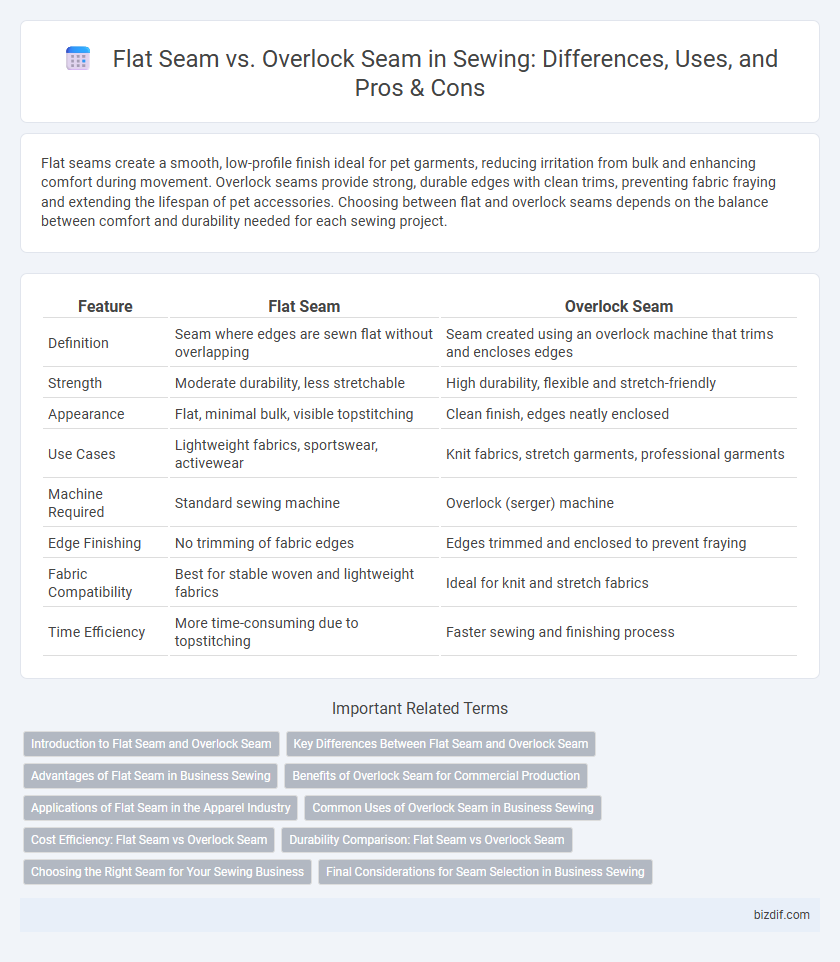

Flat seams create a smooth, low-profile finish ideal for pet garments, reducing irritation from bulk and enhancing comfort during movement. Overlock seams provide strong, durable edges with clean trims, preventing fabric fraying and extending the lifespan of pet accessories. Choosing between flat and overlock seams depends on the balance between comfort and durability needed for each sewing project.

Table of Comparison

| Feature | Flat Seam | Overlock Seam |

|---|---|---|

| Definition | Seam where edges are sewn flat without overlapping | Seam created using an overlock machine that trims and encloses edges |

| Strength | Moderate durability, less stretchable | High durability, flexible and stretch-friendly |

| Appearance | Flat, minimal bulk, visible topstitching | Clean finish, edges neatly enclosed |

| Use Cases | Lightweight fabrics, sportswear, activewear | Knit fabrics, stretch garments, professional garments |

| Machine Required | Standard sewing machine | Overlock (serger) machine |

| Edge Finishing | No trimming of fabric edges | Edges trimmed and enclosed to prevent fraying |

| Fabric Compatibility | Best for stable woven and lightweight fabrics | Ideal for knit and stretch fabrics |

| Time Efficiency | More time-consuming due to topstitching | Faster sewing and finishing process |

Introduction to Flat Seam and Overlock Seam

Flat seams create a smooth, low-profile finish by stitching fabric edges together and pressing them open, reducing bulk for comfortable wear and durability. Overlock seams use multiple threads to simultaneously stitch, trim, and finish fabric edges, providing a secure and stretchy seam ideal for knit and stretch fabrics. Both seam types enhance garment quality, with flat seams favored for comfort and overlock seams for efficient edge finishing.

