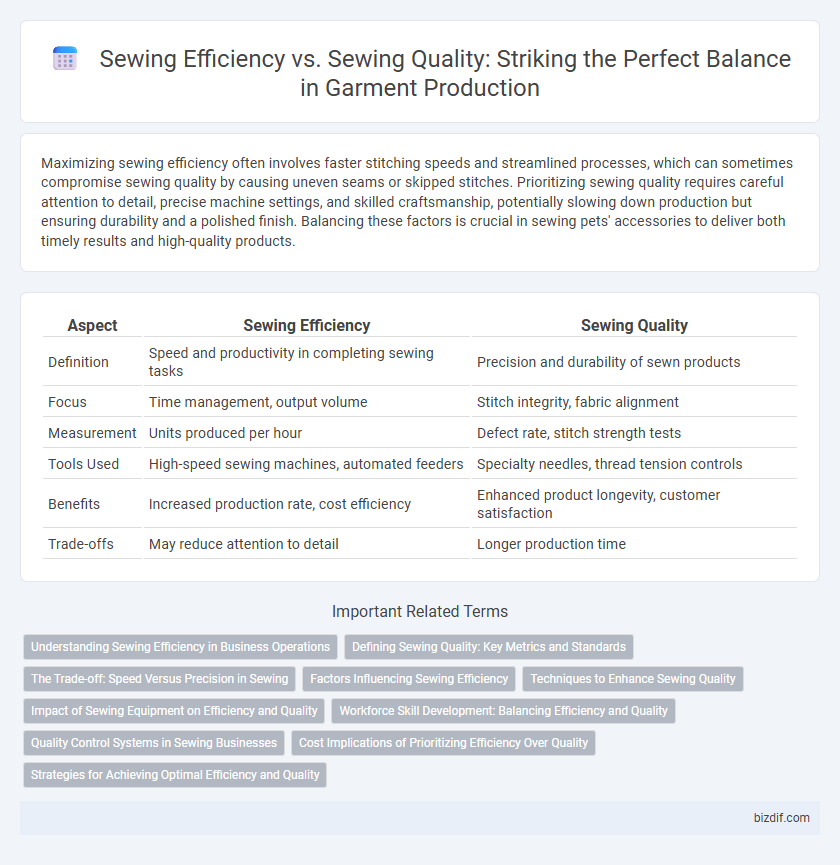

Maximizing sewing efficiency often involves faster stitching speeds and streamlined processes, which can sometimes compromise sewing quality by causing uneven seams or skipped stitches. Prioritizing sewing quality requires careful attention to detail, precise machine settings, and skilled craftsmanship, potentially slowing down production but ensuring durability and a polished finish. Balancing these factors is crucial in sewing pets' accessories to deliver both timely results and high-quality products.

Table of Comparison

| Aspect | Sewing Efficiency | Sewing Quality |

|---|---|---|

| Definition | Speed and productivity in completing sewing tasks | Precision and durability of sewn products |

| Focus | Time management, output volume | Stitch integrity, fabric alignment |

| Measurement | Units produced per hour | Defect rate, stitch strength tests |

| Tools Used | High-speed sewing machines, automated feeders | Specialty needles, thread tension controls |

| Benefits | Increased production rate, cost efficiency | Enhanced product longevity, customer satisfaction |

| Trade-offs | May reduce attention to detail | Longer production time |

Understanding Sewing Efficiency in Business Operations

Sewing efficiency in business operations hinges on optimizing machine performance and workforce skills to maximize output without compromising quality. Precise thread tension, stitch consistency, and fabric handling directly impact product durability and customer satisfaction. Balancing operational speed with meticulous quality checks ensures a competitive advantage in the garment manufacturing industry.

Defining Sewing Quality: Key Metrics and Standards

Sewing quality is defined by key metrics such as stitch consistency, seam strength, and fabric compatibility, which ensure durability and aesthetic appeal. Standards set by organizations like the ASTM and ISO provide measurable criteria for thread tension, seam allowance accuracy, and stitch density. Prioritizing these quality indicators leads to superior garment performance, minimizing defects while maintaining production efficiency.

The Trade-off: Speed Versus Precision in Sewing

Sewing efficiency often demands higher speed, which can compromise stitching precision and overall garment quality. Achieving superior sewing quality requires meticulous attention to detail and slower, controlled stitching, reducing production throughput. Balancing the trade-off between speed and precision is crucial for manufacturers aiming to optimize both productivity and finished product excellence.

Factors Influencing Sewing Efficiency

Sewing efficiency is heavily influenced by machine speed, operator skill level, and fabric type, each contributing to the overall production rate. Proper maintenance of sewing equipment and ergonomic workstation design reduce downtime and operator fatigue, enhancing efficiency without compromising sewing quality. Balancing stitch precision and speed ensures that higher output does not sacrifice the durability or appearance of the finished garment.

Techniques to Enhance Sewing Quality

Implementing precise stitch alignment and maintaining consistent thread tension are crucial techniques to enhance sewing quality while minimizing errors. Utilizing specialized presser feet and high-quality needles tailored to fabric types improves stitch accuracy and fabric integrity. Regular machine maintenance and selecting appropriate stitch types further optimize sewing efficiency without compromising the overall finish.

Impact of Sewing Equipment on Efficiency and Quality

High-quality sewing equipment significantly enhances sewing efficiency by reducing downtime and minimizing fabric waste through precise stitching mechanisms. Advanced machines with automated features improve stitch consistency, directly impacting garment quality and durability. Investing in ergonomic and technologically sophisticated sewing tools optimizes production speed without compromising the finished product's craftsmanship.

Workforce Skill Development: Balancing Efficiency and Quality

Workforce skill development significantly enhances sewing quality by reducing errors and improving craftsmanship, which ultimately leads to higher customer satisfaction. Investing in comprehensive training programs elevates sewing efficiency by enabling workers to perform precise tasks faster, minimizing material waste and rework. Balancing efficiency and quality through targeted skill enhancement drives production excellence and sustains competitive advantage in the garment industry.

Quality Control Systems in Sewing Businesses

Implementing advanced quality control systems in sewing businesses significantly enhances sewing efficiency by minimizing defects and rework time. Automated inspection technologies and real-time monitoring enable early detection of errors, ensuring consistent garment quality without compromising production speed. Prioritizing quality control fosters customer satisfaction and reduces production costs, creating a competitive advantage in the apparel industry.

Cost Implications of Prioritizing Efficiency Over Quality

Prioritizing sewing efficiency often reduces production time and labor costs but may lead to increased defect rates and higher returns or repairs expenses, negatively impacting overall profitability. Poor stitch quality can result in garment failures, decreasing customer satisfaction and brand reputation, which incurs long-term financial losses. Balancing sewing speed with quality controls is crucial to minimizing waste and costly rework while maintaining product standards.

Strategies for Achieving Optimal Efficiency and Quality

Balancing sewing efficiency and quality requires implementing precision machinery paired with skilled operators, ensuring consistent stitch integrity and fabric handling. Utilizing advanced training programs enhances worker proficiency, reducing errors and rework while maintaining high production speeds. Adopting streamlined workflow layouts and real-time quality monitoring systems enables immediate adjustments, optimizing output without compromising garment durability or finish.

Sewing efficiency vs Sewing quality Infographic

bizdif.com

bizdif.com