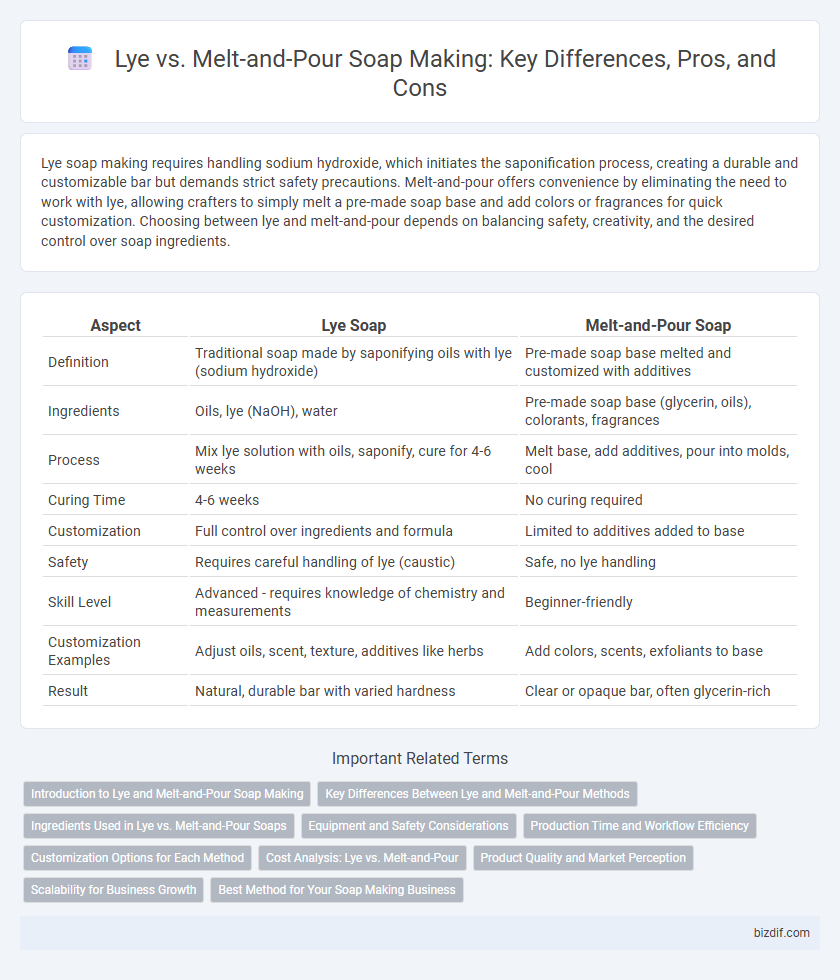

Lye soap making requires handling sodium hydroxide, which initiates the saponification process, creating a durable and customizable bar but demands strict safety precautions. Melt-and-pour offers convenience by eliminating the need to work with lye, allowing crafters to simply melt a pre-made soap base and add colors or fragrances for quick customization. Choosing between lye and melt-and-pour depends on balancing safety, creativity, and the desired control over soap ingredients.

Table of Comparison

| Aspect | Lye Soap | Melt-and-Pour Soap |

|---|---|---|

| Definition | Traditional soap made by saponifying oils with lye (sodium hydroxide) | Pre-made soap base melted and customized with additives |

| Ingredients | Oils, lye (NaOH), water | Pre-made soap base (glycerin, oils), colorants, fragrances |

| Process | Mix lye solution with oils, saponify, cure for 4-6 weeks | Melt base, add additives, pour into molds, cool |

| Curing Time | 4-6 weeks | No curing required |

| Customization | Full control over ingredients and formula | Limited to additives added to base |

| Safety | Requires careful handling of lye (caustic) | Safe, no lye handling |

| Skill Level | Advanced - requires knowledge of chemistry and measurements | Beginner-friendly |

| Customization Examples | Adjust oils, scent, texture, additives like herbs | Add colors, scents, exfoliants to base |

| Result | Natural, durable bar with varied hardness | Clear or opaque bar, often glycerin-rich |

Introduction to Lye and Melt-and-Pour Soap Making

Lye soap making involves combining sodium hydroxide with oils or fats to initiate saponification, resulting in a customizable and durable soap bar. Melt-and-pour soap making uses pre-made glycerin soap bases that melt easily, allowing for quick embedding of colors, scents, and additives without handling caustic lye. Lye methods provide greater control over ingredients and soap properties, while melt-and-pour offers convenience and safety for beginners.