Key Differences Between Flat Seam and Overlock Seam

Flat seams lie completely flat on the fabric surface, offering minimal bulk and enhanced comfort, making them ideal for activewear and sports garments. Overlock seams use multiple threads to trim, sew, and finish the fabric edge simultaneously, providing a durable, stretchy, and professional finish commonly seen in knit fabrics. The key differences include flat seams' low profile and reduced irritation versus overlock seams' superior edge reinforcement and stretchability.

Advantages of Flat Seam in Business Sewing

Flat seams enhance business sewing efficiency by reducing bulk, resulting in smoother, more comfortable garments that appeal to consumers seeking quality and comfort. Their durability and lower material waste contribute to cost-effective production, making them ideal for high-volume manufacturing environments. The seamless finish also improves the aesthetic value of products, increasing customer satisfaction and brand reputation.

Benefits of Overlock Seam for Commercial Production

Overlock seams provide enhanced durability and professional finish ideal for commercial production environments, significantly reducing fraying and increasing garment lifespan. The high-speed stitching of overlock machines improves efficiency, allowing manufacturers to produce large volumes with consistent quality. Seam flexibility and stretchability make overlock sewings particularly suitable for knit and stretch fabrics commonly used in mass-market clothing.

Applications of Flat Seam in the Apparel Industry

Flat seams are widely used in activewear and sportswear due to their ability to reduce bulk and minimize chafing, providing enhanced comfort and flexibility. This seam type is ideal for garments requiring a sleek finish and durability, such as cycling jerseys, swimwear, and leggings. Flat seams also improve garment aesthetics by allowing smooth, continuous fabric surfaces, making them popular in both performance and fashion apparel.

Common Uses of Overlock Seam in Business Sewing

Overlock seams are commonly used in business sewing for finishing edges and preventing fabric fraying, ensuring garment durability and professional quality. These seams are especially favored in activewear, lingerie, and knitwear production due to their stretchability and neat appearance. High-speed overlock machines enable efficient mass production, which is essential for meeting commercial demand and maintaining consistent seam strength.

Cost Efficiency: Flat Seam vs Overlock Seam

Flat seams offer superior cost efficiency for sewing projects due to minimal thread usage and reduced machine maintenance compared to overlock seams. Overlock seams, while providing strong and stretchy edges ideal for knit fabrics, require specialized machines and multiple threads, increasing overall production costs. Choosing flat seams can significantly lower material expenses and simplify workflow in high-volume, budget-conscious garment manufacturing.

Durability Comparison: Flat Seam vs Overlock Seam

Flat seams offer superior durability due to their double-stitched construction, which evenly distributes stress and resists fraying, making them ideal for heavy-duty fabrics. Overlock seams, while quicker to produce, typically use multiple threads to encase fabric edges, providing moderate durability but potentially less strength under high tension. For garments requiring long-lasting wear and reinforced strength, flat seams outperform overlock seams in maintaining structural integrity over time.

Choosing the Right Seam for Your Sewing Business

Flat seams offer a smooth, low-bulk finish ideal for activewear and knit fabrics, enhancing comfort and flexibility. Overlock seams provide durable, clean edges perfect for preventing fraying on woven materials, boosting garment longevity. Selecting the right seam depends on fabric type, garment function, and production efficiency, crucial factors for a successful sewing business.

Final Considerations for Seam Selection in Business Sewing

Choosing between flat seams and overlock seams in business sewing hinges on factors such as fabric type, garment durability, and production speed. Flat seams offer minimal bulk and enhanced comfort, making them ideal for athletic and knitwear, while overlock seams provide strong edge finishing and prevent fraying, suited for woven fabrics and mass production. Cost efficiency and machine capabilities also influence seam selection, affecting overall garment quality and manufacturing timelines.

Flat Seam vs Overlock Seam Infographic

bizdif.com

bizdif.com