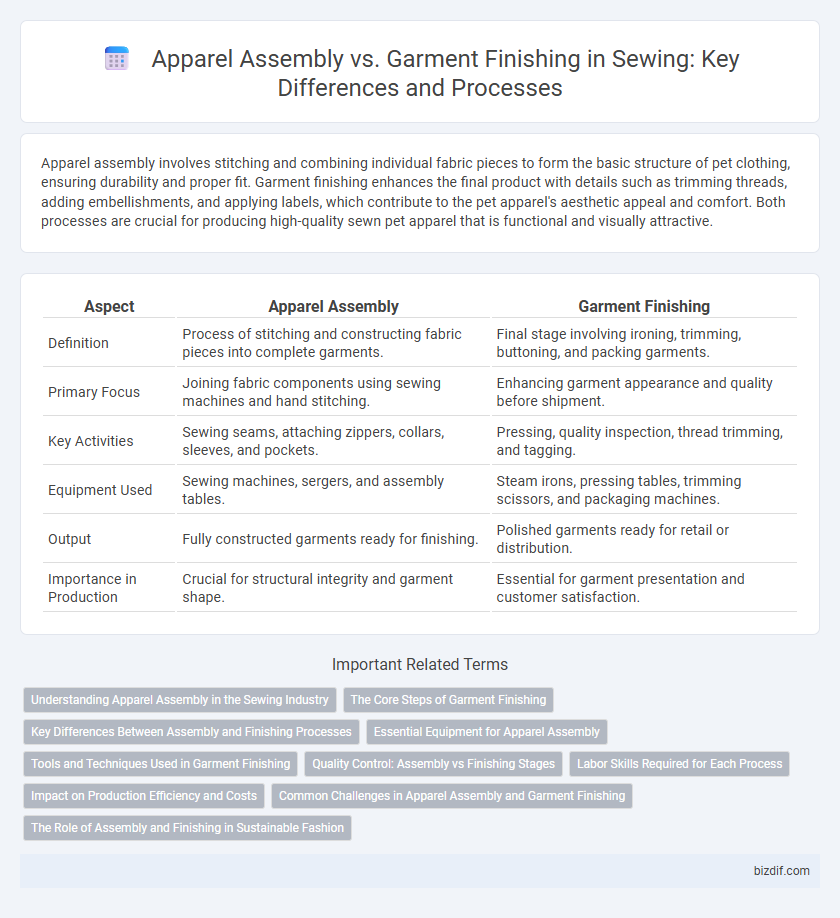

Apparel assembly involves stitching and combining individual fabric pieces to form the basic structure of pet clothing, ensuring durability and proper fit. Garment finishing enhances the final product with details such as trimming threads, adding embellishments, and applying labels, which contribute to the pet apparel's aesthetic appeal and comfort. Both processes are crucial for producing high-quality sewn pet apparel that is functional and visually attractive.

Table of Comparison

| Aspect | Apparel Assembly | Garment Finishing |

|---|---|---|

| Definition | Process of stitching and constructing fabric pieces into complete garments. | Final stage involving ironing, trimming, buttoning, and packing garments. |

| Primary Focus | Joining fabric components using sewing machines and hand stitching. | Enhancing garment appearance and quality before shipment. |

| Key Activities | Sewing seams, attaching zippers, collars, sleeves, and pockets. | Pressing, quality inspection, thread trimming, and tagging. |

| Equipment Used | Sewing machines, sergers, and assembly tables. | Steam irons, pressing tables, trimming scissors, and packaging machines. |

| Output | Fully constructed garments ready for finishing. | Polished garments ready for retail or distribution. |

| Importance in Production | Crucial for structural integrity and garment shape. | Essential for garment presentation and customer satisfaction. |

Understanding Apparel Assembly in the Sewing Industry

Apparel assembly in the sewing industry involves stitching together various fabric components to create a complete garment, emphasizing precision and alignment to ensure durability and fit. This phase requires specialized machinery and skilled labor to handle multiple fabric types and intricate patterns effectively. Unlike garment finishing, which focuses on final touches like pressing, trimming, and quality inspection, apparel assembly is foundational for constructing the garment's basic structure.

