Batch sewing offers efficiency and consistency by producing multiple pet garments simultaneously, ideal for standard sizes and common designs. Bespoke tailoring provides personalized fit and unique customization, ensuring each piece meets the specific needs and comforts of individual pets. Choosing between batch sewing and bespoke tailoring depends on the balance between quantity, cost, and personalized attention in pet apparel creation.

Table of Comparison

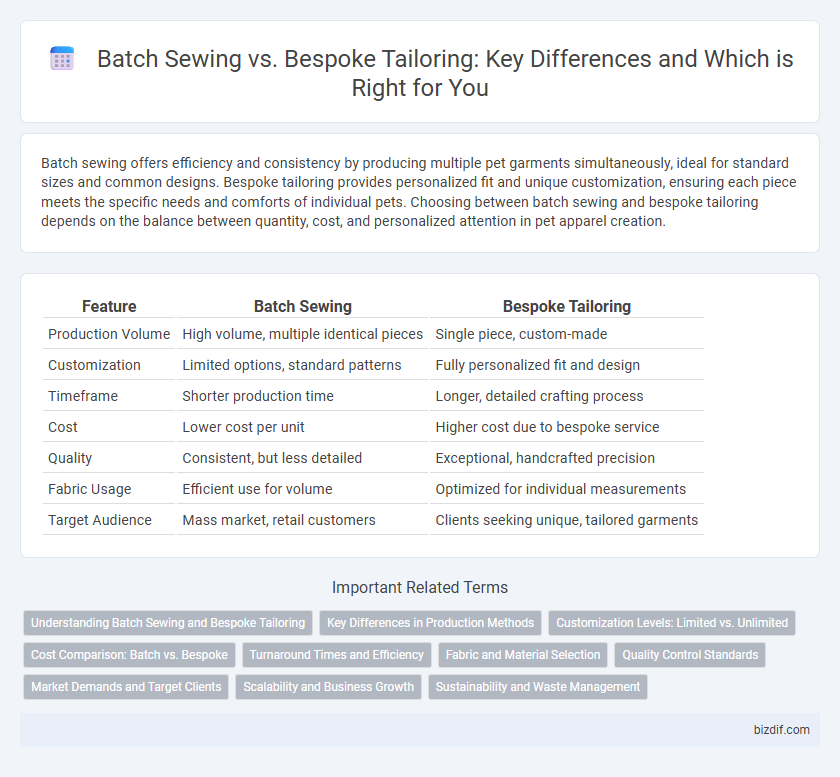

| Feature | Batch Sewing | Bespoke Tailoring |

|---|---|---|

| Production Volume | High volume, multiple identical pieces | Single piece, custom-made |

| Customization | Limited options, standard patterns | Fully personalized fit and design |

| Timeframe | Shorter production time | Longer, detailed crafting process |

| Cost | Lower cost per unit | Higher cost due to bespoke service |

| Quality | Consistent, but less detailed | Exceptional, handcrafted precision |

| Fabric Usage | Efficient use for volume | Optimized for individual measurements |

| Target Audience | Mass market, retail customers | Clients seeking unique, tailored garments |

Understanding Batch Sewing and Bespoke Tailoring

Batch sewing involves producing garments in large quantities using standardized patterns and processes, ensuring efficiency and cost-effectiveness for mass markets. Bespoke tailoring, on the other hand, emphasizes custom-made clothing tailored to an individual's specific measurements and preferences, providing superior fit and personalized craftsmanship. Understanding these approaches highlights the contrast between high-volume production and exclusive, made-to-measure garment creation.

Key Differences in Production Methods

Batch sewing involves producing multiple identical garments simultaneously using standardized patterns and automated machinery for efficiency and cost-effectiveness. Bespoke tailoring centers on creating custom-fitted garments crafted individually with hand-sewn techniques, emphasizing precision and personalization. The key difference lies in batch sewing's focus on volume and uniformity compared to bespoke tailoring's dedication to individual fit and detailed craftsmanship.

Customization Levels: Limited vs. Unlimited

Batch sewing offers limited customization options as garments are produced in groups using standardized patterns and sizes, ensuring consistency and efficiency. Bespoke tailoring provides unlimited customization, allowing precise adjustments to fabric, fit, style, and detailing based on individual client measurements and preferences. This personalized approach results in unique, perfectly fitting garments tailored exclusively for each customer.

Cost Comparison: Batch vs. Bespoke

Batch sewing reduces production costs significantly by utilizing standardized patterns and bulk fabric purchasing, which lowers per-unit expenses. Bespoke tailoring involves higher costs due to customized measurements, handcrafted details, and premium materials tailored to individual clients. Overall, batch sewing offers more economical solutions for mass production, while bespoke tailoring justifies its premium pricing through unique craftsmanship and personalized fit.

Turnaround Times and Efficiency

Batch sewing significantly reduces turnaround times by producing multiple garments simultaneously using standardized patterns and processes, enhancing overall efficiency in manufacturing. Bespoke tailoring, though time-intensive due to custom measurements and handcrafting, offers unparalleled precision and personalization but results in longer production cycles. Efficiency in batch sewing suits mass production demands, while bespoke tailoring prioritizes individualized quality over speed.

Fabric and Material Selection

Batch sewing utilizes standardized fabric selections optimized for mass production, ensuring consistent quality and cost efficiency across multiple garments. Bespoke tailoring emphasizes personalized material choices, often sourcing premium or unique fabrics tailored to individual customer preferences and specific garment requirements. This distinction significantly impacts the texture, durability, and overall aesthetic outcome of the finished product.

Quality Control Standards

Batch sewing relies on standardized quality control protocols to ensure consistency across large quantities, with systematic inspections at each production stage. Bespoke tailoring emphasizes meticulous, individualized quality assessments, focusing on precision and unique fabric handling to meet specific client measurements and preferences. Both methods maintain rigorous standards, but bespoke tailoring achieves higher customization and detail accuracy through personalized quality checks.

Market Demands and Target Clients

Batch sewing efficiently meets high market demands by producing large quantities of standardized garments for budget-conscious consumers and retail brands. Bespoke tailoring targets niche clients seeking personalized, high-quality apparel with custom fit and exclusive designs, often at a premium price. Market trends reveal rising interest in sustainable fashion, boosting demand for bespoke tailoring despite the prevalence of batch sewing in mass production.

Scalability and Business Growth

Batch sewing enables scalability by producing large quantities of garments efficiently, reducing costs and meeting high demand quickly. Bespoke tailoring, while offering personalized and high-quality garments, limits scalability due to its labor-intensive and time-consuming nature. Businesses aiming for rapid growth often prefer batch sewing to maximize production capacity and revenue streams.

Sustainability and Waste Management

Batch sewing produces items in large quantities, optimizing fabric use and reducing waste through streamlined cutting and sewing processes. Bespoke tailoring customizes each garment, often resulting in higher material efficiency and less surplus fabric due to precise measurements and minimal overproduction. Sustainable practices in both methods emphasize minimizing textile waste, recycling scraps, and using eco-friendly materials to enhance environmental responsibility in clothing production.

Batch sewing vs bespoke tailoring Infographic

bizdif.com

bizdif.com