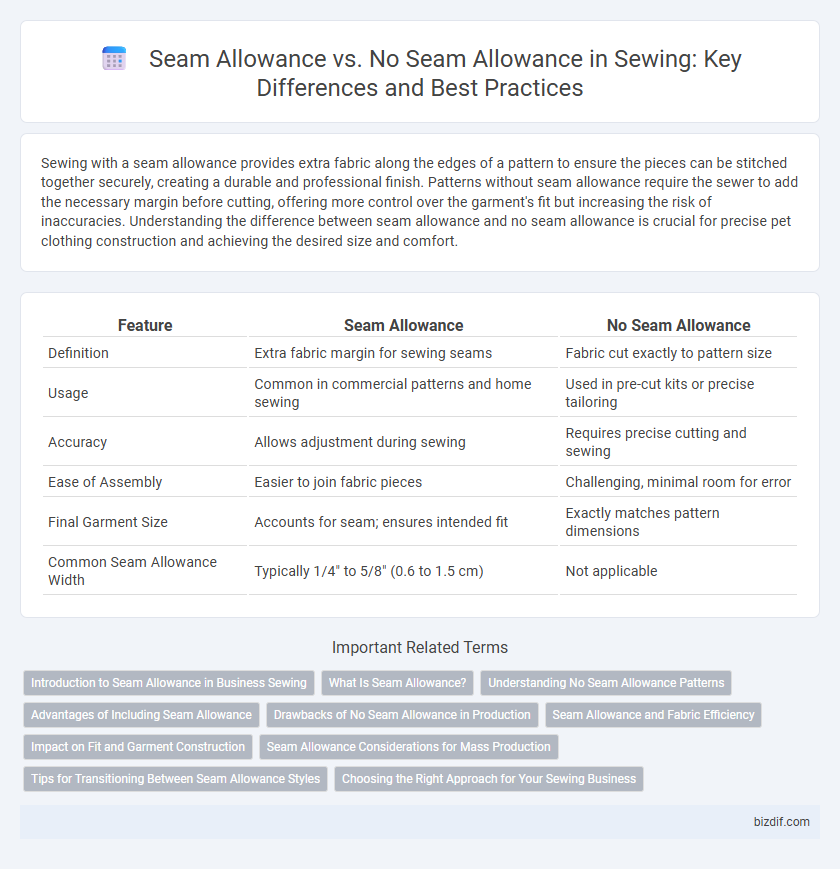

Sewing with a seam allowance provides extra fabric along the edges of a pattern to ensure the pieces can be stitched together securely, creating a durable and professional finish. Patterns without seam allowance require the sewer to add the necessary margin before cutting, offering more control over the garment's fit but increasing the risk of inaccuracies. Understanding the difference between seam allowance and no seam allowance is crucial for precise pet clothing construction and achieving the desired size and comfort.

Table of Comparison

| Feature | Seam Allowance | No Seam Allowance |

|---|---|---|

| Definition | Extra fabric margin for sewing seams | Fabric cut exactly to pattern size |

| Usage | Common in commercial patterns and home sewing | Used in pre-cut kits or precise tailoring |

| Accuracy | Allows adjustment during sewing | Requires precise cutting and sewing |

| Ease of Assembly | Easier to join fabric pieces | Challenging, minimal room for error |

| Final Garment Size | Accounts for seam; ensures intended fit | Exactly matches pattern dimensions |

| Common Seam Allowance Width | Typically 1/4" to 5/8" (0.6 to 1.5 cm) | Not applicable |

Introduction to Seam Allowance in Business Sewing

Seam allowance is the fabric area between the edge and the stitching line, crucial in business sewing for ensuring garment durability and proper fit. Including seam allowance in pattern design allows for accurate assembly and adjustments during production, minimizing fabric waste and rework costs. No seam allowance patterns require the sewer to add this margin manually, which can lead to inconsistencies and increased labor time in commercial sewing operations.

What Is Seam Allowance?

Seam allowance is the extra fabric between the edge of a garment piece and the stitching line, typically ranging from 1/4 to 5/8 inches, allowing for accurate sewing and garment assembly. Patterns with seam allowance included simplify cutting and sewing processes, while patterns without seam allowance require the sewist to add the necessary margin manually. Proper understanding of seam allowance ensures precise garment construction, preventing fit issues and fabric fraying.

Understanding No Seam Allowance Patterns

No seam allowance patterns require precise cutting and sewing directly on the edge of the fabric, eliminating the extra margin typically added for seams. This technique demands careful measurement and accurate stitching to ensure garments fit correctly without the buffer space for adjustments. Understanding no seam allowance patterns enhances fabric efficiency and can reduce material waste but leaves less room for error during construction.

Advantages of Including Seam Allowance

Including seam allowance in sewing patterns ensures precise fabric cutting and allows for accurate garment assembly, minimizing the risk of fitting errors. Seam allowances provide extra fabric needed for stitching, making alterations and adjustments easier during the sewing process. This margin also reinforces garment durability by accommodating seam stress and preventing fabric fraying at the edges.

Drawbacks of No Seam Allowance in Production

No seam allowance in production leads to significant challenges, such as reduced fabric margin for adjustments and increased risk of garment misfit. The absence of extra fabric complicates alterations, resulting in higher rejection rates and manufacturing inefficiencies. This constraint often causes increased waste and production delays, directly impacting cost-effectiveness and quality control in apparel manufacturing.

Seam Allowance and Fabric Efficiency

Seam allowance is the extra fabric between the stitching line and the edge of the fabric, crucial for garment construction and ensuring durability. Including seam allowance in patterns improves fabric efficiency by enabling precise cutting, reducing waste, and allowing for adjustments during sewing. Optimizing seam allowance sizes balances fabric use with garment strength, directly impacting both material costs and finished product quality.

Impact on Fit and Garment Construction

Seam allowance significantly affects garment fit by providing extra fabric for stitching, ensuring precise shape and structural integrity during construction. Without seam allowance, garments often lack flexibility for adjustments, leading to tighter or ill-fitting pieces and potential distortion of design lines. Properly calculated seam allowance facilitates tailoring accuracy and durability, crucial for achieving professional, comfortable clothing.

Seam Allowance Considerations for Mass Production

Seam allowance plays a critical role in mass production by ensuring consistent garment fit and durability across large batches. Specifying precise seam allowances reduces fabric waste and streamlines assembly, optimizing both cost-efficiency and quality control. Designers and manufacturers must balance standard seam widths with fabric type and stitch method to maintain production speed without sacrificing structural integrity.

Tips for Transitioning Between Seam Allowance Styles

When transitioning between seam allowance styles, carefully adjust your patterns by marking new cutting lines to ensure accurate fabric dimensions. Use consistent seam allowance widths to simplify sewing and avoid fitting issues, especially when combining pieces with differing allowances. Test on scrap fabric to check seam integrity and garment fit before cutting the final material.

Choosing the Right Approach for Your Sewing Business

Selecting between seam allowance and no seam allowance patterns critically impacts fabric consumption, production efficiency, and garment fit accuracy in your sewing business. Patterns with pre-included seam allowances simplify cutting and sewing processes, reducing errors and saving time, while no seam allowance patterns offer greater flexibility for customization and precise fitting adjustments. Evaluating project requirements, target market preferences, and skill level allows you to choose the appropriate method that optimizes material usage, enhances product quality, and supports scalable business operations.

Seam Allowance vs No Seam Allowance Infographic

bizdif.com

bizdif.com