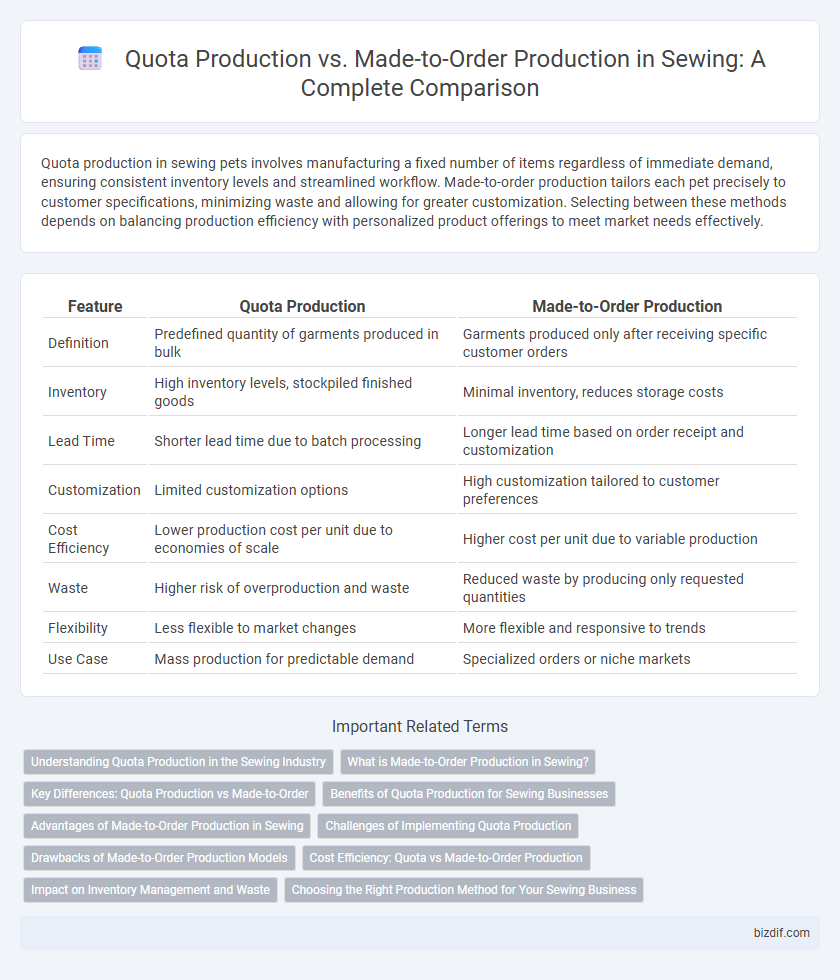

Quota production in sewing pets involves manufacturing a fixed number of items regardless of immediate demand, ensuring consistent inventory levels and streamlined workflow. Made-to-order production tailors each pet precisely to customer specifications, minimizing waste and allowing for greater customization. Selecting between these methods depends on balancing production efficiency with personalized product offerings to meet market needs effectively.

Table of Comparison

| Feature | Quota Production | Made-to-Order Production |

|---|---|---|

| Definition | Predefined quantity of garments produced in bulk | Garments produced only after receiving specific customer orders |

| Inventory | High inventory levels, stockpiled finished goods | Minimal inventory, reduces storage costs |

| Lead Time | Shorter lead time due to batch processing | Longer lead time based on order receipt and customization |

| Customization | Limited customization options | High customization tailored to customer preferences |

| Cost Efficiency | Lower production cost per unit due to economies of scale | Higher cost per unit due to variable production |

| Waste | Higher risk of overproduction and waste | Reduced waste by producing only requested quantities |

| Flexibility | Less flexible to market changes | More flexible and responsive to trends |

| Use Case | Mass production for predictable demand | Specialized orders or niche markets |

Understanding Quota Production in the Sewing Industry

Quota production in the sewing industry involves setting specific output targets for workers or teams to ensure consistent productivity and meet bulk order demands efficiently. This method emphasizes uniformity, speed, and volume, often leading to standardized garment quality and reduced lead times in mass production environments. Understanding quota production helps manufacturers balance workforce motivation with operational efficiency while controlling production costs.