The Core Steps of Garment Finishing

Garment finishing involves core steps such as trimming excess threads, pressing seams to ensure a polished look, and attaching final labels or tags to the apparel. Unlike apparel assembly, which focuses on stitching fabric pieces together, finishing enhances the garment's overall quality and appearance. Essential finishing techniques also include checking for defects and applying treatments like fabric softeners or anti-wrinkle sprays.

Key Differences Between Assembly and Finishing Processes

Apparel assembly involves the initial stages of garment construction, including cutting, stitching, and joining fabric pieces to create the basic form, while garment finishing focuses on enhancing and refining the product with processes like pressing, trimming, button attachment, and quality inspection. Assembly requires precise alignment and seam strength to ensure durability, whereas finishing emphasizes aesthetic appeal and functional detailing to meet design specifications. The primary difference lies in assembly building the garment's structure, whereas finishing completes its appearance and usability.

Essential Equipment for Apparel Assembly

Essential equipment for apparel assembly includes industrial sewing machines, overlockers, buttonhole machines, and automated cutting tables that ensure precision and efficiency. These machines streamline the stitching, seaming, and stitching reinforcement processes fundamental to garment construction. Unlike garment finishing, which utilizes pressing machines and embroidery equipment, apparel assembly demands robust and versatile machinery tailored for high-volume production and diverse fabric handling.

Tools and Techniques Used in Garment Finishing

Garment finishing employs specialized tools such as pressing machines, steamers, and trimming devices to enhance the garment's appearance and fit. Techniques include precise seam pressing, edge trimming, adding labels, and applying embellishments to ensure quality and durability. Advanced finishing methods like ultrasonic welding and heat setting improve fabric stability and achieve a polished, professional look.

Quality Control: Assembly vs Finishing Stages

Quality control in apparel assembly focuses on verifying stitch integrity, seam alignment, and component accuracy to ensure the garment meets design specifications. During garment finishing, quality control shifts to surface inspection, checking for defects such as stains, loose threads, and proper labeling, ensuring the final product's visual and functional standards. Both stages are critical, with assembly emphasizing structural quality while finishing prioritizes appearance and overall presentation.

Labor Skills Required for Each Process

Apparel assembly demands advanced sewing skills, including pattern alignment, precise stitching, and machine operation expertise to ensure structural integrity of garments. Garment finishing requires specialized labor proficiency in techniques such as pressing, trimming, and quality inspection to enhance the appearance and final fit. Skilled workers in assembly focus on construction accuracy, while finishing labor emphasizes detail-oriented tasks that prepare the garment for market readiness.

Impact on Production Efficiency and Costs

Apparel assembly streamlines production by focusing on the precise stitching and joining of fabric pieces, directly affecting labor time and material usage. Garment finishing enhances product quality through processes such as trimming, pressing, and quality inspection, which influence the final production speed and reduce defect rates. Efficient coordination between assembly and finishing stages lowers overall manufacturing costs by minimizing rework and optimizing workflow continuity.

Common Challenges in Apparel Assembly and Garment Finishing

Common challenges in apparel assembly include maintaining consistent stitching quality, managing fabric distortion, and aligning multiple fabric layers accurately. In garment finishing, issues often arise with color matching, securing fasteners properly, and ensuring wrinkle-free pressing, which directly impact the final product's appearance. Both stages demand precise quality control to minimize defects and reduce production delays in the apparel manufacturing process.

The Role of Assembly and Finishing in Sustainable Fashion

Apparel assembly involves constructing garments through stitching, cutting, and folding, ensuring precise fit and durability, which directly impacts sustainability by reducing material waste and enhancing product longevity. Garment finishing includes processes such as pressing, trimming, and labeling, which improve the garment's appearance and functionality, contributing to sustainable fashion by extending wearability and enabling easier recycling. Integrating efficient assembly and finishing techniques optimizes resource use and minimizes environmental footprint in the fashion supply chain.

Apparel Assembly vs Garment Finishing Infographic

bizdif.com

bizdif.com