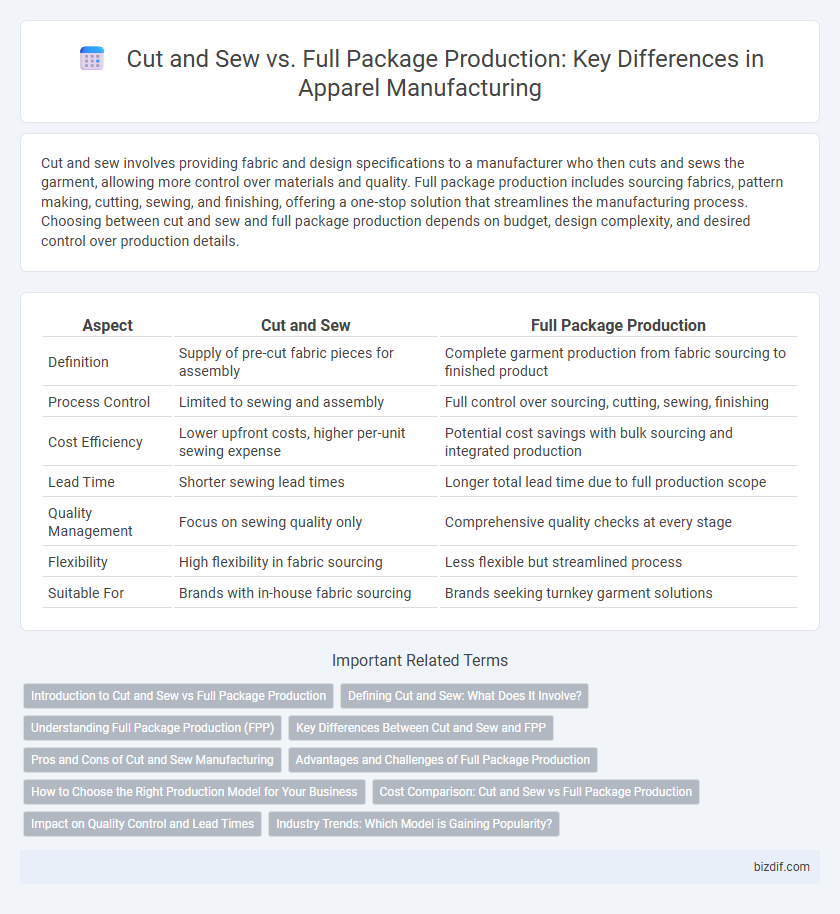

Cut and sew involves providing fabric and design specifications to a manufacturer who then cuts and sews the garment, allowing more control over materials and quality. Full package production includes sourcing fabrics, pattern making, cutting, sewing, and finishing, offering a one-stop solution that streamlines the manufacturing process. Choosing between cut and sew and full package production depends on budget, design complexity, and desired control over production details.

Table of Comparison

| Aspect | Cut and Sew | Full Package Production |

|---|---|---|

| Definition | Supply of pre-cut fabric pieces for assembly | Complete garment production from fabric sourcing to finished product |

| Process Control | Limited to sewing and assembly | Full control over sourcing, cutting, sewing, finishing |

| Cost Efficiency | Lower upfront costs, higher per-unit sewing expense | Potential cost savings with bulk sourcing and integrated production |

| Lead Time | Shorter sewing lead times | Longer total lead time due to full production scope |

| Quality Management | Focus on sewing quality only | Comprehensive quality checks at every stage |

| Flexibility | High flexibility in fabric sourcing | Less flexible but streamlined process |

| Suitable For | Brands with in-house fabric sourcing | Brands seeking turnkey garment solutions |

Introduction to Cut and Sew vs Full Package Production

Cut and sew production involves supplying pre-cut fabric pieces to manufacturers who then handle the sewing and assembly of garments, allowing brands to maintain control over fabric sourcing and design details. Full package production encompasses the end-to-end process, including fabric sourcing, cutting, sewing, finishing, and packaging, offering a turnkey solution for apparel businesses seeking streamlined operations. Both methods impact lead times, cost structures, and quality control strategies within the apparel manufacturing industry.

