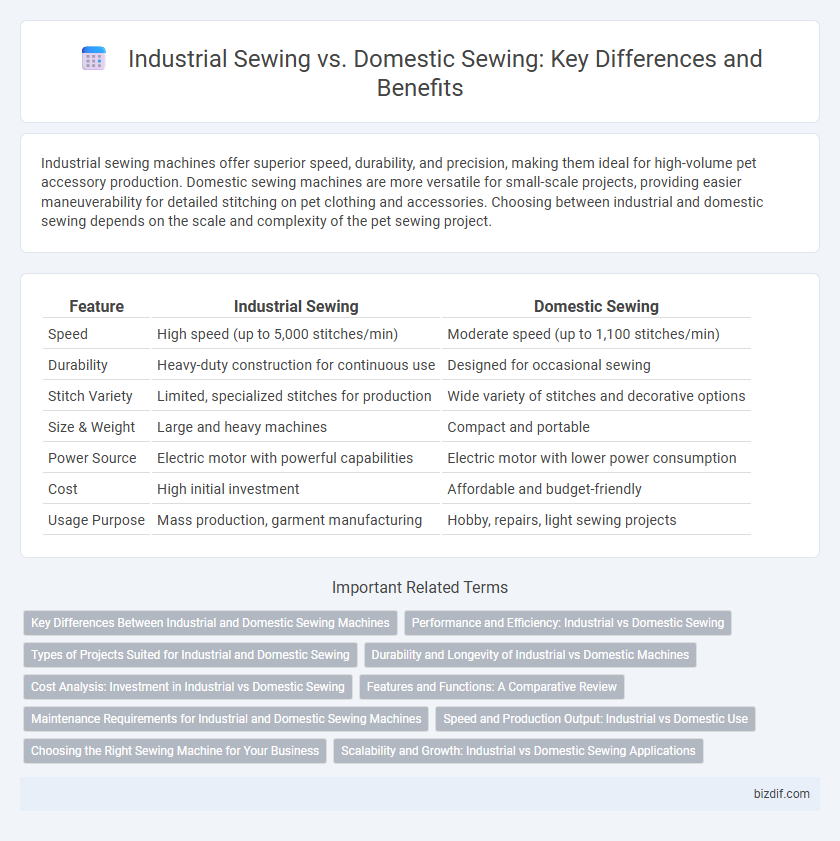

Industrial sewing machines offer superior speed, durability, and precision, making them ideal for high-volume pet accessory production. Domestic sewing machines are more versatile for small-scale projects, providing easier maneuverability for detailed stitching on pet clothing and accessories. Choosing between industrial and domestic sewing depends on the scale and complexity of the pet sewing project.

Table of Comparison

| Feature | Industrial Sewing | Domestic Sewing |

|---|---|---|

| Speed | High speed (up to 5,000 stitches/min) | Moderate speed (up to 1,100 stitches/min) |

| Durability | Heavy-duty construction for continuous use | Designed for occasional sewing |

| Stitch Variety | Limited, specialized stitches for production | Wide variety of stitches and decorative options |

| Size & Weight | Large and heavy machines | Compact and portable |

| Power Source | Electric motor with powerful capabilities | Electric motor with lower power consumption |

| Cost | High initial investment | Affordable and budget-friendly |

| Usage Purpose | Mass production, garment manufacturing | Hobby, repairs, light sewing projects |

Key Differences Between Industrial and Domestic Sewing Machines

Industrial sewing machines are designed for high-speed, heavy-duty tasks, featuring robust motors, specialized functions, and durable components ideal for continuous use in manufacturing environments. Domestic sewing machines offer versatility with multiple stitch options, user-friendly interfaces, and portability suited for household projects and occasional sewing. Key differences include stitch speed, motor power, durability, and specialization, where industrial machines prioritize efficiency and consistency, while domestic machines emphasize versatility and ease of use.

Performance and Efficiency: Industrial vs Domestic Sewing

Industrial sewing machines deliver significantly higher performance and efficiency, producing thousands of stitches per minute with powerful motors designed for continuous use in manufacturing environments. Their robust construction allows for consistent, precise stitching on heavy fabrics, reducing downtime and increasing production speed compared to domestic machines. Domestic sewing machines are ideal for smaller projects with lower output demands, offering versatility but lacking the speed and durability required for large-scale industrial applications.

