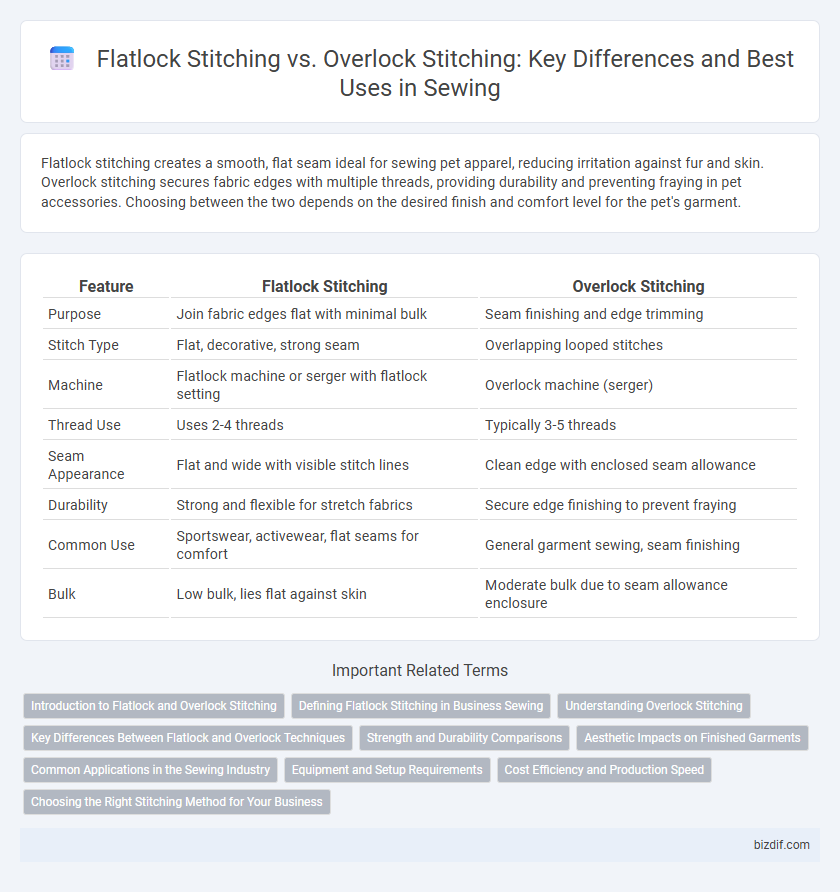

Flatlock stitching creates a smooth, flat seam ideal for sewing pet apparel, reducing irritation against fur and skin. Overlock stitching secures fabric edges with multiple threads, providing durability and preventing fraying in pet accessories. Choosing between the two depends on the desired finish and comfort level for the pet's garment.

Table of Comparison

| Feature | Flatlock Stitching | Overlock Stitching |

|---|---|---|

| Purpose | Join fabric edges flat with minimal bulk | Seam finishing and edge trimming |

| Stitch Type | Flat, decorative, strong seam | Overlapping looped stitches |

| Machine | Flatlock machine or serger with flatlock setting | Overlock machine (serger) |

| Thread Use | Uses 2-4 threads | Typically 3-5 threads |

| Seam Appearance | Flat and wide with visible stitch lines | Clean edge with enclosed seam allowance |

| Durability | Strong and flexible for stretch fabrics | Secure edge finishing to prevent fraying |

| Common Use | Sportswear, activewear, flat seams for comfort | General garment sewing, seam finishing |

| Bulk | Low bulk, lies flat against skin | Moderate bulk due to seam allowance enclosure |

Introduction to Flatlock and Overlock Stitching

Flatlock stitching creates a flat seam by joining fabric edges with visible parallel lines, ideal for activewear and stretch fabrics. Overlock stitching trims and sews fabric edges simultaneously, preventing fraying and producing clean, durable finishes in knitwear and woven materials. Both techniques enhance garment durability while catering to specific fabric types and aesthetic needs.

