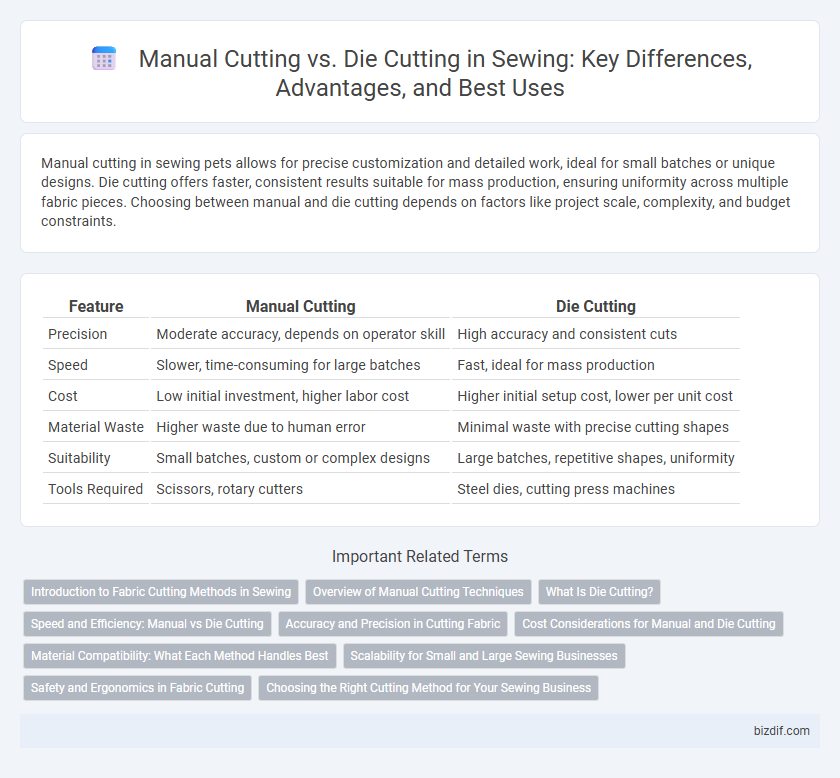

Manual cutting in sewing pets allows for precise customization and detailed work, ideal for small batches or unique designs. Die cutting offers faster, consistent results suitable for mass production, ensuring uniformity across multiple fabric pieces. Choosing between manual and die cutting depends on factors like project scale, complexity, and budget constraints.

Table of Comparison

| Feature | Manual Cutting | Die Cutting |

|---|---|---|

| Precision | Moderate accuracy, depends on operator skill | High accuracy and consistent cuts |

| Speed | Slower, time-consuming for large batches | Fast, ideal for mass production |

| Cost | Low initial investment, higher labor cost | Higher initial setup cost, lower per unit cost |

| Material Waste | Higher waste due to human error | Minimal waste with precise cutting shapes |

| Suitability | Small batches, custom or complex designs | Large batches, repetitive shapes, uniformity |

| Tools Required | Scissors, rotary cutters | Steel dies, cutting press machines |

Introduction to Fabric Cutting Methods in Sewing

Manual cutting in sewing involves using scissors or rotary cutters to precisely shape fabric pieces by hand, offering flexibility for intricate designs and small-scale projects. Die cutting employs specialized machines and metal dies to produce uniform shapes rapidly, enhancing efficiency in mass production and repetitive patterns. Both methods are essential in fabric cutting, with manual cutting suited for custom, detailed work, and die cutting ideal for consistency and speed in garment manufacturing.

Overview of Manual Cutting Techniques

Manual cutting techniques in sewing involve using hand tools such as scissors, rotary cutters, and fabric knives to precisely shape fabric pieces according to pattern templates. This method allows for greater control and flexibility, especially useful for small-scale or intricate projects requiring detailed craftsmanship. Manual cutting is preferred for bespoke tailoring and custom designs where accuracy and attention to fabric grain are critical.

What Is Die Cutting?

Die cutting in sewing involves using a specialized machine equipped with sharp steel blades shaped into specific patterns to precisely cut fabric pieces. This method ensures consistent, accurate shapes ideal for mass production, reducing material waste and saving time compared to manual cutting. The precise die-cut fabric pieces streamline the assembly process, enhancing efficiency and product uniformity in garment manufacturing.

Speed and Efficiency: Manual vs Die Cutting

Manual cutting requires skilled labor and is significantly slower, taking more time to achieve precise fabric shapes, which limits productivity in large-scale sewing projects. Die cutting offers rapid and consistent cuts, dramatically increasing efficiency by processing multiple layers of fabric simultaneously, reducing waste and labor costs. High-volume manufacturers favor die cutting to maintain speed and uniformity, essential for meeting tight production deadlines.

Accuracy and Precision in Cutting Fabric

Manual cutting in sewing offers flexibility but often lacks the accuracy and precision required for intricate fabric patterns, leading to inconsistencies in garment fit. Die cutting uses sharp, custom-designed steel blades to ensure exact, repeatable cuts with minimal fabric distortion, enhancing overall production quality. High-precision die cutting significantly reduces material waste and improves assembly efficiency in mass garment manufacturing.

Cost Considerations for Manual and Die Cutting

Manual cutting offers lower upfront costs as it requires minimal equipment investment, making it ideal for small-scale or custom sewing projects. Die cutting involves higher initial expenses due to die creation, but reduces labor costs and increases efficiency for large production runs, ultimately lowering per-unit cost. Evaluating production volume and budget constraints is essential to determine the most cost-effective cutting method for sewing applications.

Material Compatibility: What Each Method Handles Best

Manual cutting excels with thick, multi-layered fabrics like denim or leather, offering precise control for intricate shapes and custom adjustments. Die cutting is ideal for lightweight or medium-weight materials such as cotton, felt, and synthetic blends, enabling efficient mass production with consistent shapes. Both techniques complement different textile compositions, ensuring optimal material handling based on fabric thickness, texture, and production volume.

Scalability for Small and Large Sewing Businesses

Manual cutting offers flexibility and precision for small sewing businesses, enabling low-volume production with minimal upfront investment. Die cutting scales effectively for large sewing operations, delivering high-speed, consistent cuts that optimize efficiency and reduce labor costs. Choosing between manual and die cutting depends on production volume, budget, and the need for scalability in sewing manufacturing processes.

Safety and Ergonomics in Fabric Cutting

Manual cutting in fabric handling involves the use of handheld scissors or rotary cutters, offering precise control but posing risks like repetitive strain injuries and accidental cuts due to prolonged use. Die cutting uses a press machine with shaped blades to cut multiple fabric layers simultaneously, enhancing consistency and significantly reducing repetitive motion strain for operators. Ergonomically, die cutting machines often feature adjustable heights and safety guards, minimizing physical fatigue and workplace accidents compared to manual methods.

Choosing the Right Cutting Method for Your Sewing Business

Selecting the optimal cutting method for your sewing business depends on production volume, fabric type, and precision requirements. Manual cutting offers flexibility and cost-effectiveness for small-scale, custom projects, while die cutting provides uniformity and speed ideal for large-scale manufacturing. Understanding the trade-offs between these techniques ensures efficiency, reduces fabric waste, and maintains product quality.

Manual cutting vs Die cutting Infographic

bizdif.com

bizdif.com