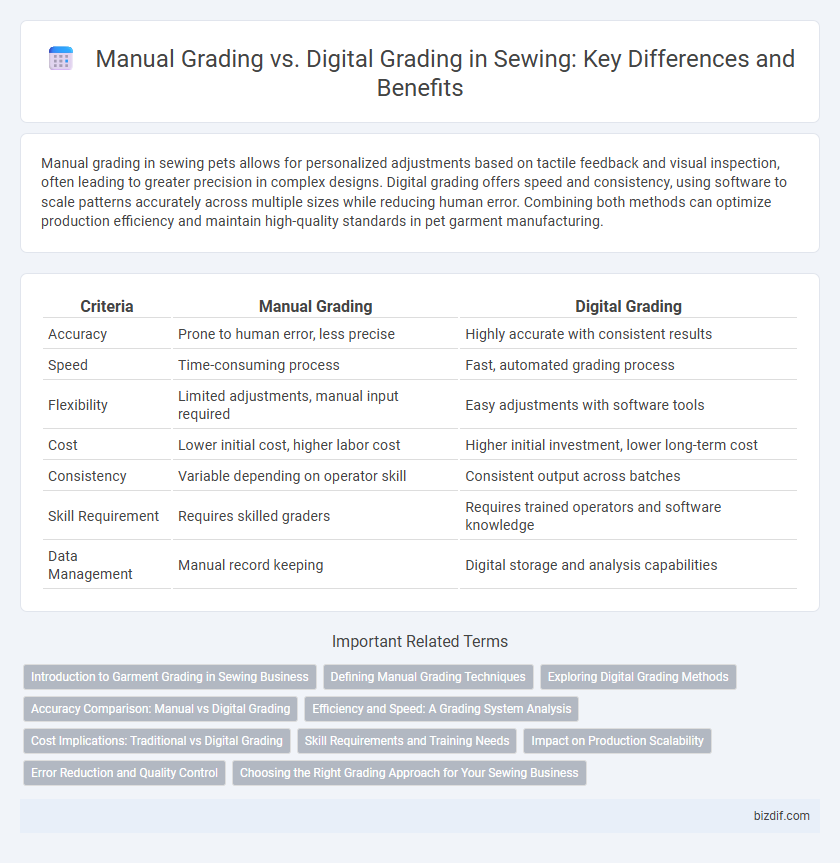

Manual grading in sewing pets allows for personalized adjustments based on tactile feedback and visual inspection, often leading to greater precision in complex designs. Digital grading offers speed and consistency, using software to scale patterns accurately across multiple sizes while reducing human error. Combining both methods can optimize production efficiency and maintain high-quality standards in pet garment manufacturing.

Table of Comparison

| Criteria | Manual Grading | Digital Grading |

|---|---|---|

| Accuracy | Prone to human error, less precise | Highly accurate with consistent results |

| Speed | Time-consuming process | Fast, automated grading process |

| Flexibility | Limited adjustments, manual input required | Easy adjustments with software tools |

| Cost | Lower initial cost, higher labor cost | Higher initial investment, lower long-term cost |

| Consistency | Variable depending on operator skill | Consistent output across batches |

| Skill Requirement | Requires skilled graders | Requires trained operators and software knowledge |

| Data Management | Manual record keeping | Digital storage and analysis capabilities |

Introduction to Garment Grading in Sewing Business

Garment grading in sewing business involves scaling patterns to create different sizes, crucial for consistent fit and efficient production. Manual grading relies on hand measurements and adjustments, often leading to variations and longer turnaround times. Digital grading uses computer software to precisely resize patterns, enhancing accuracy, reducing errors, and accelerating the production process.

Defining Manual Grading Techniques

Manual grading techniques rely on traditional methods where patterns are adjusted by hand using rulers, grading sticks, and measuring tapes to incrementally alter sizes. This process demands skillful interpretation of size specifications to ensure accuracy across garments, often involving physical marking on paper or fabric. Manual grading is favored in bespoke tailoring and small-scale production for its tactile precision and flexibility in customizing patterns.

Exploring Digital Grading Methods

Digital grading methods in sewing utilize advanced software to create precise size variations from a base pattern, enhancing accuracy and consistency compared to manual grading. These systems reduce human error and save time by automating measurement adjustments across multiple garment sizes, improving production efficiency. Integration with computer-aided design (CAD) tools allows seamless pattern modifications and faster iteration cycles, crucial for modern apparel manufacturing.

Accuracy Comparison: Manual vs Digital Grading

Digital grading offers superior accuracy over manual grading by utilizing precise algorithms that minimize human error in pattern adjustments. Manual grading relies heavily on the grader's experience and can introduce inconsistencies, especially in complex size variations. Enhanced digital tools ensure consistent measurements and scalability, significantly improving production efficiency in sewing industries.

Efficiency and Speed: A Grading System Analysis

Manual grading in sewing relies heavily on human skill and experience, often resulting in slower pattern adjustments and increased margin for error during the size differentiation process. Digital grading systems enhance efficiency by automating complex calculations, enabling rapid and precise size scaling with minimal human intervention, which significantly reduces production time. The integration of CAD software in digital grading streamlines workflow, allowing for faster iteration, consistent accuracy across sizes, and scalable output that outperforms traditional manual methods.

Cost Implications: Traditional vs Digital Grading

Manual grading in sewing often incurs higher labor costs due to time-intensive pattern adjustments and greater risk of human error, leading to material wastage and rework expenses. Digital grading utilizes automated software to streamline pattern scaling, significantly reducing labor hours while enhancing accuracy and consistency, which lowers overall production costs. Investment in digital grading technology may require upfront capital, but long-term savings from improved efficiency and reduced errors offer a more cost-effective solution compared to traditional methods.

Skill Requirements and Training Needs

Manual grading in sewing demands strong visual assessment skills and hands-on experience to accurately adjust pattern sizes, often requiring extensive training through apprenticeships or on-the-job practice. Digital grading, however, relies on proficiency with specialized software such as CAD systems, necessitating formal training in computer-aided design and technical pattern-making. Mastery of digital tools reduces errors and increases efficiency but requires continuous skill development to keep pace with evolving technology in apparel manufacturing.

Impact on Production Scalability

Manual grading limits production scalability due to its time-consuming process and susceptibility to human error, resulting in inconsistent garment sizing and increased material waste. Digital grading automates size adjustments with precision, accelerating workflow and enabling faster adaptation to size variations across different markets. Integration of digital grading software boosts overall production efficiency and supports large-scale manufacturing demands while maintaining quality standards.

Error Reduction and Quality Control

Manual grading in sewing often leads to higher error rates due to inconsistent measurements and human fatigue, impacting overall garment quality. Digital grading systems utilize precise algorithms and standardized measurements, significantly reducing errors and ensuring uniformity across sizes. Enhanced accuracy in digital grading improves quality control by maintaining strict adherence to design specifications and minimizing costly production mistakes.

Choosing the Right Grading Approach for Your Sewing Business

Manual grading offers hands-on control and flexibility with pattern adjustments, making it ideal for bespoke or small-batch sewing businesses that require custom precision. Digital grading provides increased speed, accuracy, and consistency, benefiting larger operations that need to scale production efficiently while minimizing errors. Selecting the right grading approach depends on your business size, production volume, and specific needs for customization versus automation.

Manual grading vs digital grading Infographic

bizdif.com

bizdif.com