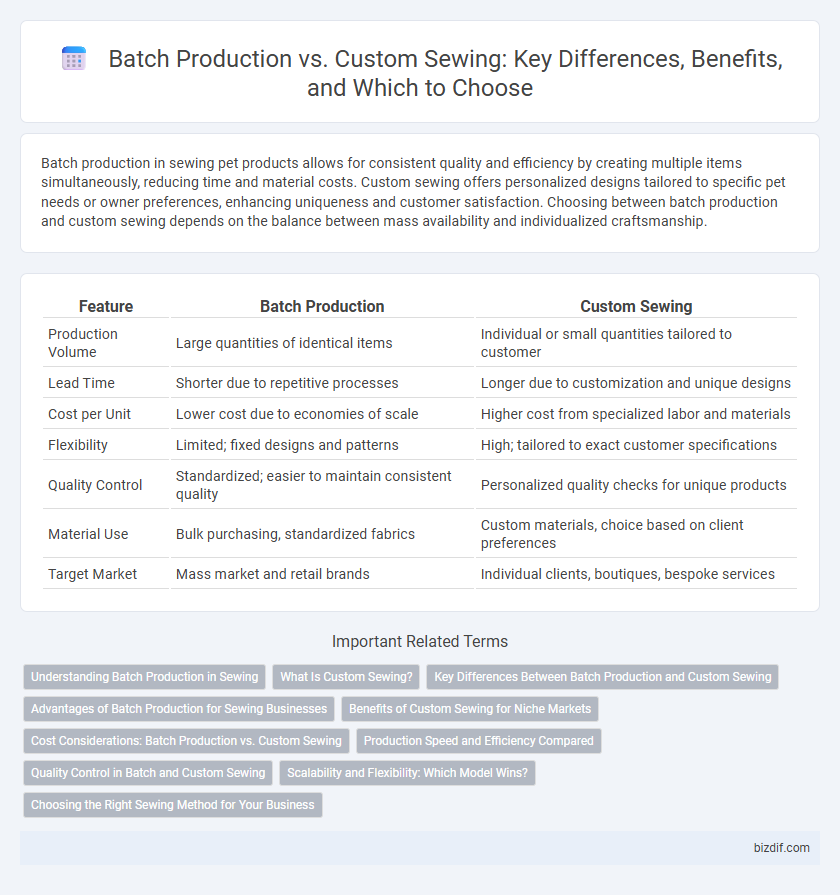

Batch production in sewing pet products allows for consistent quality and efficiency by creating multiple items simultaneously, reducing time and material costs. Custom sewing offers personalized designs tailored to specific pet needs or owner preferences, enhancing uniqueness and customer satisfaction. Choosing between batch production and custom sewing depends on the balance between mass availability and individualized craftsmanship.

Table of Comparison

| Feature | Batch Production | Custom Sewing |

|---|---|---|

| Production Volume | Large quantities of identical items | Individual or small quantities tailored to customer |

| Lead Time | Shorter due to repetitive processes | Longer due to customization and unique designs |

| Cost per Unit | Lower cost due to economies of scale | Higher cost from specialized labor and materials |

| Flexibility | Limited; fixed designs and patterns | High; tailored to exact customer specifications |

| Quality Control | Standardized; easier to maintain consistent quality | Personalized quality checks for unique products |

| Material Use | Bulk purchasing, standardized fabrics | Custom materials, choice based on client preferences |

| Target Market | Mass market and retail brands | Individual clients, boutiques, bespoke services |

Understanding Batch Production in Sewing

Batch production in sewing involves creating multiple identical garments in set quantities, maximizing efficiency through repeated use of the same materials, patterns, and machinery setups. This method reduces per-unit costs and lead times compared to custom sewing, which focuses on single, personalized pieces tailored to individual specifications. Efficient inventory management and standardized quality control are key advantages in batch production, making it ideal for ready-to-wear clothing lines and large-scale manufacturing.

