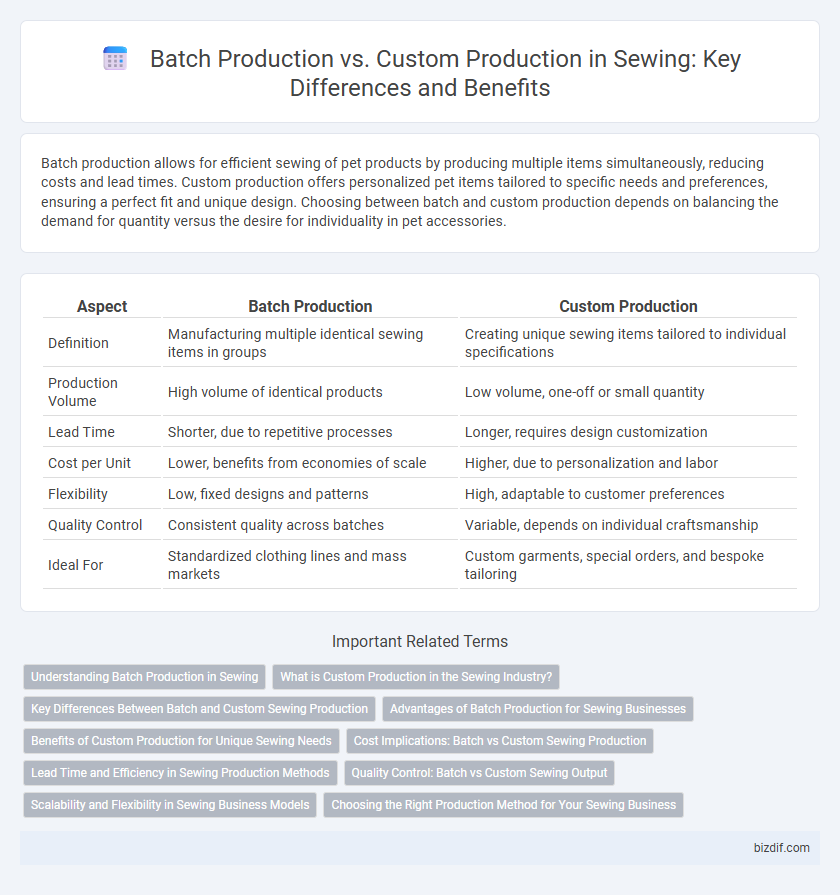

Batch production allows for efficient sewing of pet products by producing multiple items simultaneously, reducing costs and lead times. Custom production offers personalized pet items tailored to specific needs and preferences, ensuring a perfect fit and unique design. Choosing between batch and custom production depends on balancing the demand for quantity versus the desire for individuality in pet accessories.

Table of Comparison

| Aspect | Batch Production | Custom Production |

|---|---|---|

| Definition | Manufacturing multiple identical sewing items in groups | Creating unique sewing items tailored to individual specifications |

| Production Volume | High volume of identical products | Low volume, one-off or small quantity |

| Lead Time | Shorter, due to repetitive processes | Longer, requires design customization |

| Cost per Unit | Lower, benefits from economies of scale | Higher, due to personalization and labor |

| Flexibility | Low, fixed designs and patterns | High, adaptable to customer preferences |

| Quality Control | Consistent quality across batches | Variable, depends on individual craftsmanship |

| Ideal For | Standardized clothing lines and mass markets | Custom garments, special orders, and bespoke tailoring |

Understanding Batch Production in Sewing

Batch production in sewing involves creating a set quantity of garments or textile products in specific runs, allowing for consistent quality control and efficient use of materials and labor. This method reduces setup times and increases productivity by grouping similar tasks, making it ideal for moderate to large orders with standardized designs. Factories utilize batch production to balance flexibility with cost-effectiveness, enabling faster turnaround while maintaining customization options within each batch.

What is Custom Production in the Sewing Industry?

Custom production in the sewing industry involves creating garments tailored to specific client measurements and design preferences, ensuring unique, made-to-order pieces. This method emphasizes craftsmanship and attention to detail, often resulting in higher quality and personalization compared to mass-produced items. Custom production caters to niche markets such as bespoke fashion, costume design, and specialized uniforms.

Key Differences Between Batch and Custom Sewing Production

Batch sewing production involves creating multiple identical garments in a single run, maximizing efficiency and reducing per-unit costs through standardized processes. Custom sewing production focuses on individual garments tailored to specific customer measurements and preferences, emphasizing uniqueness and fit over speed and volume. Key differences include production scale, lead time, cost per item, and flexibility in design adjustments.

Advantages of Batch Production for Sewing Businesses

Batch production in sewing businesses enhances efficiency by allowing multiple garments to be produced simultaneously, reducing setup time and material waste. It enables streamlined inventory management and better cost control, leading to higher profit margins compared to custom production. Consistent quality and faster turnaround times are additional advantages that support scalable growth in garment manufacturing.

Benefits of Custom Production for Unique Sewing Needs

Custom production offers tailored solutions that precisely match unique sewing requirements, ensuring higher quality and superior fit compared to batch production. This approach reduces material waste by focusing on specific client preferences and measurements, enhancing overall sustainability. It also allows for greater design flexibility and faster adaptation to trends or individual style demands.

Cost Implications: Batch vs Custom Sewing Production

Batch sewing production reduces cost per unit by spreading fixed expenses across larger quantities, making it ideal for standardized garments. Custom sewing production incurs higher costs due to personalized labor, unique material sourcing, and longer production cycles tailored to individual specifications. Businesses must balance volume-driven cost efficiency against the flexibility and exclusivity offered by custom sewing services.

Lead Time and Efficiency in Sewing Production Methods

Batch production in sewing significantly reduces lead time by enabling simultaneous processing of multiple units, enhancing efficiency through standardized workflows and minimized changeovers. Custom production, while offering flexibility and tailored garments, typically incurs longer lead times due to individualized attention and more frequent retooling. Optimizing sewing methods involves balancing the speed of batch processing with the precision of custom production to meet specific market demands effectively.

Quality Control: Batch vs Custom Sewing Output

Batch production in sewing enables consistent quality control through standardized processes and repetitive inspections, which helps maintain uniformity across large quantities. Custom production focuses on individual garment quality, allowing for detailed adjustments and meticulous scrutiny to meet specific client requirements. Batch sewing typically excels in minimizing defects per unit, while custom production prioritizes craftsmanship and precision tailored to unique designs.

Scalability and Flexibility in Sewing Business Models

Batch production in sewing offers high scalability by enabling mass output through standardized processes, reducing costs per unit and meeting large order demands efficiently. Custom production emphasizes flexibility, allowing for tailored designs and adjustments that accommodate unique customer preferences but typically involves longer lead times and higher costs. Balancing scalability and flexibility is crucial for sewing businesses to optimize workflow, customer satisfaction, and market responsiveness.

Choosing the Right Production Method for Your Sewing Business

Batch production in sewing offers efficiency and cost savings for standardized garment lines, minimizing material waste and speeding up turnaround times. Custom production allows for personalized designs and fits, catering to niche markets with unique fabric choices and detailed craftsmanship. Assess your target market size, order volume, and design complexity to determine whether batch or custom production aligns best with your sewing business goals and operational capabilities.

Batch production vs custom production Infographic

bizdif.com

bizdif.com