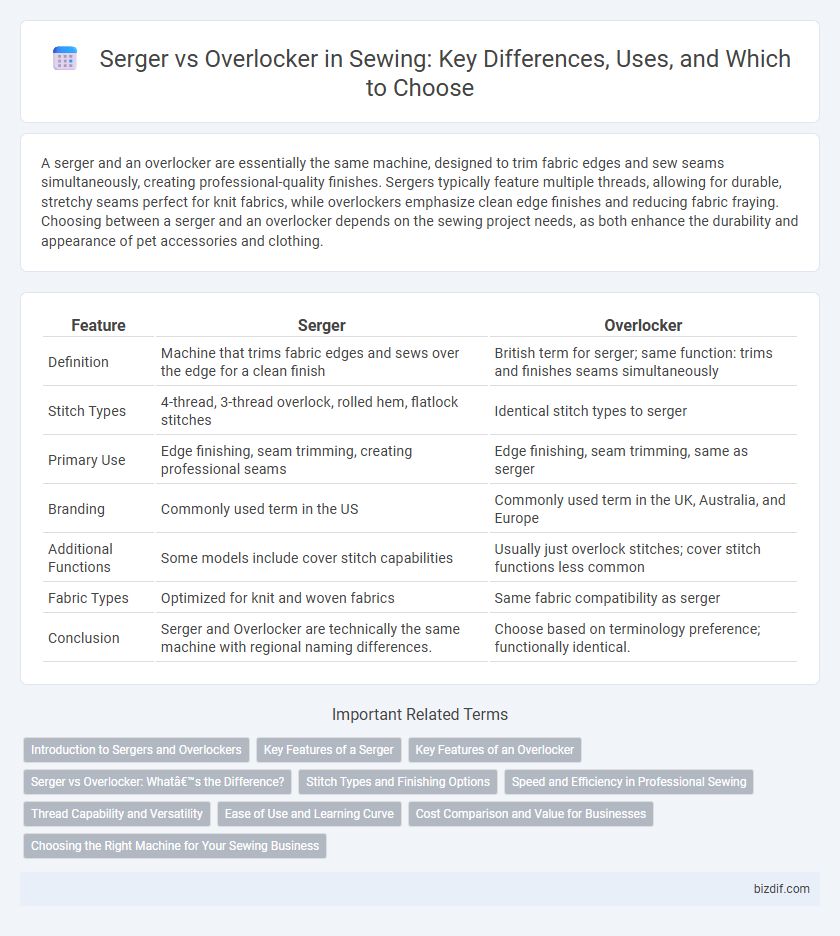

A serger and an overlocker are essentially the same machine, designed to trim fabric edges and sew seams simultaneously, creating professional-quality finishes. Sergers typically feature multiple threads, allowing for durable, stretchy seams perfect for knit fabrics, while overlockers emphasize clean edge finishes and reducing fabric fraying. Choosing between a serger and an overlocker depends on the sewing project needs, as both enhance the durability and appearance of pet accessories and clothing.

Table of Comparison

| Feature | Serger | Overlocker |

|---|---|---|

| Definition | Machine that trims fabric edges and sews over the edge for a clean finish | British term for serger; same function: trims and finishes seams simultaneously |

| Stitch Types | 4-thread, 3-thread overlock, rolled hem, flatlock stitches | Identical stitch types to serger |

| Primary Use | Edge finishing, seam trimming, creating professional seams | Edge finishing, seam trimming, same as serger |

| Branding | Commonly used term in the US | Commonly used term in the UK, Australia, and Europe |

| Additional Functions | Some models include cover stitch capabilities | Usually just overlock stitches; cover stitch functions less common |

| Fabric Types | Optimized for knit and woven fabrics | Same fabric compatibility as serger |

| Conclusion | Serger and Overlocker are technically the same machine with regional naming differences. | Choose based on terminology preference; functionally identical. |

Introduction to Sergers and Overlockers

Sergers and overlockers are specialized sewing machines designed to trim fabric edges while simultaneously stitching to prevent fraying. These machines create strong, professional seams by sewing over the edge of the fabric, using multiple threads for durability and flexibility. Commonly used in garment construction, sergers and overlockers enhance finished products with clean, secure hems and seams.