Defining Cut and Sew: What Does It Involve?

Cut and sew involves producing garments by cutting fabric pieces according to specific patterns and sewing them together, allowing for custom designs and material choices. This process requires precise pattern making, fabric selection, and skilled sewing operations to ensure quality and fit. Unlike full package production, cut and sew focuses solely on garment construction, excluding activities like sourcing or finishing.

Understanding Full Package Production (FPP)

Full Package Production (FPP) in sewing involves a comprehensive process where manufacturers handle everything from fabric sourcing and pattern making to cutting, sewing, and final garment finishing. This end-to-end approach ensures streamlined production, reduces lead times, and minimizes coordination efforts for brands or designers. FPP contrasts with Cut and Sew, which requires clients to provide materials and patterns, placing more responsibility on them for the garment's initial stages.

Key Differences Between Cut and Sew and FPP

Cut and Sew and Full Package Production differ primarily in scope and responsibility. Cut and Sew involves providing pre-cut fabrics for sewing, focusing on garment assembly, while Full Package Production manages the entire process from fabric sourcing, cutting, sewing, to finishing and packaging. Full Package Production offers a comprehensive solution, streamlining supply chain management and quality control compared to the more limited services in Cut and Sew.

Pros and Cons of Cut and Sew Manufacturing

Cut and sew manufacturing offers greater control over fabric selection and design customization, enabling brands to achieve unique textures and finishes. It demands more involvement in sourcing and quality control, potentially increasing lead times and production complexity. This method suits businesses prioritizing flexibility and craftsmanship but may not be cost-effective for large-scale or fully managed production needs.

Advantages and Challenges of Full Package Production

Full Package Production offers significant advantages such as streamlined supply chain management, reduced coordination efforts, and faster time-to-market by integrating sourcing, cutting, sewing, and finishing under one vendor. This production method enhances quality control and scalability, allowing brands to focus on design and marketing without managing multiple suppliers. Challenges include less direct oversight, potential dependency on the manufacturer's capacity, and risks related to supply chain transparency and cost fluctuations.

How to Choose the Right Production Model for Your Business

Choosing between Cut and Sew and Full Package Production depends on your business goals, budget, and control needs. Cut and Sew allows greater customization and quality oversight by handling fabric sourcing and cutting independently, ideal for brands prioritizing design precision. Full Package Production streamlines the process by outsourcing sourcing, cutting, and sewing, saving time and reducing complexity for businesses focused on quick market entry.

Cost Comparison: Cut and Sew vs Full Package Production

Cut and sew production typically involves purchasing pre-cut fabric and assembling garments, which can lower initial costs by reducing material waste and cutting labor expenses. Full package production includes end-to-end services from fabric sourcing to finished products, often leading to higher costs due to comprehensive management and quality control. Comparing costs reveals that cut and sew is generally more economical for smaller runs, while full package offers scalability and efficiency for large-volume orders despite increased upfront investment.

Impact on Quality Control and Lead Times

Cut and Sew production offers greater control over quality by managing individual components, allowing for precise inspection at each stage but often results in longer lead times due to its segmented process. Full Package Production consolidates all steps from fabric sourcing to garment assembly under one provider, which can streamline lead times and simplify coordination but may pose challenges in maintaining consistent quality across outsourced suppliers. Choosing between Cut and Sew and Full Package Production hinges on balancing the need for meticulous quality control with the desire for faster turnaround times in garment manufacturing.

Industry Trends: Which Model is Gaining Popularity?

Cut and sew production offers brands greater control over fabric sourcing and design customization, appealing to niche markets and sustainable fashion trends. Full package production streamlines the supply chain by integrating fabric procurement, cutting, sewing, and finishing, gaining popularity among fast fashion and large-scale manufacturers for its efficiency. Industry data shows a growing shift towards full package production due to rising demand for quick turnaround times and cost-effective solutions in global apparel manufacturing.

Cut and Sew vs Full Package Production Infographic

bizdif.com

bizdif.com