Batch production in sewing pets offers efficiency and cost-effectiveness by producing multiple identical items simultaneously, ideal for standardized products like collars and simple outfits. Custom tailoring ensures a perfect fit and unique design tailored to each pet's specific measurements and personality, enhancing comfort and style. Choosing between batch production and custom tailoring depends on the priority of mass availability versus personalized craftsmanship.

Table of Comparison

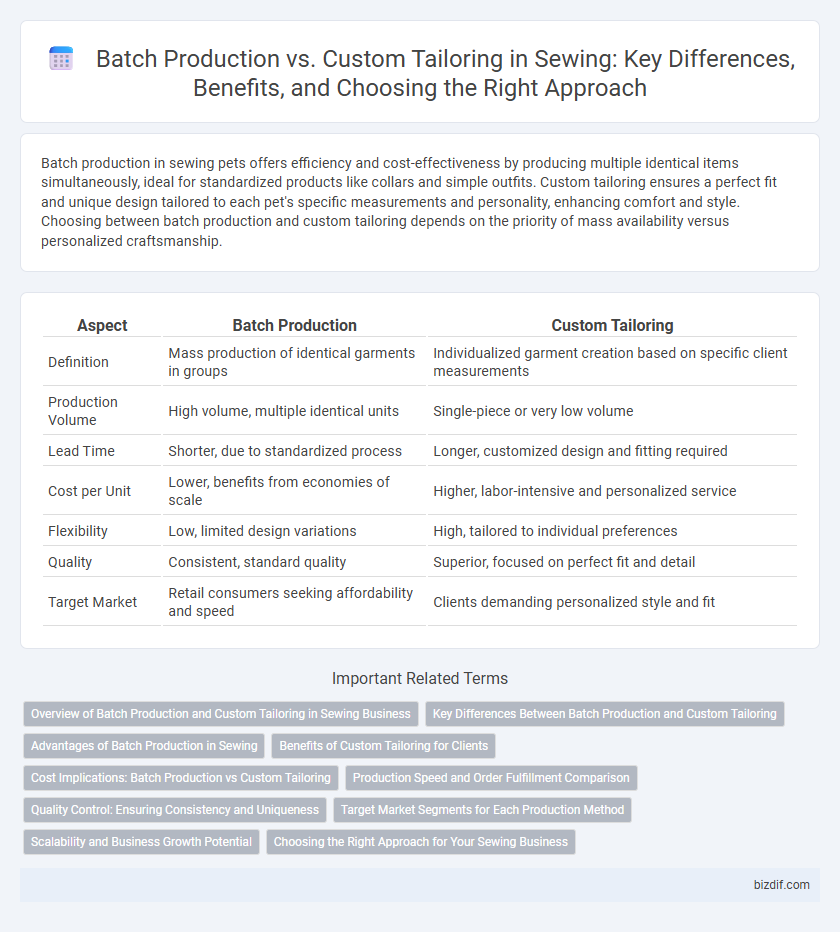

| Aspect | Batch Production | Custom Tailoring |

|---|---|---|

| Definition | Mass production of identical garments in groups | Individualized garment creation based on specific client measurements |

| Production Volume | High volume, multiple identical units | Single-piece or very low volume |

| Lead Time | Shorter, due to standardized process | Longer, customized design and fitting required |

| Cost per Unit | Lower, benefits from economies of scale | Higher, labor-intensive and personalized service |

| Flexibility | Low, limited design variations | High, tailored to individual preferences |

| Quality | Consistent, standard quality | Superior, focused on perfect fit and detail |

| Target Market | Retail consumers seeking affordability and speed | Clients demanding personalized style and fit |

Overview of Batch Production and Custom Tailoring in Sewing Business

Batch production in sewing involves creating multiple identical garments simultaneously, optimizing efficiency and cost-effectiveness for larger orders by using standardized patterns and processes. Custom tailoring, on the other hand, focuses on producing unique, made-to-measure garments tailored specifically to individual client specifications, ensuring high precision and personalization. While batch production suits mass-market demands, custom tailoring excels in delivering bespoke quality and fit for niche clientele.

