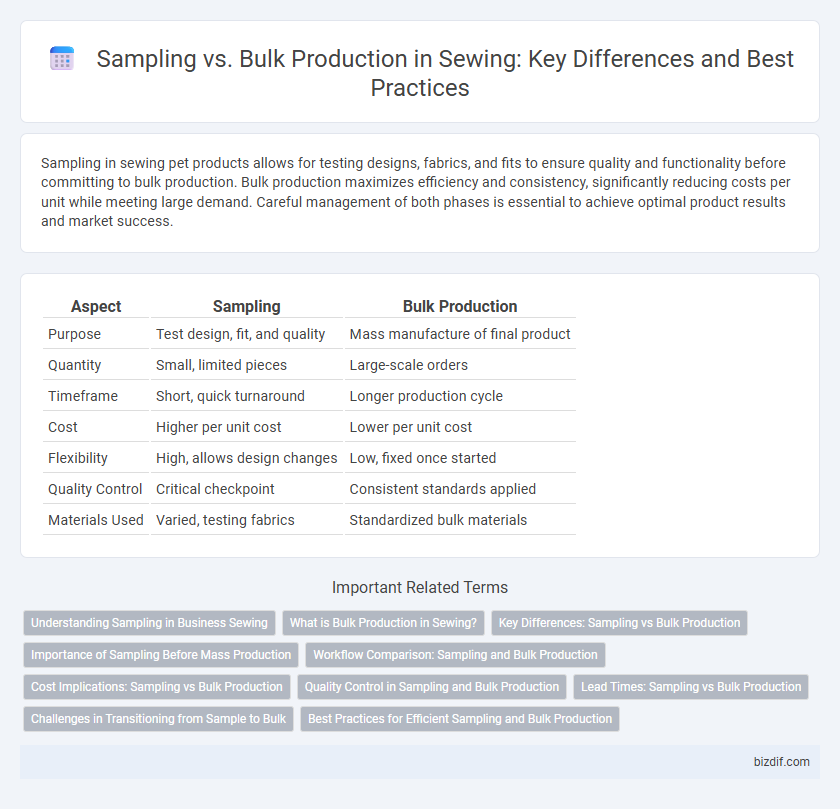

Sampling in sewing pet products allows for testing designs, fabrics, and fits to ensure quality and functionality before committing to bulk production. Bulk production maximizes efficiency and consistency, significantly reducing costs per unit while meeting large demand. Careful management of both phases is essential to achieve optimal product results and market success.

Table of Comparison

| Aspect | Sampling | Bulk Production |

|---|---|---|

| Purpose | Test design, fit, and quality | Mass manufacture of final product |

| Quantity | Small, limited pieces | Large-scale orders |

| Timeframe | Short, quick turnaround | Longer production cycle |

| Cost | Higher per unit cost | Lower per unit cost |

| Flexibility | High, allows design changes | Low, fixed once started |

| Quality Control | Critical checkpoint | Consistent standards applied |

| Materials Used | Varied, testing fabrics | Standardized bulk materials |

Understanding Sampling in Business Sewing

Sampling in business sewing involves creating prototype garments to test design, fit, and construction before mass production. This process helps identify potential issues early, ensuring quality control and reducing costly errors in bulk production. Efficient sampling boosts accuracy in measurements, fabric choices, and sewing techniques, optimizing the entire production workflow.

What is Bulk Production in Sewing?

Bulk production in sewing refers to the large-scale manufacturing process where garments or textile products are produced in high volumes following finalized designs and approved samples. This phase emphasizes efficiency, cost-effectiveness, and consistency in quality to meet market demand and delivery deadlines. Factories employ automated machinery and standardized workflows to optimize output and reduce production time during bulk orders.

Key Differences: Sampling vs Bulk Production

Sampling in sewing involves creating a small, detailed prototype to test design, fit, and fabric quality before mass manufacturing. Bulk production focuses on high-volume garment manufacturing, emphasizing efficiency, cost-effectiveness, and consistency across thousands of units. Key differences include scale, cost per unit, and purpose, with sampling prioritizing evaluation and bulk production targeting final product delivery.

Importance of Sampling Before Mass Production

Sampling before bulk production in sewing ensures quality control by identifying design flaws, fabric issues, and sizing errors early. This step minimizes costly mistakes, reduces waste, and increases customer satisfaction by delivering consistent, well-finished garments. Accurate samples provide a tangible reference for production teams, streamlining workflow and maintaining brand standards across large orders.

Workflow Comparison: Sampling and Bulk Production

Sampling in sewing involves creating prototype garments to test design, fit, and fabric before mass production, allowing for adjustments and quality control. Bulk production follows a highly efficient workflow with standardized processes, large-scale fabric cutting, sewing assembly lines, and quality inspections to ensure consistency and meet demand. Workflow differences highlight the iterative, detail-focused nature of sampling versus the streamlined, volume-driven approach in bulk production.

Cost Implications: Sampling vs Bulk Production

Sampling in sewing involves producing a limited number of prototypes to test design accuracy and material quality, which incurs higher per-unit costs due to small quantities and detailed craftsmanship. Bulk production significantly reduces the cost per unit by leveraging economies of scale, standardized processes, and bulk purchasing of materials, making it more cost-effective for large orders. Understanding the cost implications of sampling versus bulk production is crucial for balancing initial investment risks with overall production efficiency in garment manufacturing.

Quality Control in Sampling and Bulk Production

Quality control in sampling ensures early detection of defects, allowing adjustments to design and process before large-scale production begins. Bulk production quality control focuses on maintaining consistency across thousands of units by implementing standardized inspections and using statistical process control techniques. Effective quality management in both stages minimizes waste, reduces costs, and guarantees final product standards meet customer expectations.

Lead Times: Sampling vs Bulk Production

Sampling in sewing typically requires shorter lead times, ranging from a few days to two weeks, as it involves creating prototypes or small batches for design approval and quality checks. Bulk production lead times are significantly longer, often spanning several weeks to months, due to the large volume of garments, detailed planning, and coordination needed to ensure consistent quality and meet order deadlines. Efficient management of sampling and bulk production timelines is critical to streamline the overall garment manufacturing process and reduce time-to-market.

Challenges in Transitioning from Sample to Bulk

Transitioning from sample sewing to bulk production often reveals challenges such as maintaining consistent garment quality due to variations in fabric and workmanship. Scaling up requires precise pattern grading and efficient allocation of labor to avoid discrepancies and production delays. Managing supply chain logistics becomes crucial to ensure timely delivery and cost control during mass manufacturing.

Best Practices for Efficient Sampling and Bulk Production

Efficient sampling in sewing involves creating accurate prototypes using consistent materials and precise measurements to identify potential issues before bulk production. Bulk production benefits from streamlined workflows, standardized quality control protocols, and effective communication between design and manufacturing teams to minimize errors and reduce lead times. Prioritizing detailed sample evaluations and clear production guidelines ensures smoother transitions from prototypes to mass-produced garments.

Sampling vs Bulk production Infographic

bizdif.com

bizdif.com