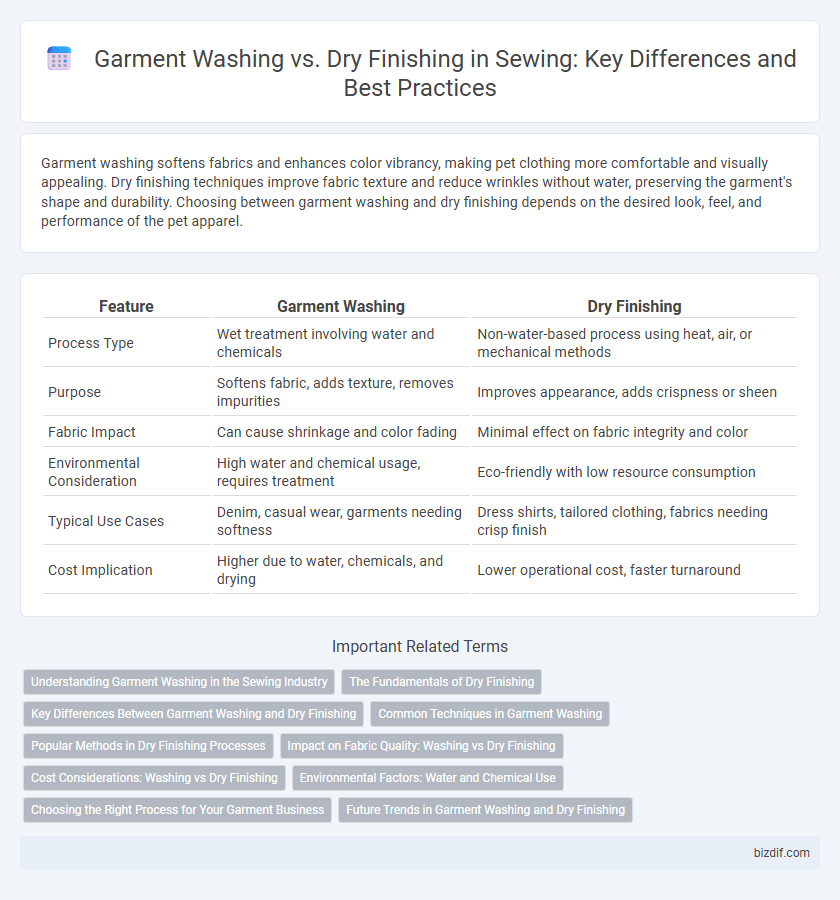

Garment washing softens fabrics and enhances color vibrancy, making pet clothing more comfortable and visually appealing. Dry finishing techniques improve fabric texture and reduce wrinkles without water, preserving the garment's shape and durability. Choosing between garment washing and dry finishing depends on the desired look, feel, and performance of the pet apparel.

Table of Comparison

| Feature | Garment Washing | Dry Finishing |

|---|---|---|

| Process Type | Wet treatment involving water and chemicals | Non-water-based process using heat, air, or mechanical methods |

| Purpose | Softens fabric, adds texture, removes impurities | Improves appearance, adds crispness or sheen |

| Fabric Impact | Can cause shrinkage and color fading | Minimal effect on fabric integrity and color |

| Environmental Consideration | High water and chemical usage, requires treatment | Eco-friendly with low resource consumption |

| Typical Use Cases | Denim, casual wear, garments needing softness | Dress shirts, tailored clothing, fabrics needing crisp finish |

| Cost Implication | Higher due to water, chemicals, and drying | Lower operational cost, faster turnaround |

Understanding Garment Washing in the Sewing Industry

Garment washing in the sewing industry involves multiple processes such as stone washing, enzyme washing, and acid washing to enhance fabric softness, color, and texture, ensuring a worn-in appearance. This technique improves garment durability and comfort, removing residual chemicals from manufacturing while achieving desired aesthetic effects. Fabric types like denim and cotton are commonly subjected to garment washing to meet fashion trends and consumer preferences effectively.

