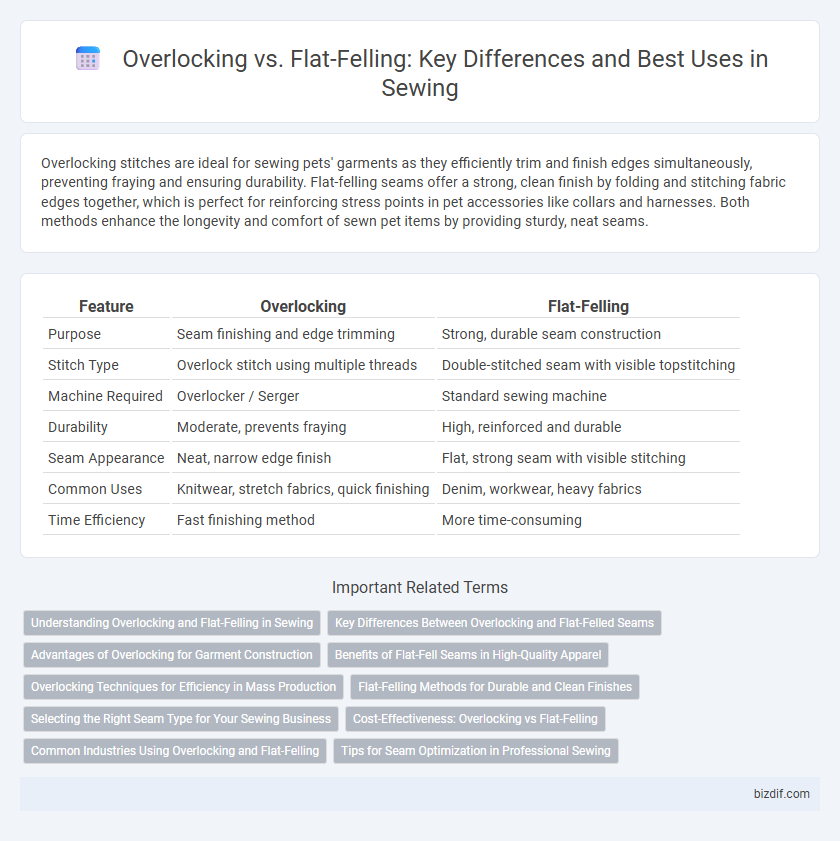

Overlocking stitches are ideal for sewing pets' garments as they efficiently trim and finish edges simultaneously, preventing fraying and ensuring durability. Flat-felling seams offer a strong, clean finish by folding and stitching fabric edges together, which is perfect for reinforcing stress points in pet accessories like collars and harnesses. Both methods enhance the longevity and comfort of sewn pet items by providing sturdy, neat seams.

Table of Comparison

| Feature | Overlocking | Flat-Felling |

|---|---|---|

| Purpose | Seam finishing and edge trimming | Strong, durable seam construction |

| Stitch Type | Overlock stitch using multiple threads | Double-stitched seam with visible topstitching |

| Machine Required | Overlocker / Serger | Standard sewing machine |

| Durability | Moderate, prevents fraying | High, reinforced and durable |

| Seam Appearance | Neat, narrow edge finish | Flat, strong seam with visible stitching |

| Common Uses | Knitwear, stretch fabrics, quick finishing | Denim, workwear, heavy fabrics |

| Time Efficiency | Fast finishing method | More time-consuming |

Understanding Overlocking and Flat-Felling in Sewing

Overlocking creates a clean, professional edge by trimming excess fabric and enclosing seams with thread, preventing fraying on knit and woven fabrics. Flat-felling involves folding and stitching fabric edges flat for strong, durable seams commonly found in denim and activewear. Both techniques enhance garment longevity but differ in application, with overlocking offering speed and efficiency, while flat-felling provides reinforced, aesthetically flat seams.