Types of Projects Suited for Industrial and Domestic Sewing

Industrial sewing machines excel in high-volume production, handling heavy fabrics and complex stitching required for garments, upholstery, and leather goods efficiently. Domestic sewing machines are ideal for small-scale projects such as home decor, quilting, alterations, and lightweight fabric garments. Project scale, fabric type, and stitching complexity determine the suitability of industrial versus domestic sewing equipment.

Durability and Longevity of Industrial vs Domestic Machines

Industrial sewing machines feature robust metal components and high-powered motors designed for continuous, heavy-duty use, resulting in exceptional durability and long service life. Domestic sewing machines, typically constructed with more plastic parts and lower-powered motors, cater to lighter sewing tasks and may require more frequent maintenance or replacement. The superior build quality and speed of industrial machines ensure they withstand intensive workloads, making them ideal for professional environments demanding longevity and reliability.

Cost Analysis: Investment in Industrial vs Domestic Sewing

Industrial sewing machines require a significantly higher initial investment, often ranging from $1,000 to $10,000, compared to domestic machines priced between $100 and $1,000. The cost analysis includes maintenance expenses, with industrial machines demanding professional servicing and more expensive parts, while domestic machines have lower upkeep costs and widely available replacement components. Long-term productivity gains and durability of industrial machines can offset the upfront costs, making them more cost-effective for mass production, whereas domestic machines are better suited for occasional, small-scale projects with minimal financial commitment.

Features and Functions: A Comparative Review

Industrial sewing machines offer higher speed, durability, and the capability to handle heavy fabrics, making them essential for mass production and complex stitching tasks. Domestic sewing machines prioritize user-friendly features such as multiple stitch options, portability, and ease of use, catering to hobbyists and small-scale projects. The advanced motor power, specialized attachments, and continuous operation capacity distinguish industrial machines from domestic ones in terms of functionality and efficiency.

Maintenance Requirements for Industrial and Domestic Sewing Machines

Industrial sewing machines require frequent and specialized maintenance due to their high-speed operation and continuous use in production environments, often necessitating professional servicing and replacement of heavy-duty components. Domestic sewing machines demand less intensive maintenance, typically involving regular cleaning, oiling, and occasional part replacement managed by the user to ensure smooth functioning during intermittent use. Proper maintenance schedules tailored to the machine type significantly extend the lifespan and performance efficiency of both industrial and domestic sewing machines.

Speed and Production Output: Industrial vs Domestic Use

Industrial sewing machines offer significantly higher speed and production output compared to domestic models, with some machines capable of over 5,000 stitches per minute. These machines are engineered for continuous, heavy-duty use in manufacturing environments, ensuring consistent performance and durability. In contrast, domestic sewing machines typically operate at slower speeds, around 600 to 1,200 stitches per minute, making them more suitable for occasional, smaller-scale projects rather than mass production.

Choosing the Right Sewing Machine for Your Business

Selecting the ideal sewing machine for your business depends on the scope and volume of your production; industrial sewing machines offer high speed, durability, and specialized functions suitable for large-scale manufacturing, while domestic sewing machines are best for small-scale or custom projects due to their versatility and portability. Industrial machines handle heavy fabrics and continuous use efficiently, reducing downtime and increasing output, which is essential for meeting commercial demands. Evaluating factors such as stitch types, motor power, maintenance requirements, and budget will guide you in choosing a machine that optimizes productivity and quality in your sewing operations.

Scalability and Growth: Industrial vs Domestic Sewing Applications

Industrial sewing machines offer significantly higher scalability and growth potential due to their robust construction, enhanced speed, and ability to handle heavy-duty fabrics continuously, making them ideal for mass production environments. Domestic sewing machines, while more affordable and versatile for small-scale projects, are limited by lower operational speed, reduced durability, and smaller workloads, restricting their growth to hobbyist or small business levels. Manufacturers seeking to expand production capacity and output efficiency typically prefer industrial sewing applications to meet large order volumes and maintain consistent quality.

Industrial sewing vs Domestic sewing Infographic

bizdif.com

bizdif.com