What is Made-to-Order Production in Sewing?

Made-to-Order Production in sewing refers to a manufacturing process where garments are created only after a customer places a specific order, minimizing inventory and reducing waste. This method allows for high customization, tailoring each piece to exact measurements and design preferences, enhancing product uniqueness. It contrasts with quota production by focusing on demand-driven efficiency and personalized output rather than mass production targets.

Key Differences: Quota Production vs Made-to-Order

Quota production relies on setting a predetermined number of units to be sewn within a specific timeframe, optimizing efficiency and cost control in mass manufacturing. Made-to-order production customizes each garment based on individual customer specifications, minimizing inventory and reducing waste by producing only what is requested. The key difference lies in quota production's emphasis on volume and standardization versus made-to-order's focus on flexibility and personalization.

Benefits of Quota Production for Sewing Businesses

Quota production in sewing businesses ensures consistent output, helping manufacturers meet market demand reliably while optimizing resource allocation. This production method facilitates better inventory management and cost control by forecasting the number of garments to be produced within a specific timeframe. Maintaining a steady workflow through quota production improves labor efficiency and reduces downtime, ultimately boosting overall profitability in the sewing industry.

Advantages of Made-to-Order Production in Sewing

Made-to-order production in sewing offers significant advantages such as reduced inventory costs and minimized fabric waste by producing garments only upon customer request. This method enhances customization, allowing precise adjustments to size, style, and materials, thereby increasing customer satisfaction and loyalty. Furthermore, made-to-order production accelerates response to market trends, enabling manufacturers to adapt quickly to changing consumer preferences and reduce the risk of overproduction.

Challenges of Implementing Quota Production

Quota production in sewing faces significant challenges including the risk of reduced garment quality due to rushed work, increased worker fatigue, and difficulty in maintaining consistent output rates. This system demands precise coordination and monitoring to avoid production bottlenecks and high defect rates, especially when quotas are set too rigidly without considering operator skill levels. Balancing speed and craftsmanship remains a critical issue, often leading to compromised product standards and worker dissatisfaction.

Drawbacks of Made-to-Order Production Models

Made-to-order production models in sewing often face challenges such as longer lead times and higher production costs due to the customization required for each order. The variability in demand complicates inventory management, leading to potential delays and inefficiencies in workflow. Limited economies of scale restrict profitability compared to quota production, which benefits from bulk processing and standardized output.

Cost Efficiency: Quota vs Made-to-Order Production

Quota production enables economies of scale by producing large batches of standardized garments, significantly lowering per-unit costs due to bulk purchasing and streamlined processes. Made-to-order production, although more flexible and responsive to individual customer demands, often incurs higher costs per unit because of limited batch sizes and frequent changeovers. Cost efficiency in quota production makes it ideal for mass-market sewing operations seeking volume-driven profit margins.

Impact on Inventory Management and Waste

Quota production in sewing requires producing fixed quantities regardless of immediate demand, leading to higher inventory levels and increased risk of unsold stock, which contributes to waste. Made-to-order production aligns output directly with customer demand, minimizing excess inventory and significantly reducing fabric and resource waste. Efficient inventory management under made-to-order systems enhances sustainability and lowers storage costs by preventing overproduction.

Choosing the Right Production Method for Your Sewing Business

Quota production maximizes efficiency by producing standardized garments in large volumes, ideal for businesses targeting mass markets and cost reduction through economies of scale. Made-to-order production emphasizes customization and flexibility, catering to niche markets with unique designs and reducing inventory risks by producing only upon customer demand. Selecting the right production method depends on your business goals, target audience, and ability to manage inventory and lead times effectively.

Quota Production vs Made-to-Order Production Infographic

bizdif.com

bizdif.com