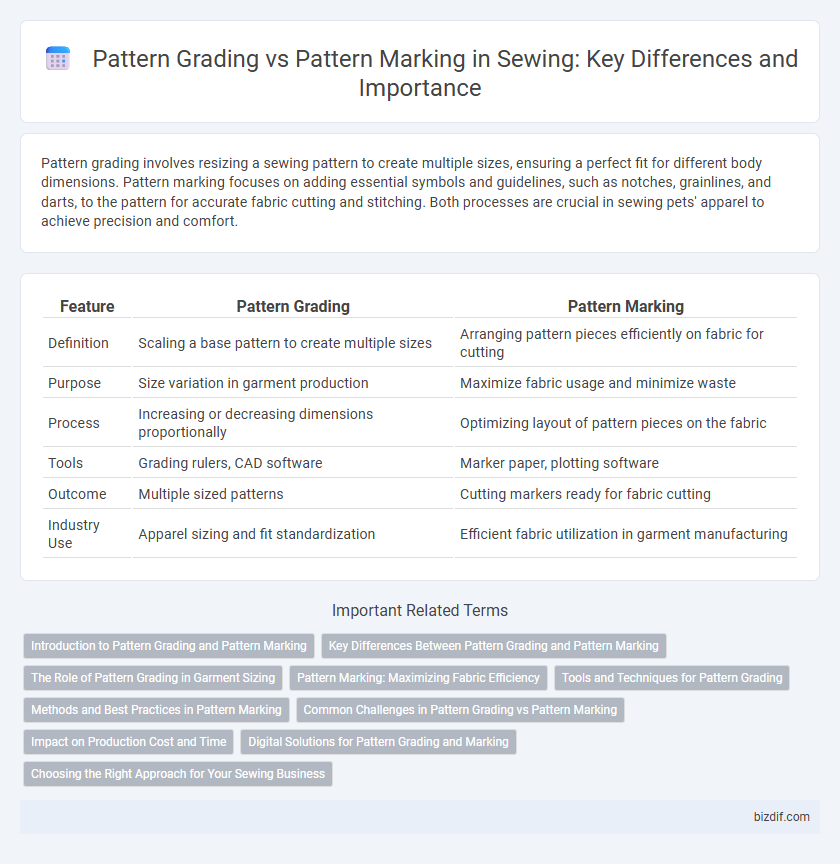

Pattern grading involves resizing a sewing pattern to create multiple sizes, ensuring a perfect fit for different body dimensions. Pattern marking focuses on adding essential symbols and guidelines, such as notches, grainlines, and darts, to the pattern for accurate fabric cutting and stitching. Both processes are crucial in sewing pets' apparel to achieve precision and comfort.

Table of Comparison

| Feature | Pattern Grading | Pattern Marking |

|---|---|---|

| Definition | Scaling a base pattern to create multiple sizes | Arranging pattern pieces efficiently on fabric for cutting |

| Purpose | Size variation in garment production | Maximize fabric usage and minimize waste |

| Process | Increasing or decreasing dimensions proportionally | Optimizing layout of pattern pieces on the fabric |

| Tools | Grading rulers, CAD software | Marker paper, plotting software |

| Outcome | Multiple sized patterns | Cutting markers ready for fabric cutting |

| Industry Use | Apparel sizing and fit standardization | Efficient fabric utilization in garment manufacturing |

Introduction to Pattern Grading and Pattern Marking

Pattern grading involves systematically increasing or decreasing the size of a base pattern to create a range of garment sizes, ensuring consistent fit and proportional scaling across different dimensions. Pattern marking, on the other hand, focuses on transferring specific design elements and cutting instructions onto fabric, including notches, grain lines, and seam allowances, to guide the cutting and sewing process accurately. Both techniques are crucial in garment production, with grading addressing size variations and marking ensuring precise assembly.

