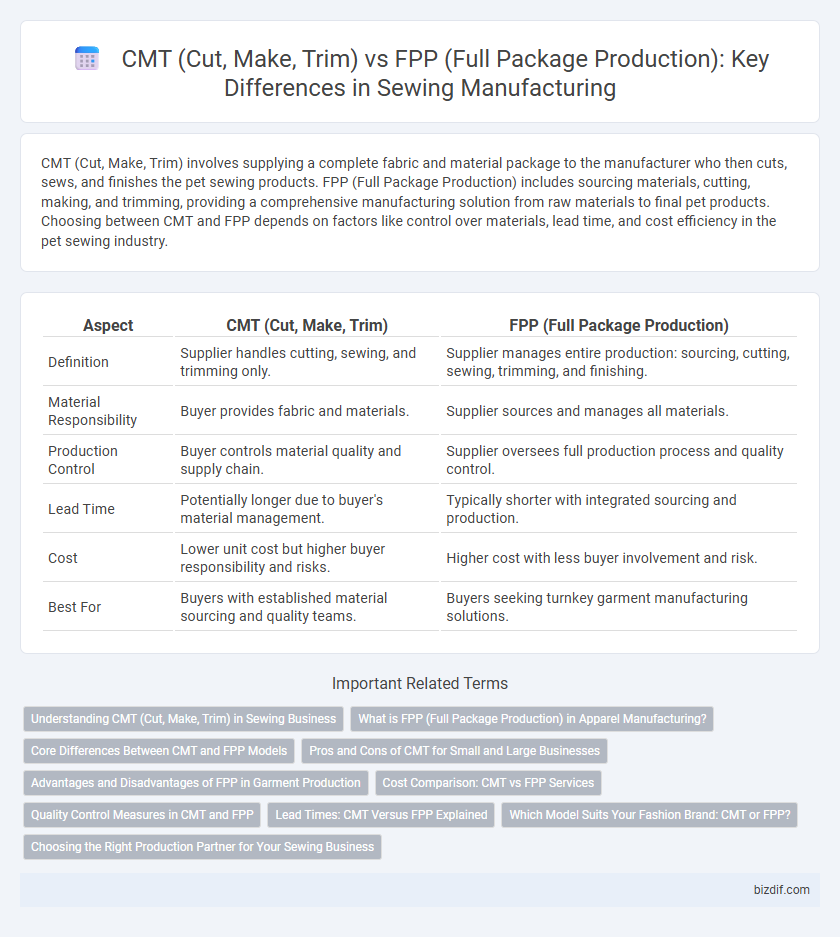

CMT (Cut, Make, Trim) involves supplying a complete fabric and material package to the manufacturer who then cuts, sews, and finishes the pet sewing products. FPP (Full Package Production) includes sourcing materials, cutting, making, and trimming, providing a comprehensive manufacturing solution from raw materials to final pet products. Choosing between CMT and FPP depends on factors like control over materials, lead time, and cost efficiency in the pet sewing industry.

Table of Comparison

| Aspect | CMT (Cut, Make, Trim) | FPP (Full Package Production) |

|---|---|---|

| Definition | Supplier handles cutting, sewing, and trimming only. | Supplier manages entire production: sourcing, cutting, sewing, trimming, and finishing. |

| Material Responsibility | Buyer provides fabric and materials. | Supplier sources and manages all materials. |

| Production Control | Buyer controls material quality and supply chain. | Supplier oversees full production process and quality control. |

| Lead Time | Potentially longer due to buyer's material management. | Typically shorter with integrated sourcing and production. |

| Cost | Lower unit cost but higher buyer responsibility and risks. | Higher cost with less buyer involvement and risk. |

| Best For | Buyers with established material sourcing and quality teams. | Buyers seeking turnkey garment manufacturing solutions. |

Understanding CMT (Cut, Make, Trim) in Sewing Business

CMT (Cut, Make, Trim) in the sewing business refers to a manufacturing process where the contractor handles cutting fabric, stitching garments, and adding trims based on materials supplied by the client. This method allows brands to maintain control over fabric sourcing and design while outsourcing labor-intensive assembly tasks to specialized production units. Understanding CMT is crucial for optimizing cost efficiency, lead time, and quality control in apparel manufacturing.