The Fundamentals of Dry Finishing

Dry finishing in garment production primarily involves techniques like pressing, steaming, and curing to enhance fabric texture and appearance without using water. This method preserves the garment's shape, color, and structural integrity, contrasting with garment washing that softens textiles but can cause shrinkage or color fading. Mastery of dry finishing optimizes fabric durability and visual appeal, making it essential in maintaining garment quality during the final stages of production.

Key Differences Between Garment Washing and Dry Finishing

Garment washing involves soaking and treating fabric with water and chemicals to achieve softness, colorfastness, and a worn-in look, while dry finishing uses mechanical methods like heat and pressure without water to enhance texture and appearance. Washing processes can remove impurities and add durability, whereas dry finishing focuses on surface smoothness, wrinkle resistance, and shaping. Fabric care and final garment attributes differ significantly, with washing altering fabric weight and hand feel, and dry finishing primarily affecting the garment's structural integrity and finish.

Common Techniques in Garment Washing

Common garment washing techniques include stone washing, enzyme washing, and acid washing, which enhance fabric softness, color, and texture. These processes involve specialized equipment such as washing machines with abrasive materials or chemicals to achieve varied aesthetic effects. Controlled water temperature, chemical concentration, and washing duration are critical factors ensuring consistent garment quality and appearance.

Popular Methods in Dry Finishing Processes

Popular methods in dry finishing processes for garments include pressing, heat setting, and calendaring, which enhance fabric appearance and texture without water. Heat setting stabilizes synthetic fibers, preventing shrinkage and improving durability, while pressing removes wrinkles to ensure a crisp finish. Calendaring uses rollers to create smooth, glossy surfaces or embossed patterns, increasing the fabric's aesthetic appeal and functionality.

Impact on Fabric Quality: Washing vs Dry Finishing

Garment washing involves the use of water and chemicals to soften fabrics, remove residues, and create specific aesthetic effects, which can slightly weaken fiber strength but enhances comfort and appearance. Dry finishing processes, such as heat setting or calendaring, improve fabric texture and stability without the moisture exposure, preserving tensile strength and colorfastness more effectively. Choosing between garment washing and dry finishing depends on the desired balance between fabric softness, durability, and visual appeal in garment production.

Cost Considerations: Washing vs Dry Finishing

Garment washing typically incurs higher costs due to water, detergents, and energy consumption, as well as longer processing times compared to dry finishing, which relies on chemical treatments and air drying. Dry finishing often reduces water usage and waste management expenses, making it more economical for large-scale production aiming for minimal environmental impact. Prioritizing cost-efficiency depends on fabric type, desired finish, and production volume, where dry finishing can offer significant savings in utility bills and turnaround time.

Environmental Factors: Water and Chemical Use

Garment washing consumes significant volumes of water and utilizes various chemicals, contributing to water pollution and high energy consumption in textile processing. Dry finishing techniques, which rely on heat or mechanical processes rather than water, drastically reduce water usage and chemical discharge, resulting in a lower environmental footprint. Selecting dry finishing methods supports sustainable garment production by minimizing water contamination and conserving vital resources.

Choosing the Right Process for Your Garment Business

Selecting the appropriate finishing process depends on fabric type, desired garment texture, and target market preferences. Garment washing enhances softness, color vibrancy, and a worn-in look, ideal for casual or denim products, while dry finishing provides a crisp, polished appearance suited for formal or structured garments. Evaluating production costs, environmental impact, and brand identity ensures an optimal balance between quality and sustainability in your garment business.

Future Trends in Garment Washing and Dry Finishing

Future trends in garment washing emphasize eco-friendly technologies such as enzymatic and ozone washing to reduce water and chemical use, meeting sustainability demands in fashion. Dry finishing techniques are advancing with innovations like plasma treatment and laser finishing, enhancing fabric durability and texture without water consumption. Integration of smart automation and AI-driven process controls is expected to optimize both garment washing and dry finishing for higher efficiency and consistent quality.

Garment Washing vs Dry Finishing Infographic

bizdif.com

bizdif.com