What Is Custom Sewing?

Custom sewing involves creating garments or textile products tailored specifically to individual measurements, preferences, and design specifications, ensuring a unique and personalized fit. Unlike batch production, which manufactures large quantities of identical items, custom sewing emphasizes quality craftsmanship and attention to detail for each piece. This approach is ideal for bespoke clothing, alterations, and specialized orders where precision and customization are paramount.

Key Differences Between Batch Production and Custom Sewing

Batch production in sewing involves creating multiple identical garments simultaneously, enhancing efficiency and reducing per-unit costs through standardized processes. Custom sewing, on the other hand, focuses on individualized garment creation tailored to specific measurements and design preferences, prioritizing uniqueness over volume. Key differences include production scale, turnaround time, cost per piece, and the level of personalization offered to the customer.

Advantages of Batch Production for Sewing Businesses

Batch production in sewing businesses enables higher efficiency by producing multiple identical garments simultaneously, reducing production time and labor costs compared to custom sewing. It allows for consistent quality control and standardized output, which is crucial for meeting large order demands and maintaining brand reputation. Inventory management becomes more streamlined, facilitating bulk material purchases that lower raw material costs and ensure steady supply chains.

Benefits of Custom Sewing for Niche Markets

Custom sewing offers unparalleled advantages for niche markets by enabling highly specialized garment production tailored to unique customer preferences, ensuring perfect fit and exclusive designs. This personalized approach reduces fabric waste and enhances product quality, leading to higher customer satisfaction and brand loyalty. Small batch runs in custom sewing also provide agile response to market trends without the risks associated with mass inventory, making it ideal for niche market demands.

Cost Considerations: Batch Production vs. Custom Sewing

Batch production significantly lowers per-unit costs by maximizing efficiency through repetitive processes and bulk material purchases, making it ideal for high-volume orders. Custom sewing incurs higher expenses due to specialized labor, unique material sourcing, and longer production times tailored to individual specifications. Evaluating cost considerations between batch production and custom sewing hinges on order volume, design complexity, and the necessity for personalization.

Production Speed and Efficiency Compared

Batch production in sewing maximizes production speed and efficiency by processing large quantities of identical items, enabling streamlined workflows and reduced setup times. Custom sewing prioritizes individualized garment details, resulting in slower production speeds and lower efficiency due to frequent machine adjustments and labor-intensive techniques. Factories employing batch production achieve higher throughput rates, optimizing resource utilization and minimizing production costs per unit.

Quality Control in Batch and Custom Sewing

Quality control in batch production sewing emphasizes standardized processes and uniform inspection criteria to ensure consistent garment quality across large quantities. Custom sewing quality control focuses on meticulous craftsmanship and personalized adjustments, enabling high accuracy and attention to detail for unique, one-of-a-kind pieces. Both methods implement thorough inspections, but batch production relies on repeatability, while custom sewing prioritizes individualized precision.

Scalability and Flexibility: Which Model Wins?

Batch production excels in scalability by enabling mass garment output through standardized processes and bulk fabric cutting, ideal for meeting high-volume demands efficiently. Custom sewing offers unmatched flexibility, allowing tailored designs and adjustments for individual preferences but at the cost of slower production rates and higher per-unit costs. When balancing scalability and flexibility, batch production wins in volume-driven markets, while custom sewing dominates niches requiring personalized craftsmanship.

Choosing the Right Sewing Method for Your Business

Batch production sewing maximizes efficiency by producing large quantities of identical garments, reducing per-unit costs and streamlining workflow for businesses with consistent demand. Custom sewing offers flexibility and personalization, allowing for unique designs and tailored fits that cater to niche markets or specific customer preferences. Selecting the right sewing method depends on factors such as order volume, budget constraints, target audience, and desired product differentiation to optimize profitability and customer satisfaction.

Batch production vs Custom sewing Infographic

bizdif.com

bizdif.com