What is FPP (Full Package Production) in Apparel Manufacturing?

Full Package Production (FPP) in apparel manufacturing refers to a service model where the manufacturer handles the entire production process, including sourcing materials, cutting, sewing, finishing, and packing the garments. This turnkey solution allows brands to focus on design and marketing while the factory manages procurement, quality control, and logistics. FPP offers efficiency and consistency by integrating all steps from raw fabric to finished product under one management system.

Core Differences Between CMT and FPP Models

CMT (Cut, Make, Trim) focuses solely on garment assembly where manufacturers receive pre-cut fabric and designs, emphasizing production efficiency and cost control. FPP (Full Package Production) entails comprehensive services including sourcing raw materials, fabric procurement, pattern making, cutting, sewing, and finishing, ensuring end-to-end garment delivery. The core difference lies in FPP's full supply chain management versus CMT's limited role confined to garment construction.

Pros and Cons of CMT for Small and Large Businesses

CMT (Cut, Make, Trim) offers small businesses greater control over material sourcing and cost management, allowing flexibility in quality and design adjustments. For large businesses, CMT can reduce dependency on manufacturers but demands robust supply chain coordination and higher internal management resources. However, CMT's reliance on external fabric procurement may increase lead times and risks, contrasting with the streamlined efficiency of Full Package Production (FPP).

Advantages and Disadvantages of FPP in Garment Production

Full Package Production (FPP) offers streamlined garment production by handling all processes from sourcing materials to final assembly, reducing coordination efforts for brands. This method enhances quality control and accelerates time-to-market but requires higher initial investment and less flexibility in design changes during production. Brands may face dependency risks on suppliers' capabilities and potential supply chain complexities with FPP compared to Cut, Make, Trim (CMT) models.

Cost Comparison: CMT vs FPP Services

CMT (Cut, Make, Trim) services typically offer lower upfront costs as they focus solely on garment construction, requiring the buyer to supply fabrics and trims, which reduces overall production expenses. FPP (Full Package Production) services include sourcing materials, manufacturing, and often quality control, leading to higher costs but greater convenience and reduced logistic complexity. Choosing between CMT and FPP depends on budget constraints, control over sourcing, and desired manufacturing responsibility, with FPP generally incurring 20-30% higher costs due to the comprehensive service scope.

Quality Control Measures in CMT and FPP

CMT (Cut, Make, Trim) involves the client providing all materials, requiring stringent quality control on fabric inspection and cutting accuracy to prevent defects during sewing and trimming. FPP (Full Package Production) demands comprehensive quality control across sourcing, fabric testing, production processes, and final garment inspection to ensure consistent standards from raw materials to finished products. Effective quality control measures in both CMT and FPP reduce material waste, minimize production errors, and enhance overall garment durability and appearance.

Lead Times: CMT Versus FPP Explained

Lead times for CMT (Cut, Make, Trim) typically range from 2 to 4 weeks as factories handle only specific aspects of garment production. FPP (Full Package Production) requires longer lead times, often 4 to 8 weeks, due to comprehensive management of sourcing, cutting, sewing, and finishing within one supplier. Understanding these differences in lead times helps brands optimize production schedules and meet market demands efficiently.

Which Model Suits Your Fashion Brand: CMT or FPP?

Choosing between CMT (Cut, Make, Trim) and FPP (Full Package Production) depends on your fashion brand's production needs and resources. CMT suits brands with established fabric sourcing and design control, offering flexibility in handling specific manufacturing stages. FPP is ideal for brands seeking a turnkey solution, as it manages everything from material sourcing to final garment production, streamlining operations and reducing management complexity.

Choosing the Right Production Partner for Your Sewing Business

Selecting the right production partner for your sewing business depends on your control preferences and resource availability; CMT (Cut, Make, Trim) allows for greater oversight of fabric sourcing and design management, ideal for brands with in-house expertise. FPP (Full Package Production) offers a turnkey solution encompassing material procurement, manufacturing, and finishing, suited for businesses seeking efficiency and scalability without managing separate supply chain components. Evaluating factors like cost, lead time, and quality consistency is crucial when deciding between CMT and FPP to align production strategies with your brand's operational goals.

CMT (Cut, Make, Trim) vs FPP (Full Package Production) Infographic

bizdif.com

bizdif.com