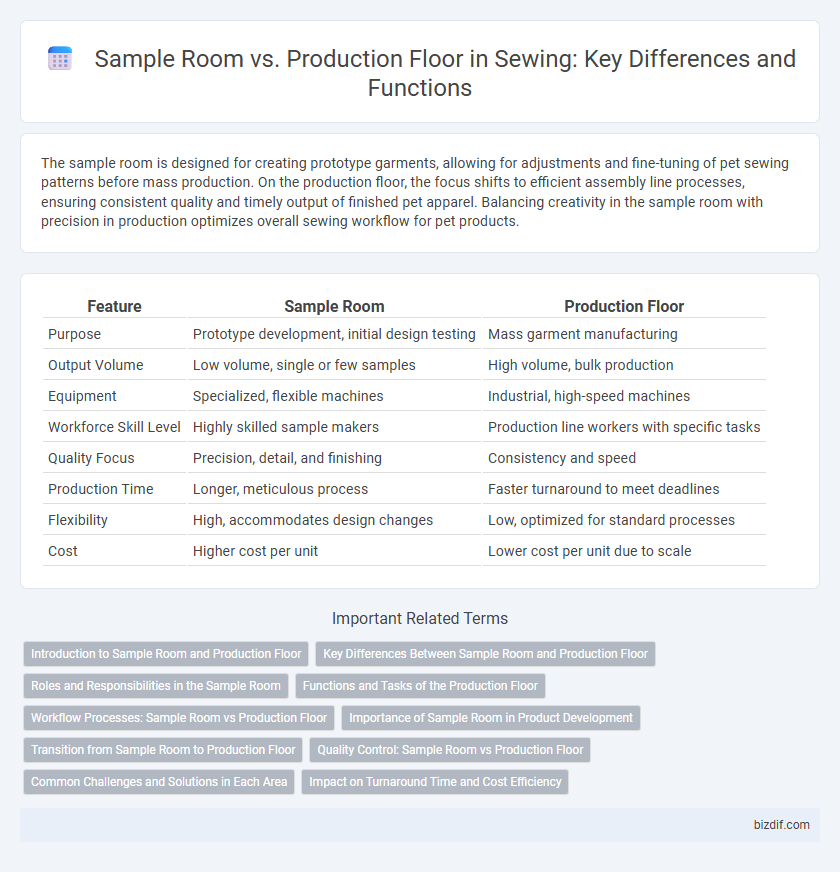

The sample room is designed for creating prototype garments, allowing for adjustments and fine-tuning of pet sewing patterns before mass production. On the production floor, the focus shifts to efficient assembly line processes, ensuring consistent quality and timely output of finished pet apparel. Balancing creativity in the sample room with precision in production optimizes overall sewing workflow for pet products.

Table of Comparison

| Feature | Sample Room | Production Floor |

|---|---|---|

| Purpose | Prototype development, initial design testing | Mass garment manufacturing |

| Output Volume | Low volume, single or few samples | High volume, bulk production |

| Equipment | Specialized, flexible machines | Industrial, high-speed machines |

| Workforce Skill Level | Highly skilled sample makers | Production line workers with specific tasks |

| Quality Focus | Precision, detail, and finishing | Consistency and speed |

| Production Time | Longer, meticulous process | Faster turnaround to meet deadlines |

| Flexibility | High, accommodates design changes | Low, optimized for standard processes |

| Cost | Higher cost per unit | Lower cost per unit due to scale |

Introduction to Sample Room and Production Floor

The Sample Room is a controlled environment where prototypes and garment samples are created to test design concepts, fabric behavior, and fit before mass production begins. It emphasizes precision and quality to ensure that the final product meets design specifications and customer expectations. The Production Floor, in contrast, is a large-scale manufacturing space where approved samples are replicated through assembly line processes to achieve efficiency and high-volume output.

Key Differences Between Sample Room and Production Floor

The sample room in sewing is dedicated to prototyping and creating initial garment samples, emphasizing precision, design adjustments, and testing fabric and fit. In contrast, the production floor focuses on mass garment manufacturing with streamlined processes, higher efficiency, and quality control to meet volume targets. Key differences include workflow speed, worker specialization, and equipment usage tailored for small-scale sample creation versus large-scale production output.

Roles and Responsibilities in the Sample Room

The Sample Room functions as a critical hub for creating prototypes and conducting quality checks before mass production, ensuring design specifications are accurately translated into tangible garments. Technicians and sample makers in the Sample Room collaborate closely with designers to refine patterns, test fabrics, and troubleshoot fit issues, directly influencing the final product. Their precise role involves validating materials, perfecting garment construction, and providing feedback to streamline the production process on the factory floor.

Functions and Tasks of the Production Floor

The production floor in sewing is the central area where bulk garment manufacturing takes place, focusing on tasks such as cutting, stitching, assembling, and quality control. Operators handle specialized machines to ensure consistent fabric handling, seam accuracy, and efficient workflow to meet production targets. This environment emphasizes speed, precision, and coordination among workers to transform samples into finalized products ready for distribution.

Workflow Processes: Sample Room vs Production Floor

The Sample Room workflow involves meticulous prototype creation, pattern testing, and material evaluation to finalize garment designs before mass production. The Production Floor workflow focuses on streamlined assembly line operations, including fabric cutting, sewing, quality control, and packaging to ensure efficient high-volume garment manufacturing. Optimizing communication between these areas reduces errors and accelerates the transition from sample approval to full-scale production.

Importance of Sample Room in Product Development

The sample room plays a crucial role in product development by serving as the testing ground for design concepts, fabric selection, and fit adjustments, ensuring the final garment meets quality standards before mass production. It enables rapid prototyping and iterative refinement, reducing costly errors on the production floor and accelerating time-to-market. Effective collaboration between the sample room and production floor minimizes material waste and optimizes resource allocation throughout the sewing process.

Transition from Sample Room to Production Floor

The transition from the sample room to the production floor involves converting a finalized prototype into scalable manufacturing processes, ensuring consistency in stitch quality and garment fit. Detailed specifications and tech packs created during the sample development are critical for maintaining adherence to design standards throughout bulk production. Efficient communication between sample makers and production staff minimizes errors and accelerates the production timeline while optimizing fabric utilization and machine settings.

Quality Control: Sample Room vs Production Floor

Quality control in the sample room ensures prototype garments meet design specifications and fit standards before mass production begins, focusing on precision and material integrity. On the production floor, quality control emphasizes consistency and defect prevention across large volumes, using real-time inspection and process monitoring. Both environments employ different metrics and tools to balance innovation with scalability in garment manufacturing.

Common Challenges and Solutions in Each Area

Sample rooms often face challenges like fabric wastage and frequent design alterations that disrupt workflow, requiring precise pattern making and effective communication between designers and tailors. Production floors struggle with maintaining consistent quality and meeting high-volume deadlines, which calls for streamlined assembly line processes and rigorous quality control measures. Implementing digital tracking systems and regular cross-departmental training helps both areas reduce errors and improve efficiency.

Impact on Turnaround Time and Cost Efficiency

A well-organized sample room accelerates prototype approval, reducing design iteration time by up to 30%, which directly shortens overall turnaround time. Production floors optimized for workflow minimize labor costs and material waste, improving cost efficiency by an average of 25%. Balancing resources between sample room precision and production floor volume is crucial to achieving faster delivery with lower expenses.

Sample Room vs Production Floor Infographic

bizdif.com

bizdif.com