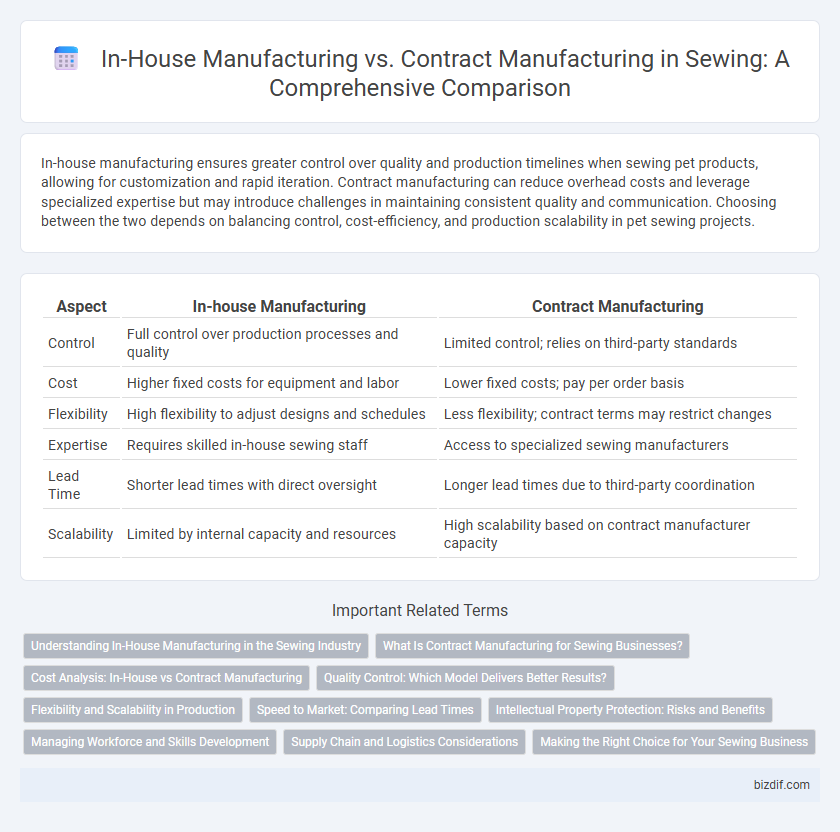

In-house manufacturing ensures greater control over quality and production timelines when sewing pet products, allowing for customization and rapid iteration. Contract manufacturing can reduce overhead costs and leverage specialized expertise but may introduce challenges in maintaining consistent quality and communication. Choosing between the two depends on balancing control, cost-efficiency, and production scalability in pet sewing projects.

Table of Comparison

| Aspect | In-house Manufacturing | Contract Manufacturing |

|---|---|---|

| Control | Full control over production processes and quality | Limited control; relies on third-party standards |

| Cost | Higher fixed costs for equipment and labor | Lower fixed costs; pay per order basis |

| Flexibility | High flexibility to adjust designs and schedules | Less flexibility; contract terms may restrict changes |

| Expertise | Requires skilled in-house sewing staff | Access to specialized sewing manufacturers |

| Lead Time | Shorter lead times with direct oversight | Longer lead times due to third-party coordination |

| Scalability | Limited by internal capacity and resources | High scalability based on contract manufacturer capacity |

Understanding In-House Manufacturing in the Sewing Industry

In-house manufacturing in the sewing industry involves producing garments or textiles within a company's own facilities, allowing for greater control over quality, production timelines, and customization. This approach enables sewing businesses to implement proprietary techniques, maintain strict quality standards, and quickly adapt to design changes without relying on external suppliers. Investing in in-house manufacturing often leads to improved efficiency, reduced lead times, and enhanced capacity for innovation in garment production.

What Is Contract Manufacturing for Sewing Businesses?

Contract manufacturing for sewing businesses involves outsourcing production to specialized factories that handle garment assembly and finishing processes. This model allows companies to leverage external expertise, reduce overhead costs, and scale production without investing in in-house facilities or labor. Key advantages include access to advanced sewing technologies, flexible order fulfillment, and faster market entry.

Cost Analysis: In-House vs Contract Manufacturing

In-house manufacturing often requires significant upfront investment in equipment, labor, and facilities, leading to higher fixed costs but greater control over production quality and timelines. Contract manufacturing typically offers lower initial expenses and variable costs based on order volume, but may involve additional expenses such as shipping, quality inspections, and potential communication delays. A comprehensive cost analysis should weigh both direct manufacturing costs and indirect factors like inventory management, scalability, and risk of production disruptions to determine the most cost-effective approach.

Quality Control: Which Model Delivers Better Results?

In-house manufacturing offers greater control over quality assurance processes, enabling real-time inspections and immediate corrective actions in sewing production. Contract manufacturing can introduce variability due to differing standards and less oversight, potentially impacting garment consistency and durability. Companies prioritizing premium quality often favor in-house setups to maintain stringent sewing quality controls and ensure superior final products.

Flexibility and Scalability in Production

In-house manufacturing offers greater flexibility, allowing seamless adjustments to design changes and production schedules tailored to immediate business needs. Contract manufacturing provides superior scalability by leveraging specialized facilities and resources to handle large volume orders efficiently. Balancing these advantages helps sewing businesses optimize production capacity while maintaining adaptability to market fluctuations.

Speed to Market: Comparing Lead Times

In-house manufacturing offers faster lead times by streamlining communication and eliminating intermediaries, which accelerates the sewing process from design to production. Contract manufacturing often involves longer lead times due to logistics coordination, higher order minimums, and potential scheduling conflicts with other clients. Brands seeking rapid speed to market typically favor in-house production for its agility and immediate response capabilities.

Intellectual Property Protection: Risks and Benefits

In-house manufacturing offers greater control over intellectual property (IP) protection by limiting access to proprietary designs and processes within the company, reducing the risk of IP theft or leakage. Contract manufacturing can expose businesses to higher IP risks due to reliance on external partners, who may not have stringent security measures or may service multiple clients with potentially conflicting interests. Implementing robust non-disclosure agreements (NDAs) and selecting reputable contract manufacturers with proven IP protection policies can mitigate these risks while benefiting from cost efficiencies and specialized expertise.

Managing Workforce and Skills Development

In-house manufacturing enables direct control over workforce management and tailored skills development, fostering specialized expertise aligned with company standards. Contract manufacturing offers flexibility by leveraging external skilled labor but may limit direct oversight of employee training and quality consistency. Efficient workforce management in in-house setups often results in higher adaptability to production changes and innovation in sewing techniques.

Supply Chain and Logistics Considerations

In-house manufacturing offers greater control over supply chain processes and inventory management, resulting in faster response times and reduced lead times for sewing production. Contract manufacturing relies on third-party suppliers, which can introduce risks such as shipping delays, customs clearance issues, and less visibility into real-time inventory tracking. Optimizing logistics through strategic partnerships and integrated supply chain software is critical for minimizing disruptions and ensuring consistent delivery schedules in both manufacturing models.

Making the Right Choice for Your Sewing Business

In-house manufacturing offers complete control over quality and production timelines, essential for sewing businesses prioritizing customization and consistent craftsmanship. Contract manufacturing provides scalability and cost-efficiency by leveraging specialized expertise and advanced equipment without significant capital investment. Evaluating factors such as order volume, quality standards, budget, and turnaround time helps determine the ideal manufacturing model for optimizing sewing business operations and profitability.

In-house Manufacturing vs Contract Manufacturing Infographic

bizdif.com

bizdif.com