Defining Flatlock Stitching in Business Sewing

Flatlock stitching in business sewing creates a flat seam by overlapping fabric edges and sewing through all layers, offering durability and a smooth finish ideal for activewear and stretch fabrics. Unlike overlock stitching, which trims fabric edges while enclosing them with thread, flatlock stitching minimizes bulk and enhances flexibility, making it preferred for garments requiring comfort and clean seams. This technique improves garment lifespan and aesthetic appeal, reinforcing brand quality in competitive apparel markets.

Understanding Overlock Stitching

Overlock stitching creates strong, stretchable seams by simultaneously trimming excess fabric and encasing the raw edges with thread, preventing fraying and ensuring durability. This stitch is commonly used in garment construction for knit and woven fabrics, offering a professional finish and enhanced fabric stability. The multiple-thread design of overlock machines allows for efficient seam reinforcement, making it essential for high-quality apparel manufacturing.

Key Differences Between Flatlock and Overlock Techniques

Flatlock stitching creates a flat seam by overlapping fabric edges and sewing through all layers, ideal for sportswear and stretch fabrics due to its flexibility and comfort. Overlock stitching trims the fabric edges while sewing, producing a neater finish and preventing fraying, commonly used for garment construction and edge finishing. Key differences include seam appearance, fabric edge treatment, and stretchability, with flatlock seams lying flat and overlock seams providing durability and edge reinforcement.

Strength and Durability Comparisons

Flatlock stitching creates a strong, flat seam by interlocking multiple threads, ideal for stretch fabrics and activewear, providing excellent durability without bulk. Overlock stitching trims the fabric edge while binding, offering moderate strength but superior edge finishing that prevents fraying in woven and knit materials. In terms of long-term wear, flatlock seams tend to maintain integrity better under constant stress, whereas overlock seams excel in preventing fabric damage and extending garment lifespan.

Aesthetic Impacts on Finished Garments

Flatlock stitching creates a smooth, flat seam that sits flush against the fabric, giving finished garments a sleek and modern aesthetic ideal for activewear and seamless looks. Overlock stitching produces a raised, reinforced edge that enhances durability while adding a decorative, textured finish often visible on hems and inside seams. The choice between these techniques impacts not only the structural integrity but also the visual appeal, with flatlock emphasizing seamlessness and overlock highlighting craftsmanship.

Common Applications in the Sewing Industry

Flatlock stitching is widely used in activewear and sportswear for its flat, comfortable seams that reduce chafing during physical activity. Overlock stitching is common in garment manufacturing for finishing raw edges, preventing fraying, and providing durable seam construction in a variety of fabrics. Both stitching techniques enhance garment quality and longevity but serve different purposes based on fabric type and design requirements.

Equipment and Setup Requirements

Flatlock stitching requires specialized flatlock machines designed to create seams that lie flat without bulk, often used in activewear and stretchy fabrics, whereas overlock stitching utilizes overlock machines equipped with multiple loopers and knives for trimming and finishing edges simultaneously. Flatlock machines generally have simpler threading and tension adjustments but need precise fabric alignment to achieve the characteristic flat seam. Overlock machines demand more complex setup with thread trimming and differential feed settings to accommodate various fabric types and seam strengths.

Cost Efficiency and Production Speed

Flatlock stitching offers cost efficiency by using fewer threads and simpler machinery, reducing material expenses and maintenance costs. Overlock stitching significantly increases production speed due to its ability to sew and trim fabric edges simultaneously, making it ideal for high-volume garment manufacturing. Choosing between the two depends on balancing lower operational costs with faster output requirements in sewing projects.

Choosing the Right Stitching Method for Your Business

Flatlock stitching provides a smooth, flat seam ideal for activewear and garments requiring minimal bulk, enhancing comfort and flexibility. Overlock stitching offers durability and efficient edge finishing, perfect for high-volume production and preventing fabric fraying in woven and knit materials. Choosing the right method depends on fabric type, garment function, and production scale to optimize quality and cost-effectiveness in your business.

Flatlock stitching vs Overlock stitching Infographic

bizdif.com

bizdif.com