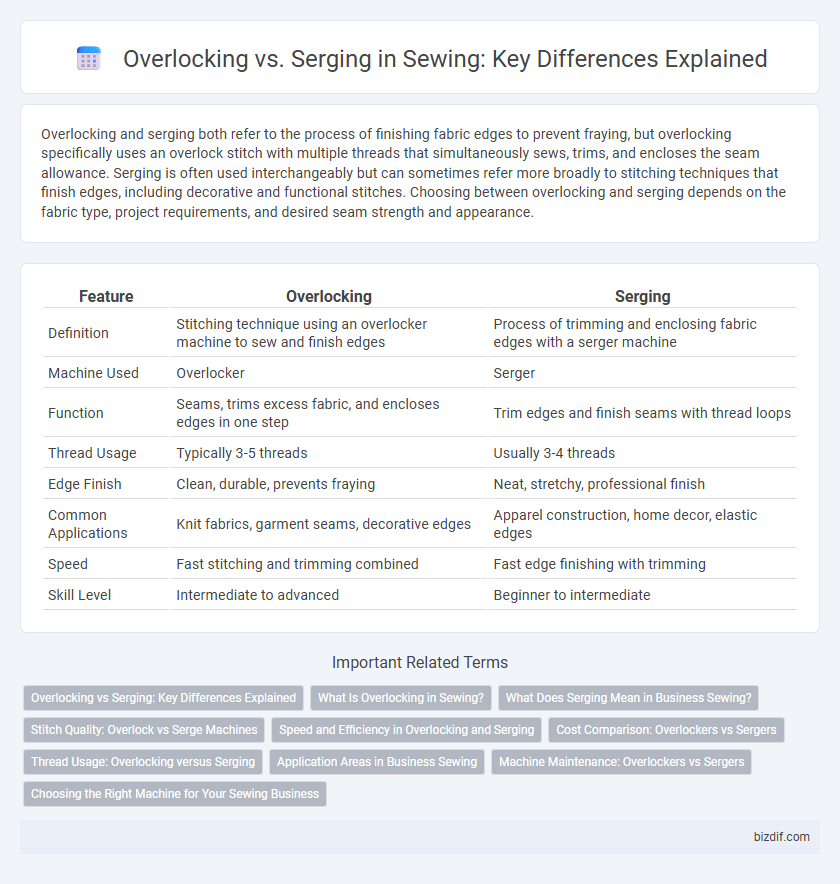

Overlocking and serging both refer to the process of finishing fabric edges to prevent fraying, but overlocking specifically uses an overlock stitch with multiple threads that simultaneously sews, trims, and encloses the seam allowance. Serging is often used interchangeably but can sometimes refer more broadly to stitching techniques that finish edges, including decorative and functional stitches. Choosing between overlocking and serging depends on the fabric type, project requirements, and desired seam strength and appearance.

Table of Comparison

| Feature | Overlocking | Serging |

|---|---|---|

| Definition | Stitching technique using an overlocker machine to sew and finish edges | Process of trimming and enclosing fabric edges with a serger machine |

| Machine Used | Overlocker | Serger |

| Function | Seams, trims excess fabric, and encloses edges in one step | Trim edges and finish seams with thread loops |

| Thread Usage | Typically 3-5 threads | Usually 3-4 threads |

| Edge Finish | Clean, durable, prevents fraying | Neat, stretchy, professional finish |

| Common Applications | Knit fabrics, garment seams, decorative edges | Apparel construction, home decor, elastic edges |

| Speed | Fast stitching and trimming combined | Fast edge finishing with trimming |

| Skill Level | Intermediate to advanced | Beginner to intermediate |

Overlocking vs Serging: Key Differences Explained

Overlocking and serging both finish fabric edges to prevent fraying, but overlocking uses multiple threads to create a durable, stretchy seam ideal for knit fabrics, while serging often refers to a similar stitch with slight regional or brand variations. Overlock machines typically perform trimming and stitching simultaneously, providing a clean edge, whereas sergers emphasize seam strength and neatness for woven or slippery fabrics. Understanding these distinctions is essential for selecting the right technique to enhance garment durability and appearance.

