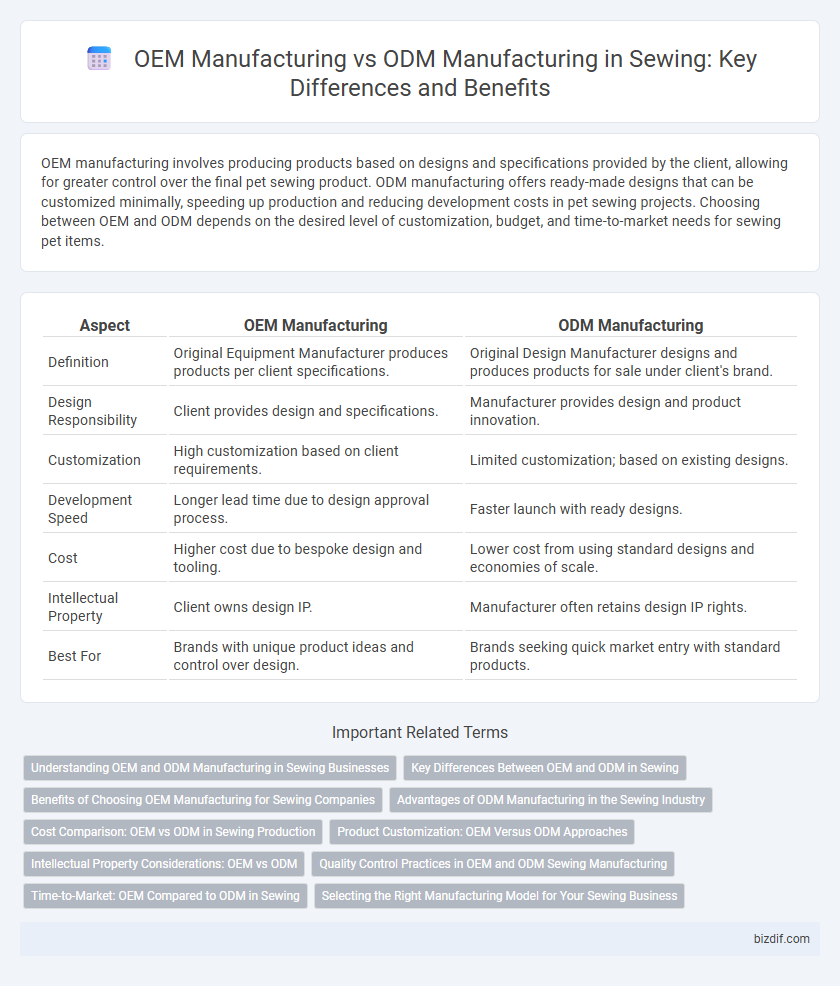

OEM manufacturing involves producing products based on designs and specifications provided by the client, allowing for greater control over the final pet sewing product. ODM manufacturing offers ready-made designs that can be customized minimally, speeding up production and reducing development costs in pet sewing projects. Choosing between OEM and ODM depends on the desired level of customization, budget, and time-to-market needs for sewing pet items.

Table of Comparison

| Aspect | OEM Manufacturing | ODM Manufacturing |

|---|---|---|

| Definition | Original Equipment Manufacturer produces products per client specifications. | Original Design Manufacturer designs and produces products for sale under client's brand. |

| Design Responsibility | Client provides design and specifications. | Manufacturer provides design and product innovation. |

| Customization | High customization based on client requirements. | Limited customization; based on existing designs. |

| Development Speed | Longer lead time due to design approval process. | Faster launch with ready designs. |

| Cost | Higher cost due to bespoke design and tooling. | Lower cost from using standard designs and economies of scale. |

| Intellectual Property | Client owns design IP. | Manufacturer often retains design IP rights. |

| Best For | Brands with unique product ideas and control over design. | Brands seeking quick market entry with standard products. |

Understanding OEM and ODM Manufacturing in Sewing Businesses

OEM manufacturing in sewing businesses involves producing garments strictly based on the client's design specifications, allowing brands to outsource production without investing in design development. ODM manufacturing provides sewing companies with ready-made designs and patterns, enabling clients to purchase finished products or customize existing styles with minimal input. Understanding the differences helps businesses choose between full customization with OEM or streamlined production and design support through ODM.

