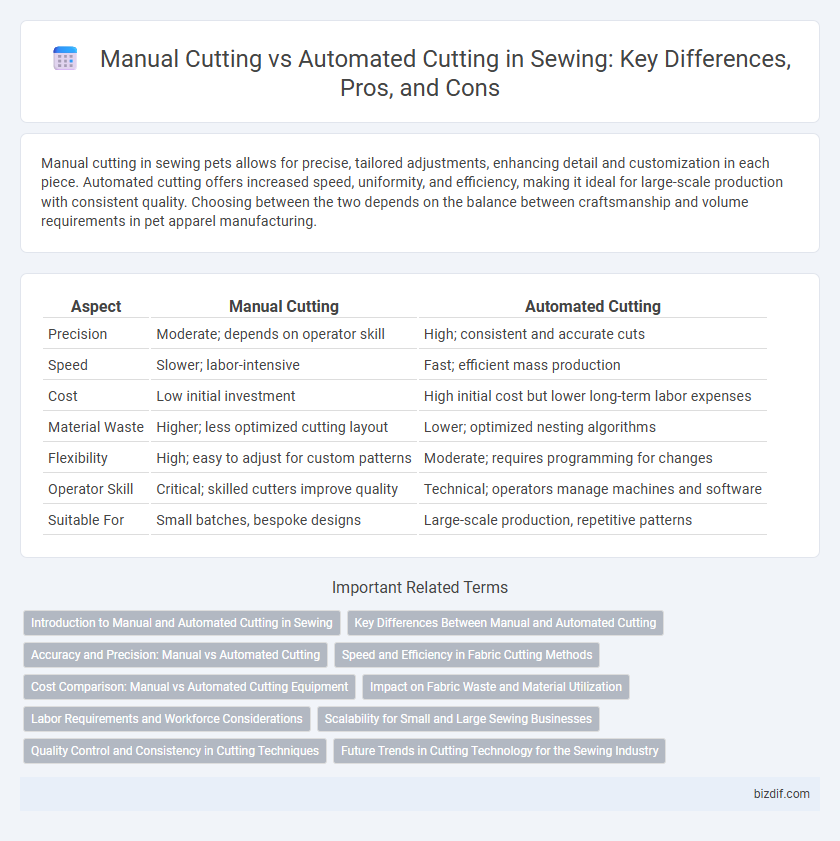

Manual cutting in sewing pets allows for precise, tailored adjustments, enhancing detail and customization in each piece. Automated cutting offers increased speed, uniformity, and efficiency, making it ideal for large-scale production with consistent quality. Choosing between the two depends on the balance between craftsmanship and volume requirements in pet apparel manufacturing.

Table of Comparison

| Aspect | Manual Cutting | Automated Cutting |

|---|---|---|

| Precision | Moderate; depends on operator skill | High; consistent and accurate cuts |

| Speed | Slower; labor-intensive | Fast; efficient mass production |

| Cost | Low initial investment | High initial cost but lower long-term labor expenses |

| Material Waste | Higher; less optimized cutting layout | Lower; optimized nesting algorithms |

| Flexibility | High; easy to adjust for custom patterns | Moderate; requires programming for changes |

| Operator Skill | Critical; skilled cutters improve quality | Technical; operators manage machines and software |

| Suitable For | Small batches, bespoke designs | Large-scale production, repetitive patterns |

Introduction to Manual and Automated Cutting in Sewing

Manual cutting in sewing involves using handheld tools like scissors or rotary cutters to trim fabric, offering precision and control for small-scale or intricate projects. Automated cutting employs computer-controlled machines that enhance speed, accuracy, and repeatability, especially beneficial for mass production and complex patterns. Choosing between manual and automated cutting depends on factors such as production volume, fabric type, and required precision.

Key Differences Between Manual and Automated Cutting

Manual cutting in sewing involves using handheld tools like scissors or rotary cutters, offering high precision for intricate designs but limited speed and consistency. Automated cutting employs computer-controlled machines such as CNC fabric cutters, delivering faster production rates, uniform cuts, and reduced material waste. Key differences include labor intensity, accuracy, scalability, and integration with digital design software.

Accuracy and Precision: Manual vs Automated Cutting

Manual cutting in sewing often results in variability due to human error, affecting both accuracy and precision in fabric shapes and sizes. Automated cutting uses advanced CNC machines and laser cutters, ensuring consistent and highly precise cuts that match exact digital patterns. This technology minimizes material waste and improves overall garment quality by delivering uniform pieces every time.

Speed and Efficiency in Fabric Cutting Methods

Automated cutting machines significantly increase speed and efficiency in fabric cutting by precisely slicing multiple layers simultaneously, reducing human error and material waste. Manual cutting depends heavily on skilled labor and is slower, making it less suitable for high-volume production but advantageous for intricate, custom designs. Industries focusing on mass production prioritize automated cutting to maximize output and consistency while lowering overall operational costs.

Cost Comparison: Manual vs Automated Cutting Equipment

Manual cutting equipment generally involves lower upfront costs, making it accessible for small-scale sewing operations or startups. Automated cutting machines require significant initial investment but offer higher precision and faster production, reducing labor costs and material waste over time. In long-term production scenarios, automated cutting equipment tends to deliver a better return on investment due to increased efficiency and consistent quality.

Impact on Fabric Waste and Material Utilization

Manual cutting in sewing often results in higher fabric waste due to human error and less precise pattern placement, leading to inefficient material utilization. Automated cutting systems use advanced software and machinery to optimize pattern layouts, significantly reducing fabric waste and maximizing material usage. This efficiency not only lowers production costs but also supports sustainable manufacturing practices by minimizing excess fabric disposal.

Labor Requirements and Workforce Considerations

Manual cutting in sewing demands skilled labor with precision and experience, leading to higher labor costs and increased production time. Automated cutting machines reduce workforce requirements by increasing cutting speed and accuracy, allowing fewer operators to handle larger volumes efficiently. Workforce considerations include the need for training in machine operation for automated systems and potential job displacement for manual cutters.

Scalability for Small and Large Sewing Businesses

Manual cutting offers precise control and flexibility, ideal for small sewing businesses with limited production volumes, but it struggles to scale efficiently as order sizes increase. Automated cutting systems significantly enhance scalability by rapidly processing large fabric quantities with consistent accuracy, benefiting large sewing operations aiming to boost productivity. Investing in automated cutting technology enables seamless expansion and cost-effectiveness for businesses targeting higher output levels.

Quality Control and Consistency in Cutting Techniques

Manual cutting offers greater control for intricate designs but often results in variability due to human error, impacting the overall quality and consistency of the fabric pieces. Automated cutting machines utilize precise, computer-controlled blades that enhance consistency and reduce fabric waste, ensuring uniformity across multiple production runs. Quality control is significantly improved with automation, as the reproducibility of cutting patterns minimizes defects and supports scalable garment manufacturing.

Future Trends in Cutting Technology for the Sewing Industry

Future trends in cutting technology for the sewing industry emphasize the integration of AI-driven automated cutting machines that enhance precision, reduce material waste, and accelerate production speed. Advanced laser and ultrasonic cutting systems offer non-contact cutting solutions, minimizing fabric distortion and enabling complex pattern designs. The convergence of IoT-enabled equipment with data analytics facilitates real-time monitoring and predictive maintenance, optimizing workflow efficiency and lowering operational costs.

Manual cutting vs Automated cutting Infographic

bizdif.com

bizdif.com