Key Differences Between Overlocking and Flat-Felled Seams

Overlocking uses a serger machine to trim and enclose raw fabric edges with looped stitches, preventing fraying and providing stretch, ideal for knit fabrics. Flat-felled seams involve folding and stitching fabric edges flat, creating a strong, durable seam with double rows of stitching commonly used in denim and workwear. Overlocking offers speed and flexibility, while flat-felled seams emphasize strength and a clean, professional finish.

Advantages of Overlocking for Garment Construction

Overlocking offers superior seam finishing by preventing fabric fraying and providing a clean, professional edge, which enhances garment durability. Its multi-thread stitching capability creates flexible, stretchable seams ideal for knitwear and activewear. Overlocking also accelerates production efficiency by combining trimming and seam sealing in one step, reducing labor time significantly.

Benefits of Flat-Fell Seams in High-Quality Apparel

Flat-fell seams provide exceptional durability and a clean, professional finish, making them ideal for high-quality apparel that demands strength and longevity. These seams enclose raw edges completely, preventing fraying and enhancing garment longevity under frequent wear and washing. Unlike overlocking, flat-felling offers a polished aesthetic with reinforced stitching, contributing to the garment's premium appearance and structural integrity.

Overlocking Techniques for Efficiency in Mass Production

Overlocking techniques streamline mass production by combining seam finishing and edge trimming in a single operation, significantly reducing sewing time and minimizing fabric fraying. The use of specialized overlock machines with multiple threads enhances stitch strength and elasticity, ideal for high-speed garment assembly and durability. Compared to flat-felling, overlocking offers superior efficiency with easier automation, making it the preferred method in large-scale textile manufacturing.

Flat-Felling Methods for Durable and Clean Finishes

Flat-felling methods create highly durable and clean finishes by folding fabric edges under and stitching them flat, eliminating raw edges for enhanced strength and a polished look. This technique is commonly used in heavy-duty garments like jeans and workwear due to its superior seam reinforcement and neat appearance. Compared to overlocking, flat-felling provides a professional finish suitable for seams that require both aesthetic appeal and long-lasting durability.

Selecting the Right Seam Type for Your Sewing Business

Overlocking creates clean, durable edges by trimming and enclosing fabric edges simultaneously, ideal for knit fabrics and stretchy materials demanding flexibility and speed. Flat-felling seams offer utmost strength and a polished, professional finish, perfect for heavy fabrics like denim or workwear requiring reinforced durability and a neat appearance. Choosing between overlocking and flat-felling depends on fabric type, garment purpose, and desired seam strength, impacting production efficiency and product quality in your sewing business.

Cost-Effectiveness: Overlocking vs Flat-Felling

Overlocking offers greater cost-effectiveness by reducing sewing time and minimizing fabric waste, making it ideal for mass production. Flat-felling seams, while more durable and aesthetically pleasing, require more labor and materials, increasing overall costs. Manufacturers must balance the lower expenses of overlocking with the premium finish and strength provided by flat-felling based on project demands.

Common Industries Using Overlocking and Flat-Felling

Overlocking is predominantly used in the apparel and textile industries for finishing seams quickly and preventing fabric fraying, especially in mass-produced garments like t-shirts and activewear. Flat-felling seams are common in denim and outdoor gear manufacturing, providing durable and sturdy seams essential for heavy-duty clothing such as jeans and workwear. Both techniques serve distinct purposes in garment construction, with overlocking favored for flexible, lightweight fabrics and flat-felling applied in products requiring reinforced seam strength.

Tips for Seam Optimization in Professional Sewing

Overlocking provides a clean, stretch-friendly seam ideal for knit fabrics, while flat-felling offers exceptional durability and a smooth finish perfect for heavy-duty or decorative sewing projects. To optimize seams professionally, use appropriate stitch length and tension settings tailored to fabric type, and ensure precise seam allowance measurements for consistency. Applying edge trims or stabilizers before sewing enhances seam strength and prevents fraying, resulting in long-lasting, polished garments.

Overlocking vs Flat-Felling Infographic

bizdif.com

bizdif.com