Key Differences Between Lye and Melt-and-Pour Methods

Lye soap making involves a chemical reaction called saponification where lye (sodium hydroxide) reacts with oils, requiring precise measurements and safety precautions due to its caustic nature. Melt-and-pour soap uses a pre-made soap base that has already undergone saponification, allowing crafters to simply melt the base and add additives without handling lye directly. Lye soap offers more customization and control over ingredients and properties, while melt-and-pour prioritizes convenience and speed in the soap making process.

Ingredients Used in Lye vs. Melt-and-Pour Soaps

Lye soap uses a chemical reaction between sodium hydroxide (lye) and oils or fats, creating a saponification process that forms durable soap bars. Melt-and-pour soap bases contain pre-saponified glycerin combined with additives like colorants, fragrances, and moisturizers, simplifying customization without handling lye. The choice of ingredients in lye soap requires precise measurement and safety precautions, while melt-and-pour ingredients cater to convenience and creative flexibility.

Equipment and Safety Considerations

Lye soap making requires specialized equipment such as heat-resistant containers, accurate digital scales, and protective gear including gloves, goggles, and long sleeves due to the caustic nature of sodium hydroxide. Melt-and-pour soap making demands minimal safety equipment, often limited to non-toxic, pre-made soap bases melted in microwave-safe containers, eliminating hazardous chemical handling. Prioritizing proper ventilation and workspace cleanliness is critical in both methods to ensure safe soap crafting environments.

Production Time and Workflow Efficiency

Lye soap making involves a longer production time due to the saponification process requiring days to cure and harden, which can slow down workflow efficiency. In contrast, melt-and-pour soap allows for immediate use after cooling, significantly reducing production time and streamlining the workflow for faster batch turnaround. Manufacturers aiming for rapid project completion often prefer melt-and-pour for its ease of use and minimal curing requirements.

Customization Options for Each Method

Lye soap making offers extensive customization options by allowing precise control over ingredients such as oils, lye concentration, and additives, enabling unique textures, scents, and healing properties tailored to personal preferences. Melt-and-pour soap simplifies customization by using pre-made soap bases, making it easy to add colors, fragrances, and exfoliants without handling hazardous chemicals. While lye soap demands careful measurement and curing time for desired results, melt-and-pour provides quick, user-friendly customization ideal for beginners or small-batch crafting.

Cost Analysis: Lye vs. Melt-and-Pour

Lye soap making involves purchasing raw ingredients like sodium hydroxide and oils, often resulting in lower material costs but requires safety equipment and time-intensive processes, which can increase overall expenses. Melt-and-pour soap bases have higher upfront costs per pound but reduce risk, equipment needs, and production time, making them cost-efficient for beginners or small batches. Evaluating costs depends on batch size, safety considerations, and the desired level of customization in soap formulations.

Product Quality and Market Perception

Lye-based soap offers superior glycerin content, resulting in a moisturizing and long-lasting bar that appeals to discerning consumers seeking natural ingredients. Melt-and-pour soap prioritizes convenience and vibrant aesthetics but often contains synthetic additives that can diminish perceived purity and product quality. Market perception favors lye soap for its artisanal craftsmanship and skin benefits, positioning it as a premium choice in the niche soap market.

Scalability for Business Growth

Lye soap making offers greater scalability for business growth through customizable formulations and bulk ingredient sourcing, enabling tailored products that meet diverse market demands. Melt-and-pour soap is limited by pre-made bases, restricting product differentiation and volume expansion. Entrepreneurs aiming for scalable production and brand differentiation typically prefer lye soap methods due to their flexibility and cost efficiency.

Best Method for Your Soap Making Business

Choosing between lye and melt-and-pour soap making depends on your business goals and skill level. Lye allows for customization and control over ingredients, making it ideal for artisanal, natural soap brands that prioritize quality and uniqueness. Melt-and-pour offers convenience and safety, perfect for small-scale producers or those looking to quickly test new designs without the hazards of handling caustic soda.

Lye vs Melt-and-Pour Infographic

bizdif.com

bizdif.com