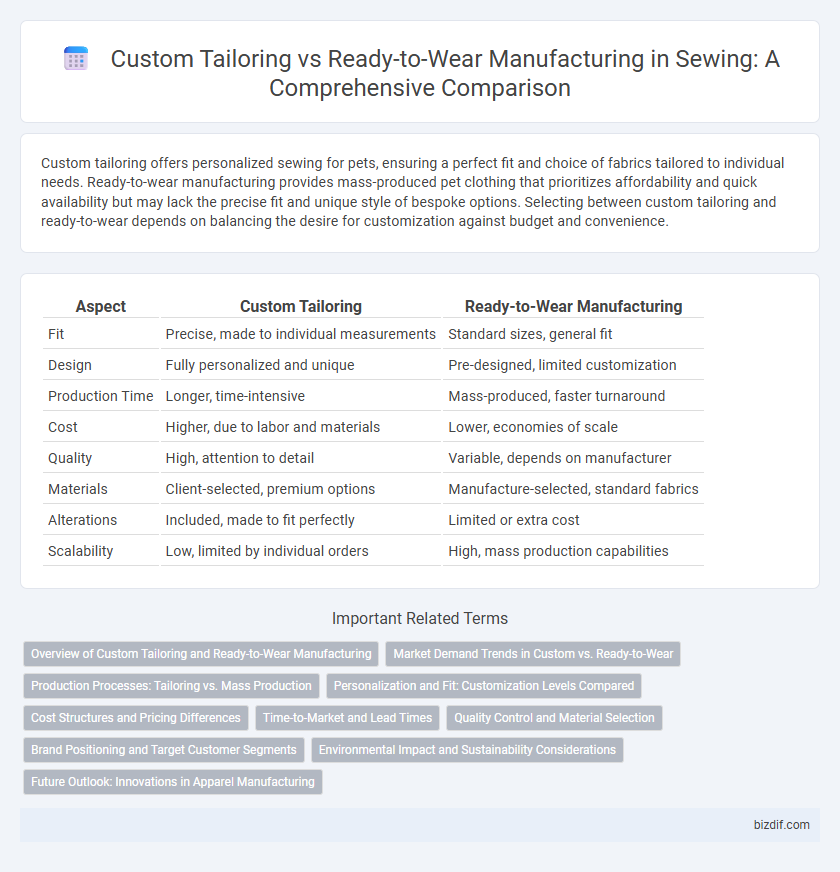

Custom tailoring offers personalized sewing for pets, ensuring a perfect fit and choice of fabrics tailored to individual needs. Ready-to-wear manufacturing provides mass-produced pet clothing that prioritizes affordability and quick availability but may lack the precise fit and unique style of bespoke options. Selecting between custom tailoring and ready-to-wear depends on balancing the desire for customization against budget and convenience.

Table of Comparison

| Aspect | Custom Tailoring | Ready-to-Wear Manufacturing |

|---|---|---|

| Fit | Precise, made to individual measurements | Standard sizes, general fit |

| Design | Fully personalized and unique | Pre-designed, limited customization |

| Production Time | Longer, time-intensive | Mass-produced, faster turnaround |

| Cost | Higher, due to labor and materials | Lower, economies of scale |

| Quality | High, attention to detail | Variable, depends on manufacturer |

| Materials | Client-selected, premium options | Manufacture-selected, standard fabrics |

| Alterations | Included, made to fit perfectly | Limited or extra cost |

| Scalability | Low, limited by individual orders | High, mass production capabilities |

Overview of Custom Tailoring and Ready-to-Wear Manufacturing

Custom tailoring involves creating garments specifically designed and fitted to an individual's measurements, ensuring personalized style, precise fit, and unique fabric choices. Ready-to-wear manufacturing produces standardized clothing in bulk, using set sizes for mass market distribution, prioritizing efficiency and affordability over customization. The distinction highlights the trade-off between bespoke quality and scalable production in the fashion industry.

