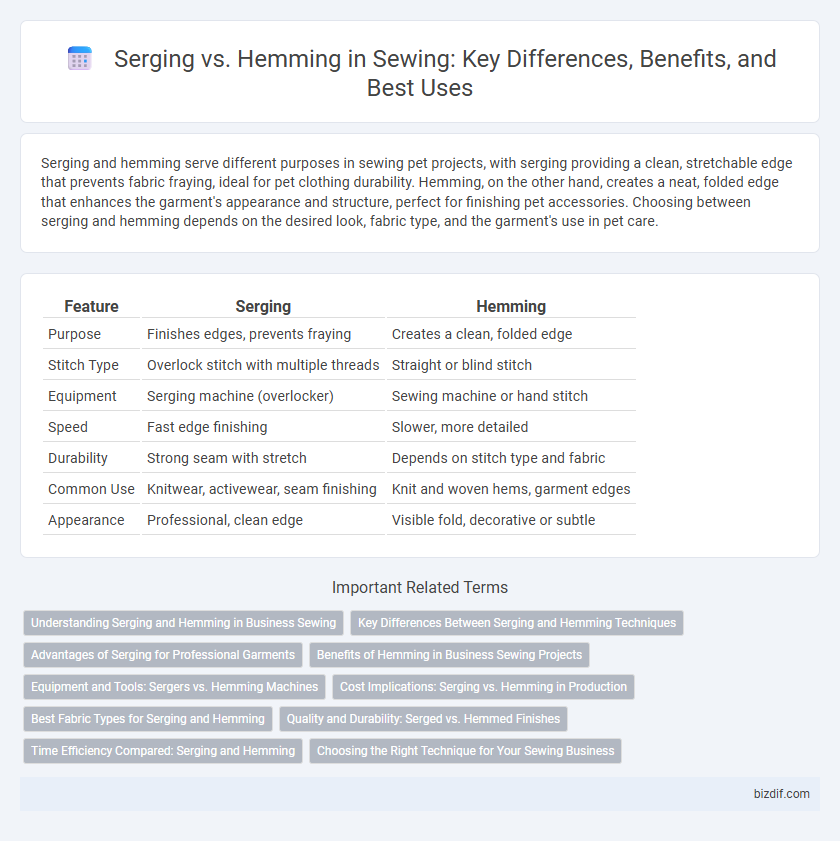

Serging and hemming serve different purposes in sewing pet projects, with serging providing a clean, stretchable edge that prevents fabric fraying, ideal for pet clothing durability. Hemming, on the other hand, creates a neat, folded edge that enhances the garment's appearance and structure, perfect for finishing pet accessories. Choosing between serging and hemming depends on the desired look, fabric type, and the garment's use in pet care.

Table of Comparison

| Feature | Serging | Hemming |

|---|---|---|

| Purpose | Finishes edges, prevents fraying | Creates a clean, folded edge |

| Stitch Type | Overlock stitch with multiple threads | Straight or blind stitch |

| Equipment | Serging machine (overlocker) | Sewing machine or hand stitch |

| Speed | Fast edge finishing | Slower, more detailed |

| Durability | Strong seam with stretch | Depends on stitch type and fabric |

| Common Use | Knitwear, activewear, seam finishing | Knit and woven hems, garment edges |

| Appearance | Professional, clean edge | Visible fold, decorative or subtle |

Understanding Serging and Hemming in Business Sewing

Serging creates durable, professional edges by trimming and enclosing raw fabric with overlock stitches, ideal for high-volume garment production in business sewing. Hemming involves folding fabric edges and stitching them to finish seams, enhancing garment durability and appearance in custom tailoring and small-scale sewing operations. Choosing between serging and hemming depends on fabric type, production speed, and desired garment finish in commercial sewing workflows.

Key Differences Between Serging and Hemming Techniques

Serging creates a finished edge by trimming and encasing fabric edges with thread to prevent fraying, using a serger machine with multiple threads for durability. Hemming folds fabric edges to create a clean, visible seam that secures fabric length, commonly sewn by hand or with a sewing machine. Key differences include serging's focus on edge finishing and fray prevention versus hemming's purpose of fabric length adjustment and clean edge presentation.

Advantages of Serging for Professional Garments

Serging offers superior edge finishing by preventing fabric fraying and enhancing garment durability, essential for professional-quality sewing. It creates clean, stretchy seams ideal for knit and delicate fabrics, ensuring a polished appearance and increased comfort. The versatile stitching options of sergers save time and improve production efficiency in garment manufacturing.

Benefits of Hemming in Business Sewing Projects

Hemming in business sewing projects provides a clean and professional finish that enhances the garment's durability and aesthetic appeal, leading to higher customer satisfaction. Compared to serging, hemming offers greater flexibility in fabric types and allows for precise control over the garment's edge, ensuring consistent quality. This technique reduces fraying and extends the product's lifespan, ultimately lowering return rates and increasing brand reputation.

Equipment and Tools: Sergers vs. Hemming Machines

Sergers utilize specialized overlock machines equipped with multiple threads and loopers to simultaneously trim, sew, and finish fabric edges, creating durable and professional seams ideal for stretch fabrics. Hemming machines, on the other hand, focus on folding fabric edges and stitching them in place using single or double needle configurations, offering precision for clean and flat hems on various materials. The choice between sergers and hemming machines depends on fabric type, desired finish, and production needs, with sergers excelling in edge finishing and hemming machines specializing in garment hems.

Cost Implications: Serging vs. Hemming in Production

Serging typically incurs higher initial equipment and thread costs but can reduce labor time by providing a faster, durable finish ideal for mass production. Hemming requires less specialized machinery and lower material expenses but often demands more manual labor, increasing overall production time and labor costs. Evaluating these factors, serging proves cost-effective for high-volume manufacturing, while hemming suits smaller-scale or budget-conscious projects.

Best Fabric Types for Serging and Hemming

Serging works best on knit fabrics, lightweight wovens, and stretch materials due to its ability to prevent fraying while maintaining fabric stretch. Hemming is ideal for medium to heavy-weight fabrics like denim, canvas, and upholstery fabric that require a durable, finished edge. Choosing the right fabric type ensures optimal seam strength and garment durability for sewing projects.

Quality and Durability: Serged vs. Hemmed Finishes

Serged finishes create strong, stable edges by encasing fabric raw edges with multiple threads, preventing fraying and enhancing durability in high-stress areas. Hemmed finishes fold fabric edges under and stitch them down, providing a clean and polished look but may be less resistant to wear over time. Quality-wise, serging delivers long-lasting strength ideal for active wear, while hemming offers aesthetic appeal suitable for garments with minimal strain.

Time Efficiency Compared: Serging and Hemming

Serging typically offers greater time efficiency compared to hemming due to its ability to simultaneously trim, sew, and finish fabric edges in a single pass. Hemming often requires multiple steps, including folding the fabric edge, pinning, and sewing, which increases overall sewing time. For projects requiring quick edge finishing, serging is the preferred method to reduce labor without sacrificing durability.

Choosing the Right Technique for Your Sewing Business

Serging creates clean, professional edges and prevents fabric fraying, making it ideal for stretch fabrics and high-volume garment production. Hemming offers a polished finish for hems and edges, suitable for delicate or structured fabrics where a subtle look is desired. Evaluating fabric type, production speed, and garment style helps determine whether serging or hemming optimizes quality and efficiency in your sewing business.

Serging vs hemming Infographic

bizdif.com

bizdif.com