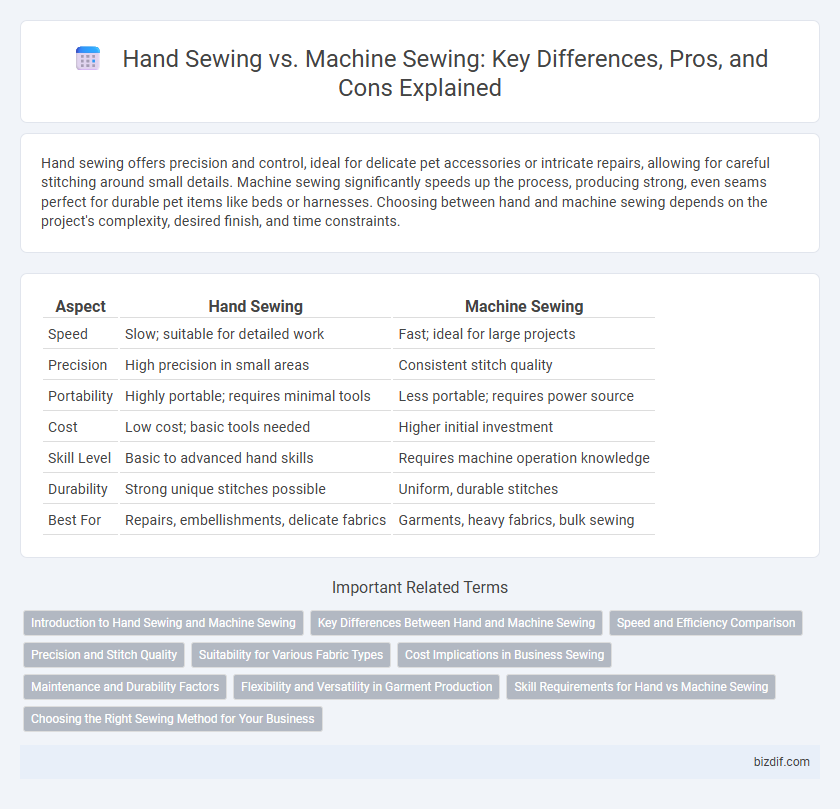

Hand sewing offers precision and control, ideal for delicate pet accessories or intricate repairs, allowing for careful stitching around small details. Machine sewing significantly speeds up the process, producing strong, even seams perfect for durable pet items like beds or harnesses. Choosing between hand and machine sewing depends on the project's complexity, desired finish, and time constraints.

Table of Comparison

| Aspect | Hand Sewing | Machine Sewing |

|---|---|---|

| Speed | Slow; suitable for detailed work | Fast; ideal for large projects |

| Precision | High precision in small areas | Consistent stitch quality |

| Portability | Highly portable; requires minimal tools | Less portable; requires power source |

| Cost | Low cost; basic tools needed | Higher initial investment |

| Skill Level | Basic to advanced hand skills | Requires machine operation knowledge |

| Durability | Strong unique stitches possible | Uniform, durable stitches |

| Best For | Repairs, embellishments, delicate fabrics | Garments, heavy fabrics, bulk sewing |

Introduction to Hand Sewing and Machine Sewing

Hand sewing involves stitching fabric manually using needles and thread, offering greater precision for delicate tasks, intricate designs, and small repairs. Machine sewing utilizes a sewing machine, which enables faster, consistent stitching ideal for large projects, durable seams, and high-volume production. Understanding the applications and techniques of both hand and machine sewing is essential for optimizing textile crafting and garment construction.

Key Differences Between Hand and Machine Sewing

Hand sewing offers precision for intricate details and small repairs, utilizing a needle and thread manipulated manually for control over each stitch. Machine sewing enables faster stitch production, consistent tension, and uniform seams, ideal for handling larger fabrics and repetitive tasks with a sewing machine. The key differences lie in speed, stitch uniformity, and suitability for complex versus bulk projects.

Speed and Efficiency Comparison

Machine sewing offers significantly faster stitching speeds, producing hundreds of stitches per minute compared to the few stitches achievable by hand sewing within the same timeframe. Efficiency in machine sewing is highlighted by consistent stitch quality, reduced manual effort, and capability to handle large-scale projects quickly. Hand sewing remains essential for intricate details, repairs, and areas where precision is paramount, though it requires substantially more time and labor.

Precision and Stitch Quality

Hand sewing allows for intricate control and precision in delicate or detailed work, producing unique, customizable stitch patterns that suit small or complex areas. Machine sewing offers consistent, even stitches with superior strength and durability, ideal for handling large fabric pieces and repetitive stitching tasks. Choosing between hand and machine sewing depends on the required stitch quality, fabric type, and project complexity.

Suitability for Various Fabric Types

Hand sewing excels in handling delicate fabrics like silk, chiffon, and lace due to its precision and control, minimizing damage and puckering. Machine sewing is ideal for sturdier fabrics such as denim, canvas, and upholstery materials, providing speed and strong, even stitches suitable for heavy-duty projects. Both methods offer unique advantages depending on fabric thickness, texture, and the desired stitch type, ensuring optimal results across diverse textile applications.

Cost Implications in Business Sewing

Hand sewing requires minimal initial investment, with basic tools such as needles, thread, and scissors being relatively inexpensive, making it cost-efficient for small-scale or custom projects. Machine sewing involves higher upfront costs, including purchasing and maintaining sewing machines, but significantly increases productivity and consistency, leading to lower labor costs per unit in large-scale production. Businesses balancing quality and volume often weigh the lower operational costs of hand sewing against the efficiency and long-term savings offered by industrial sewing machines.

Maintenance and Durability Factors

Hand sewing requires minimal maintenance, primarily involving regular needle replacement and thread care, leading to greater control over stitch quality and durability. Machine sewing demands consistent machine servicing, such as oiling, cleaning lint buildup, and timely part replacements to ensure optimal performance and stitch strength. Durability factors favor machine sewing for heavy fabrics and large projects due to uniform stitches, while hand sewing excels in precision repairs and delicate materials requiring nuanced stitch tension.

Flexibility and Versatility in Garment Production

Hand sewing offers unparalleled flexibility and precision, allowing for intricate detailing and customization in garment production that machines often cannot replicate. Machine sewing excels in versatility through speed and consistency, making it ideal for mass production and durable seams. Combining both techniques enhances overall garment quality by leveraging the strengths of hand sewing's adaptability and machine sewing's efficiency.

Skill Requirements for Hand vs Machine Sewing

Hand sewing demands precise manual dexterity, patience, and mastery of various stitch techniques, making it ideal for intricate or delicate projects. Machine sewing requires proficiency in operating sewing machines, understanding different stitch settings, and troubleshooting mechanical issues. Both skills necessitate practice, but hand sewing emphasizes fine motor control while machine sewing highlights technical knowledge and speed.

Choosing the Right Sewing Method for Your Business

Hand sewing offers precision and control for delicate or intricate work, ideal for bespoke tailoring and detailed embellishments in fashion businesses. Machine sewing enhances speed and consistency, making it suitable for high-volume production and commercial garment manufacturing. Selecting the right sewing method depends on your business scale, fabric type, and quality requirements to optimize efficiency and product value.

Hand Sewing vs Machine Sewing Infographic

bizdif.com

bizdif.com