Key Differences Between Pattern Grading and Pattern Marking

Pattern grading involves creating different sizes from a base pattern by systematically increasing or decreasing its dimensions to fit various body measurements. Pattern marking, on the other hand, refers to placing pattern pieces accurately on fabric to maximize material usage and ensure correct alignment before cutting. Key differences include grading focusing on size scalability while marking emphasizes fabric layout optimization and cutting precision.

The Role of Pattern Grading in Garment Sizing

Pattern grading plays a crucial role in garment sizing by systematically increasing or decreasing the dimensions of a base pattern to create multiple size variants. This process ensures that clothing fits a wide range of body measurements accurately, maintaining proportionality and design integrity across sizes. Unlike pattern marking, which focuses on placing cutting and sewing guides, pattern grading directly impacts size scalability and production efficiency in garment manufacturing.

Pattern Marking: Maximizing Fabric Efficiency

Pattern marking plays a crucial role in maximizing fabric efficiency by strategically arranging pattern pieces to minimize waste and ensure optimal use of material. Precise marking guides cutting processes, reducing errors and fabric loss while enhancing production speed and cost-effectiveness. Effective pattern marking leverages software tools and expertise to align grainlines, incorporate fabric defects, and accommodate fabric stretch, directly impacting garment quality and sustainability.

Tools and Techniques for Pattern Grading

Pattern grading relies on specialized tools such as grading rulers, curve rulers, and digitizing tablets to accurately scale garment templates across multiple sizes. Techniques involve precise measurements, mathematical calculations, and computer-aided design (CAD) software to maintain proportions and fit consistency during size adjustments. These tools and methods ensure efficient pattern scaling while preserving the original design's integrity and contour lines.

Methods and Best Practices in Pattern Marking

Pattern grading involves systematically increasing or decreasing the size of a base pattern to create a range of sizes, while pattern marking focuses on accurately transferring pattern details onto fabric for cutting and sewing. Best practices in pattern marking include using clear, precise symbols such as notches, drill marks, and grainlines to ensure alignment and construction accuracy, and employing tools like tracing wheels, chalk, or fabric pens to maintain consistency. Utilizing durable and visible markings enhances efficiency and reduces errors during garment assembly.

Common Challenges in Pattern Grading vs Pattern Marking

Pattern grading often faces challenges such as maintaining accurate size increments and preserving garment proportions across multiple sizes, which can lead to fit inconsistencies if not managed properly. Pattern marking struggles with efficient fabric utilization and precise alignment of pattern pieces, increasing the risk of material wastage and production errors. Both processes require meticulous attention to detail to ensure the final garment meets design specifications and quality standards.

Impact on Production Cost and Time

Pattern grading adjusts the size specifications of a sewing pattern, directly affecting production efficiency by enabling mass production across various sizes without creating new patterns, thereby reducing both time and material costs. Pattern marking involves placing pattern pieces on fabric for cutting, influencing fabric utilization and minimizing waste, which lowers raw material expenses and shortens production cycles. Efficient grading streamlines size scalability, while precise marking optimizes fabric use; together, they significantly impact overall production cost and time management in garment manufacturing.

Digital Solutions for Pattern Grading and Marking

Digital solutions for pattern grading enable precise size scaling through automated algorithms, significantly reducing manual errors and production time. Advanced software integrates pattern marking features that optimize fabric utilization by generating accurate marker layouts, minimizing material waste. Combining digital pattern grading with intelligent marking systems enhances manufacturing efficiency and supports sustainable garment production.

Choosing the Right Approach for Your Sewing Business

Pattern grading involves resizing a base pattern to create multiple sizes, ensuring consistent fit across a product line, while pattern marking focuses on placing all the necessary cutting and sewing instructions on fabric for accurate assembly. Choosing the right approach depends on your sewing business scale; grading is essential for mass production and size range expansion, whereas marking is crucial for precise garment construction and minimizing fabric waste. Integrating efficient pattern grading techniques with accurate pattern marking enhances production quality and operational efficiency in clothing manufacturing.

Pattern grading vs Pattern marking Infographic

bizdif.com

bizdif.com