Key Features of a Serger

A serger combines stitches, trims fabric edges, and encloses seams in a single step with multiple threads, typically ranging from 3 to 5, enhancing garment durability and professional finish. It features differential feed mechanisms for handling various fabric types without puckering and offers adjustable stitch widths and lengths for customization. Industrial-strength needles and high-speed stitching capabilities make sergers ideal for efficient, precise edge finishing in sewing projects.

Key Features of an Overlocker

An overlocker, also known as a serger, is designed to trim fabric edges while simultaneously stitching, providing a clean, professional finish that prevents fraying. Key features include multiple thread options--typically three to five threads--for durable seam construction, differential feed to handle various fabric types without puckering, and customizable stitch width and length for versatile project applications. Integrated cutting blades and color-coded threading systems enhance precision and ease of use during garment assembly.

Serger vs Overlocker: What’s the Difference?

A serger and an overlocker both trim fabric edges and sew seams simultaneously, but the terms differ by region: "serger" is commonly used in North America, while "overlocker" is preferred in Europe and other parts of the world. Sergers typically feature multiple threads (usually 3-4) to create strong, stretchy seams ideal for knit materials, while overlockers offer various stitch types, including 2, 3, and 4-thread options for finishing edges with precision. Understanding these regional terminologies helps sewists choose the right machine for professional seam finishes and garment construction.

Stitch Types and Finishing Options

Serger and overlocker machines both create professional stitch types like 3-thread, 4-thread, and rolled hems, enhancing garment durability and stretch. Sergers excel in combining seam stitching with edge finishing in one pass, while overlockers offer refined edge trims and allow variable stitch widths for intricate detailing. Finishing options include clean edges, seam reinforcement, and decorative hems, essential for quality sewing projects requiring strong, flexible seams.

Speed and Efficiency in Professional Sewing

A serger and an overlocker both enhance speed and efficiency in professional sewing by simultaneously trimming, stitching, and finishing fabric edges. Sergers typically offer higher stitch speeds, reaching up to 1500 stitches per minute, which significantly reduces production time for large-scale garment manufacturing. Overlockers provide versatile stitch options and seamless fabric edge clean finishes, optimizing workflow without sacrificing quality in high-volume sewing environments.

Thread Capability and Versatility

Sergers typically use 3 to 5 threads, allowing for strong, stretchable seams ideal for knit fabrics, while overlockers generally handle 2 to 4 threads, focusing on edge finishing and trimming with less seam stretch. The thread capability in sergers supports complex stitching patterns such as rolled hems and flatlock seams, enhancing garment durability and elasticity. Overlockers prioritize versatility in finishing various fabric edges quickly but offer fewer threading options, limiting their use in highly elastic or decorative seam applications.

Ease of Use and Learning Curve

Serger and overlocker machines both streamline fabric finishing, but Sergers tend to have a steeper learning curve due to complex threading and multiple functions. Overlockers are generally more user-friendly for beginners, offering simpler threading systems and straightforward stitch options. Mastery of either requires practice, but overlockers often ease the transition for those new to garment construction.

Cost Comparison and Value for Businesses

A serger typically costs between $300 and $1,500, while industrial overlockers range from $1,000 to over $5,000, reflecting their enhanced durability and production speed for businesses. Investing in a high-quality overlocker offers greater long-term value for enterprises due to faster stitching rates and reduced maintenance compared to budget sergers. Small businesses may prioritize cost-effective sergers for lower initial expenses, but growing manufacturers benefit more from overlockers' efficiency and capacity for high-volume output.

Choosing the Right Machine for Your Sewing Business

Choosing between a serger and an overlocker depends on the specific sewing business needs such as fabric types, seam finishes, and production speed. Sergers typically offer multi-thread stitching with cutting functions perfect for professional garment construction, while overlockers excel in edging and preventing fabric fraying. Evaluating machine features like stitch variety, speed, and maintenance requirements ensures the right equipment enhances efficiency and product quality.

Serger vs Overlocker Infographic

bizdif.com

bizdif.com