What Is Overlocking in Sewing?

Overlocking in sewing is a finishing technique that uses an overlock machine to stitch over the edge of fabric, preventing fraying and providing a clean, professional look. It typically involves multiple threads looping around the fabric edge, securing seams while trimming excess material simultaneously. Overlocking enhances the durability and stretch of garments, making it essential for knit fabrics and activewear production.

What Does Serging Mean in Business Sewing?

Serging in business sewing refers to the use of a serger machine to trim, stitch, and finish fabric edges simultaneously, creating professional and durable seams. This technique enhances garment quality by preventing fraying and ensuring clean, strong edges that withstand frequent wear and washing. Unlike traditional sewing machines, sergers utilize multiple threads and differential feed to produce stretchable seams ideal for knit fabrics and mass production efficiency.

Stitch Quality: Overlock vs Serge Machines

Overlock machines create strong, durable stitches by looping multiple threads over fabric edges, providing excellent seam finishing and preventing fraying. Serge machines offer similar stitch quality but often produce finer, cleaner edges suitable for lightweight fabrics and detailed garment construction. The choice between overlock and serge machines depends on fabric type and desired stitch appearance, with both delivering professional-quality seam reinforcement.

Speed and Efficiency in Overlocking and Serging

Overlocking machines typically offer faster stitching speeds, often exceeding 1,300 stitches per minute, which enhances productivity in handling large fabric volumes. Serging machines, while similar, may vary slightly in speed but excel in creating clean, finished edges with minimal fabric wastage, contributing to efficient garment production. The combination of high-speed stitching and edge finishing capabilities makes both overlocking and serging essential for time-saving, high-quality sewing projects.

Cost Comparison: Overlockers vs Sergers

Overlockers generally have a lower initial cost compared to sergers, making them a budget-friendly option for beginner sewers. Sergers often feature advanced functionalities such as multiple thread options and cutting mechanisms, justifying their higher price point. Long-term costs also vary as sergers may require more maintenance and expensive replacement parts.

Thread Usage: Overlocking versus Serging

Overlocking typically uses three to five threads, creating a strong and flexible seam suitable for stretch fabrics and knitwear. Serging, often synonymous with overlocking, can also utilize multiple threads but emphasizes finishing raw fabric edges to prevent fraying. The thread count and type in both techniques directly influence seam durability and fabric elasticity in garment construction.

Application Areas in Business Sewing

Overlocking is widely used in garment manufacturing for finishing raw fabric edges and preventing fraying, especially in knitwear and stretch fabrics due to its strong, flexible seam quality. Serging, commonly applied in home sewing and small-scale tailoring businesses, excels in trimming fabric edges while simultaneously stitching, making it ideal for quick seam finishes on lighter materials. Both techniques enhance production efficiency but differ in their compatibility with fabric types and volume requirements in the fashion and textile industries.

Machine Maintenance: Overlockers vs Sergers

Overlockers and sergers require consistent machine maintenance to ensure precise stitching and longevity, including regular cleaning, oiling, and tension adjustments. Overlocker maintenance often involves more frequent blade replacement due to cutting fabric edges, while sergers may need meticulous threading checks to prevent thread jams. Understanding each machine's unique components and maintenance needs is crucial for seamless sewing projects and preventing costly repairs.

Choosing the Right Machine for Your Sewing Business

Choosing the right machine for your sewing business depends on the types of fabrics and projects you handle regularly. Overlock machines excel at finishing raw edges and creating strong seams quickly, ideal for knit and stretch fabrics, while sergers provide versatile stitch options and can trim excess fabric automatically, enhancing efficiency in mass production. Evaluating your business needs for speed, stitch variety, and fabric compatibility ensures you invest in a machine that maximizes productivity and garment quality.

Overlocking vs Serging Infographic

bizdif.com

bizdif.com