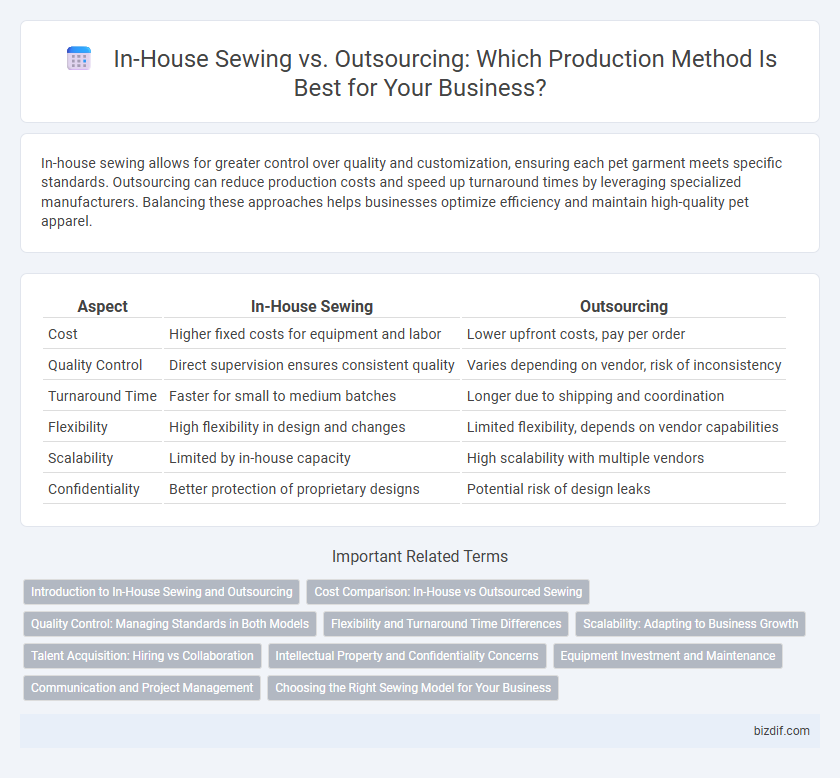

In-house sewing allows for greater control over quality and customization, ensuring each pet garment meets specific standards. Outsourcing can reduce production costs and speed up turnaround times by leveraging specialized manufacturers. Balancing these approaches helps businesses optimize efficiency and maintain high-quality pet apparel.

Table of Comparison

| Aspect | In-House Sewing | Outsourcing |

|---|---|---|

| Cost | Higher fixed costs for equipment and labor | Lower upfront costs, pay per order |

| Quality Control | Direct supervision ensures consistent quality | Varies depending on vendor, risk of inconsistency |

| Turnaround Time | Faster for small to medium batches | Longer due to shipping and coordination |

| Flexibility | High flexibility in design and changes | Limited flexibility, depends on vendor capabilities |

| Scalability | Limited by in-house capacity | High scalability with multiple vendors |

| Confidentiality | Better protection of proprietary designs | Potential risk of design leaks |

Introduction to In-House Sewing and Outsourcing

In-house sewing offers direct control over production quality, timelines, and customization, making it ideal for brands emphasizing craftsmanship and rapid prototyping. Outsourcing leverages specialized factories and lower labor costs, optimizing scalability and reducing overhead expenses for large-volume orders. Choosing between these approaches depends on factors like budget constraints, production capacity, and the desired level of process oversight in the garment manufacturing workflow.

Cost Comparison: In-House vs Outsourced Sewing

In-house sewing typically incurs higher fixed costs due to equipment investment, labor wages, and facility maintenance, while outsourced sewing often reduces these expenses through economies of scale and specialized labor. Variable costs in outsourcing can fluctuate based on order volume and complexity, offering flexibility but potential price variability compared to the consistent overhead of in-house production. Companies must analyze total cost of ownership, including quality control and lead times, to determine the most cost-effective sewing solution.

Quality Control: Managing Standards in Both Models

In-house sewing allows direct oversight of quality control processes, ensuring consistent adherence to garment specifications and immediate rectification of defects. Outsourcing requires robust communication and stringent supplier audits to maintain quality standards, often relying on third-party inspections to manage compliance. Both models demand precise quality management systems to uphold product integrity and customer satisfaction.

Flexibility and Turnaround Time Differences

In-house sewing offers greater flexibility by allowing immediate adjustments to production schedules and design changes, enhancing responsiveness to market demands. Outsourcing typically involves longer turnaround times due to communication lags and shipping, which can delay product delivery. Efficient in-house sewing operations reduce lead times and enable faster response to customer needs compared to the fixed timelines in outsourcing contracts.

Scalability: Adapting to Business Growth

In-house sewing offers greater control over quality and production timelines but may face limitations in scaling quickly due to fixed workforce and equipment capacity. Outsourcing provides flexibility to adapt rapidly to increased demand by leveraging external manufacturers with larger production capabilities. Businesses focusing on scalability often use a hybrid approach, maintaining core competencies internally while outsourcing overflow to meet growth efficiently.

Talent Acquisition: Hiring vs Collaboration

In-house sewing offers greater control over talent acquisition, allowing direct hiring and training of skilled seamstresses aligned with company standards. Outsourcing leverages collaboration with specialized workshops that bring diverse expertise without the overhead of recruitment and employee management. Choosing between these approaches depends on balancing the need for customized craftsmanship and operational flexibility in production workflows.

Intellectual Property and Confidentiality Concerns

In-house sewing ensures greater control over intellectual property by keeping proprietary designs and techniques within the company, reducing the risk of unauthorized replication. Confidentiality is enhanced as access to sensitive materials is limited to trusted internal staff, minimizing potential leaks. Outsourcing sewing to third parties increases vulnerability to intellectual property theft and confidentiality breaches, especially if strict non-disclosure agreements and monitoring protocols are not rigorously enforced.

Equipment Investment and Maintenance

In-house sewing requires significant investment in high-quality sewing machines, cutting equipment, and regular maintenance to ensure optimal performance and reduce downtime. Outsourcing eliminates the need for upfront capital expenditure and ongoing equipment upkeep, transferring these responsibilities to specialized manufacturers. Choosing in-house sewing allows greater control over production quality and timelines, while outsourcing focuses on cost savings by avoiding equipment-related expenses.

Communication and Project Management

In-house sewing allows for direct communication between design and production teams, enabling immediate feedback and quicker adjustments during garment creation. Project management benefits from closer oversight, streamlined workflow, and real-time monitoring of progress, which reduces delays and enhances quality control. Outsourcing sewing can introduce communication challenges and project management complexities, requiring robust coordination tools and clear documentation to maintain alignment and meet deadlines efficiently.

Choosing the Right Sewing Model for Your Business

Selecting the right sewing model for your business depends on factors such as production volume, cost efficiency, and quality control. In-house sewing offers greater oversight and faster iterative processes, while outsourcing provides scalability and access to specialized skills. Evaluating your business priorities, budget constraints, and turnaround times ensures the optimal balance between flexibility and operational efficiency.

In-house sewing vs outsourcing Infographic

bizdif.com

bizdif.com