Key Differences Between OEM and ODM in Sewing

OEM manufacturing in sewing involves producing garments strictly based on the client's design specifications, ensuring precise replication and adherence to provided patterns and materials. ODM manufacturing includes the creation of original designs and product development by the manufacturer, offering clients ready-to-market apparel with unique styles and innovative features. Key differences lie in design ownership and creativity, where OEM focuses on manufacturing execution and ODM emphasizes product design and innovation within the sewing industry.

Benefits of Choosing OEM Manufacturing for Sewing Companies

OEM manufacturing in sewing allows companies to maintain control over product specifications and branding, ensuring a customized final product that aligns with their market identity. This approach enables cost-efficient scalability by leveraging the manufacturer's established production capabilities without the need for extensive in-house resources. Sewing companies benefit from reduced time-to-market and consistent quality, which are critical for meeting customer demands and sustaining competitive advantage.

Advantages of ODM Manufacturing in the Sewing Industry

ODM manufacturing in the sewing industry offers streamlined production processes by providing ready-to-market designs, reducing development time and costs for brands. It enables companies to leverage the manufacturer's expertise in design innovation and quality control, resulting in high-quality, trend-responsive products. Moreover, ODM partners facilitate faster product launches and scalable production, enhancing competitiveness in dynamic fashion markets.

Cost Comparison: OEM vs ODM in Sewing Production

OEM manufacturing in sewing production typically offers lower upfront costs since it involves producing designs provided by the client, reducing design and development expenses. ODM manufacturing incurs higher initial costs due to the inclusion of product design and innovation services but can lead to cost savings in the long term through streamlined production and reduced need for client-side development. Choosing between OEM and ODM depends on budget priorities, with OEM suited for cost-sensitive projects and ODM beneficial for brands seeking unique product differentiation without investing heavily in design resources.

Product Customization: OEM Versus ODM Approaches

OEM manufacturing offers extensive product customization by allowing brands to design and specify exact sewing materials, patterns, and construction methods, ensuring unique final products aligned with their brand identity. ODM manufacturing provides pre-designed sewing products that can be modified within certain limits, enabling quicker production while maintaining some level of customization in fabric choice or color. Brands seeking full control over design details typically prefer OEM, whereas ODM suits those prioritizing rapid market entry with flexible but standardized customization.

Intellectual Property Considerations: OEM vs ODM

OEM manufacturing maintains the client's intellectual property rights, as the production strictly follows the client's existing designs and specifications. ODM manufacturing often involves the supplier creating original designs, which can lead to shared or supplier-held intellectual property ownership. Understanding the differences in IP control is crucial for businesses to protect their proprietary designs and innovation when choosing between OEM and ODM sewing manufacturing.

Quality Control Practices in OEM and ODM Sewing Manufacturing

OEM sewing manufacturing employs strict quality control practices that follow client-provided specifications and standards, ensuring product consistency and compliance with detailed design requirements. ODM sewing manufacturing emphasizes internal quality assurance processes, including prototype testing and iterative improvements, to achieve high-quality, ready-to-market products. Both OEM and ODM manufacturers implement rigorous inspections, fabric testing, and adherence to industry certifications to maintain sewing quality and minimize defects.

Time-to-Market: OEM Compared to ODM in Sewing

OEM manufacturing in sewing offers faster time-to-market by producing pre-designed products, enabling brands to launch quickly without extensive development. ODM manufacturing involves designing and developing new products, which extends the lead time due to prototyping, sampling, and approvals. Brands seeking rapid product release often prefer OEM for its streamlined process and reduced development cycle.

Selecting the Right Manufacturing Model for Your Sewing Business

OEM manufacturing allows sewing businesses to produce custom-designed garments based on detailed client specifications, ensuring brand exclusivity and control over design elements. ODM manufacturing offers pre-designed patterns and ready-to-produce products, enabling faster market entry and reduced development costs. Evaluating factors like design control, time-to-market, budget constraints, and intellectual property rights is essential for selecting the right manufacturing model for your sewing enterprise.

OEM manufacturing vs ODM manufacturing Infographic

bizdif.com

bizdif.com