Market Demand Trends in Custom vs. Ready-to-Wear

Market demand trends indicate a growing preference for custom tailoring as consumers seek personalized fit and unique designs. Ready-to-wear manufacturing maintains strong market share due to affordability and mass accessibility, appealing to budget-conscious shoppers. The rise of technology-driven customization options is narrowing the gap, blending efficiency with personalization in both sectors.

Production Processes: Tailoring vs. Mass Production

Custom tailoring involves meticulous handcrafting where skilled artisans measure, cut, and sew garments to fit individual body shapes, ensuring precision and personalization in every stitch. Ready-to-wear manufacturing relies on automated, high-speed machinery and standardized sizing, enabling large-scale production that prioritizes efficiency and cost-effectiveness over customization. The contrast in production processes highlights how tailoring emphasizes quality and fit, while mass production focuses on volume and speed.

Personalization and Fit: Customization Levels Compared

Custom tailoring offers unparalleled personalization, allowing garments to be meticulously crafted to an individual's exact measurements, body shape, and style preferences, resulting in a perfect fit. Ready-to-wear manufacturing relies on standardized sizes, which may not accommodate unique body proportions, often leading to compromises in fit and comfort. The level of customization in bespoke tailoring significantly enhances garment fit and personal expression compared to the mass production approach of ready-to-wear clothing.

Cost Structures and Pricing Differences

Custom tailoring involves higher labor costs due to personalized measurements and hand-finished details, resulting in premium pricing compared to ready-to-wear manufacturing. Ready-to-wear benefits from economies of scale, automated production lines, and bulk materials sourcing, which significantly lowers unit costs and retail prices. The cost structure of custom tailoring includes bespoke fabric selection and fittings, while ready-to-wear relies on standardized sizes and mass production to drive affordability.

Time-to-Market and Lead Times

Custom tailoring requires significantly longer lead times, often ranging from several days to weeks, due to personalized measurements, fabric selection, and handcrafting processes. In contrast, ready-to-wear manufacturing emphasizes rapid time-to-market through mass production and standardized sizing, enabling retailers to replenish inventory swiftly and meet seasonal demand. Brands seeking agility typically favor ready-to-wear for its efficiency, while custom tailoring prioritizes fit and exclusivity over speed.

Quality Control and Material Selection

Custom tailoring ensures superior quality control through meticulous handcrafting and personalized fittings, allowing for precise adjustments to achieve an impeccable fit. Material selection in custom tailoring involves premium, often exclusive fabrics chosen specifically for each garment, enhancing durability and comfort. Ready-to-wear manufacturing relies on standardized quality checks and mass-produced materials, which may limit the customization of fabric choices and detailed craftsmanship.

Brand Positioning and Target Customer Segments

Custom tailoring emphasizes personalized fit and exclusive craftsmanship, attracting high-income clientele seeking unique, luxury wardrobe pieces. Ready-to-wear manufacturing targets mass-market consumers prioritizing affordability, convenience, and trend-driven fashion cycles. Brand positioning in custom tailoring revolves around exclusivity and bespoke service, while ready-to-wear brands focus on accessibility and scalability.

Environmental Impact and Sustainability Considerations

Custom tailoring reduces fabric waste by using precise measurements and minimizing overproduction, unlike ready-to-wear manufacturing which often leads to excess inventory and discarded garments. Sustainable fabrics and eco-friendly dyes are more commonly integrated into bespoke tailoring processes, enhancing environmental responsibility. The localized production of custom clothing also lowers carbon emissions compared to mass-produced clothing transported globally.

Future Outlook: Innovations in Apparel Manufacturing

Custom tailoring is integrating advanced technologies like 3D body scanning and AI-driven pattern making to offer precise fit and personalized designs, enhancing customer satisfaction. Ready-to-wear manufacturing is adopting automation and sustainable materials to increase production speed and reduce environmental impact. Both sectors are converging through digital customization platforms, signaling a future where bespoke quality meets mass production efficiency.

Custom tailoring vs ready-to-wear manufacturing Infographic

bizdif.com

bizdif.com