Key Differences Between Batch Production and Custom Tailoring

Batch production in sewing involves creating multiple identical garments simultaneously, optimizing efficiency and reducing costs through standardized patterns and automated processes. Custom tailoring focuses on individual garment creation tailored to specific measurements and client preferences, resulting in higher precision and personalized fit. The key differences lie in production volume, customization level, turnaround time, and cost efficiency, with batch production suited for mass market demand and custom tailoring prioritizing bespoke quality.

Advantages of Batch Production in Sewing

Batch production in sewing offers consistent quality and faster turnaround times by producing multiple garments simultaneously, reducing setup and labor costs per unit. This method enhances efficiency through standardized patterns and processes, minimizing fabric waste and enabling bulk purchasing of materials for cost savings. It is ideal for meeting large order volumes while maintaining uniformity in design and fit.

Benefits of Custom Tailoring for Clients

Custom tailoring offers personalized fit and unique design choices that enhance comfort and style, ensuring garments perfectly match individual body measurements and preferences. Clients benefit from high-quality materials and meticulous craftsmanship, resulting in durable, long-lasting clothing tailored to their lifestyle. Custom tailoring also allows for exclusive alterations and adjustments, providing flexibility unmatched by batch production methods.

Cost Implications: Batch Production vs Custom Tailoring

Batch production reduces unit costs through economies of scale by producing large quantities of identical garments, making it cost-effective for standardized designs. Custom tailoring incurs higher costs due to individualized measurements, specialized labor, and longer production times, which directly impact pricing. The choice between batch production and custom tailoring depends on balancing production efficiency and personalized garment fit within budget constraints.

Production Speed and Order Fulfillment Comparison

Batch production in sewing enables faster production speed by processing multiple identical garments simultaneously, optimizing machinery and labor efficiency. Custom tailoring involves slower production due to individualized measurements and design adjustments, resulting in longer lead times. Order fulfillment in batch production is quicker for large quantities, while custom tailoring excels in delivering personalized garments with precise fit but requires more time per order.

Quality Control: Ensuring Consistency and Uniqueness

Batch production in sewing emphasizes standardized quality control processes to maintain consistency across large quantities of garments, utilizing automated inspections and uniform material sourcing. Custom tailoring prioritizes individual craftsmanship and meticulous quality checks, ensuring each piece's uniqueness and perfect fit tailored to specific client measurements. Balancing these approaches, quality control systems adapt to either repetitive precision or bespoke detail, optimizing garment excellence in mass or individualized production.

Target Market Segments for Each Production Method

Batch production in sewing targets mass-market segments such as ready-to-wear retailers and large apparel brands seeking consistent quality and economies of scale. Custom tailoring caters to niche markets, including individual clients and luxury consumers prioritizing personalized fit, unique design, and premium craftsmanship. Understanding these distinct target market segments enables businesses to align production methods with consumer demand and optimize resource allocation.

Scalability and Business Growth Potential

Batch production in sewing enables scalability through standardized processes and bulk fabric procurement, significantly reducing per-unit costs and speeding up delivery times, which supports rapid business growth. Custom tailoring offers highly personalized garments, attracting a niche market willing to pay premium prices, but it limits scalability due to the intensive labor and time requirements per order. Businesses aiming for expansion prioritize batch production for higher output and consistent quality, while custom tailoring fosters brand loyalty and reputation within a smaller, specialized client base.

Choosing the Right Approach for Your Sewing Business

Batch production enables sewing businesses to maximize efficiency and reduce costs by producing large quantities of standardized garments, ideal for meeting high market demand. Custom tailoring offers personalized fit and unique design options, attracting clients seeking bespoke, high-quality pieces and allowing higher profit margins per item. Selecting the right approach depends on target audience preferences, production capacity, and desired brand positioning within the fashion industry.

Batch production vs Custom tailoring Infographic

bizdif.com

bizdif.com