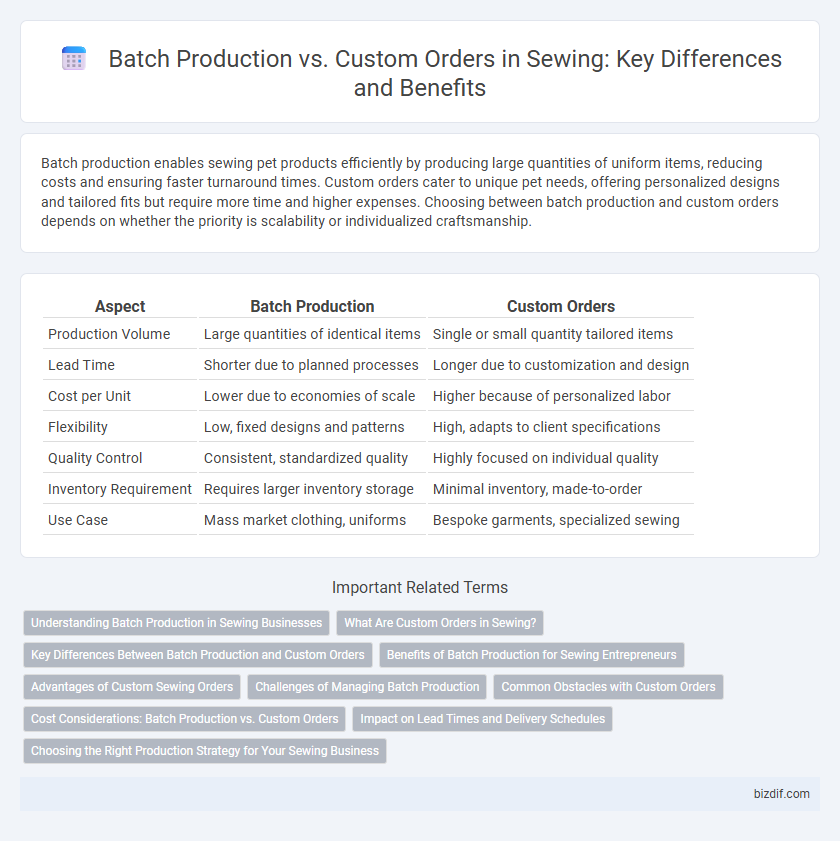

Batch production enables sewing pet products efficiently by producing large quantities of uniform items, reducing costs and ensuring faster turnaround times. Custom orders cater to unique pet needs, offering personalized designs and tailored fits but require more time and higher expenses. Choosing between batch production and custom orders depends on whether the priority is scalability or individualized craftsmanship.

Table of Comparison

| Aspect | Batch Production | Custom Orders |

|---|---|---|

| Production Volume | Large quantities of identical items | Single or small quantity tailored items |

| Lead Time | Shorter due to planned processes | Longer due to customization and design |

| Cost per Unit | Lower due to economies of scale | Higher because of personalized labor |

| Flexibility | Low, fixed designs and patterns | High, adapts to client specifications |

| Quality Control | Consistent, standardized quality | Highly focused on individual quality |

| Inventory Requirement | Requires larger inventory storage | Minimal inventory, made-to-order |

| Use Case | Mass market clothing, uniforms | Bespoke garments, specialized sewing |

Understanding Batch Production in Sewing Businesses

Batch production in sewing businesses involves creating multiple identical garments simultaneously, maximizing efficiency and reducing material waste through standardized processes. This method leverages economies of scale by streamlining tasks such as cutting, sewing, and finishing, which lowers per-unit costs compared to custom orders. Understanding batch production helps sewing companies optimize inventory management and meet larger market demands with consistent quality.

What Are Custom Orders in Sewing?

Custom orders in sewing refer to uniquely tailored garments or textiles created to meet specific client measurements, design preferences, and material choices, ensuring a personalized fit and style. This approach contrasts with batch production, where multiple identical items are produced simultaneously to maximize efficiency and reduce costs. Custom sewing enhances product exclusivity and customer satisfaction by allowing detailed adjustments, often involving complex handcrafting techniques and individualized pattern making.

Key Differences Between Batch Production and Custom Orders

Batch production in sewing involves creating large quantities of identical garments using standardized processes, optimizing efficiency and reducing per-unit costs. Custom orders focus on unique, made-to-measure items tailored to individual specifications, prioritizing quality and personalization over speed. Key differences include production volume, lead time, and flexibility, with batch production excelling in consistency and custom orders emphasizing individuality.

Benefits of Batch Production for Sewing Entrepreneurs

Batch production offers sewing entrepreneurs advantages such as increased efficiency and reduced material costs by producing multiple identical items simultaneously. This method streamlines workflow, minimizes machine setup times, and enhances consistent quality control across the products. Leveraging batch production enables faster order fulfillment and better scalability for small to medium sewing businesses.

Advantages of Custom Sewing Orders

Custom sewing orders provide tailor-made garments that perfectly fit individual measurements, enhancing comfort and style. This approach allows for unique designs and fabric choices, meeting specific client preferences and reducing waste. Increased customer satisfaction and loyalty often result from personalized service and attention to detail in custom sewing projects.

Challenges of Managing Batch Production

Managing batch production in sewing presents challenges such as maintaining consistent quality across multiple units and coordinating efficient workflow to meet deadlines. Inventory management becomes complex due to the need for bulk materials, which can lead to excess waste or shortages. Balancing machine usage and labor allocation without disrupting production schedules requires precise planning and monitoring.

Common Obstacles with Custom Orders

Custom orders in sewing often face challenges such as fluctuating fabric availability, leading to delays in production timelines. Precise measurements and individual design preferences increase the risk of errors and require meticulous quality checks. Managing personalized fittings and adjustments demands additional labor and coordination, complicating workflow efficiency compared to batch production.

Cost Considerations: Batch Production vs. Custom Orders

Batch production reduces per-unit costs by leveraging economies of scale and minimizing setup times, making it cost-effective for large quantities of standardized sewing items. Custom orders typically involve higher costs due to individualized design, tailoring, and frequent adjustments, resulting in increased labor and material expenses. Choosing between batch production and custom orders depends on balancing cost efficiency against the need for unique, personalized garments.

Impact on Lead Times and Delivery Schedules

Batch production in sewing significantly reduces lead times by enabling mass fabrication of standardized garments, optimizing machine use and labor allocation. Custom orders typically extend delivery schedules due to unique design requirements and additional fittings, necessitating flexible workflow management and precise material handling. Efficient coordination of batch runs and custom projects enhances overall production agility and meets diverse client deadlines.

Choosing the Right Production Strategy for Your Sewing Business

Batch production in sewing offers efficiency by producing large quantities of identical items, reducing per-unit costs and streamlining workflow. Custom orders prioritize personalization, allowing for unique designs and tailored fits that meet specific customer preferences but may require longer turnaround times and higher labor costs. Selecting the right production strategy depends on factors such as target market demand, production capacity, and profit margin goals within your sewing business.

Batch production vs custom orders Infographic

bizdif.com

bizdif.com