Upholstery sewing requires thicker, more durable threads and specialized needles to handle heavy fabrics like leather and canvas, while garment sewing typically uses lighter threads suited for softer materials such as cotton or silk. The techniques differ as upholstery involves reinforced stitching for strength and longevity, whereas garment sewing prioritizes flexibility and comfort. Mastery of both styles enhances versatility in sewing projects, allowing for precise repairs and custom creations across different fabric types.

Table of Comparison

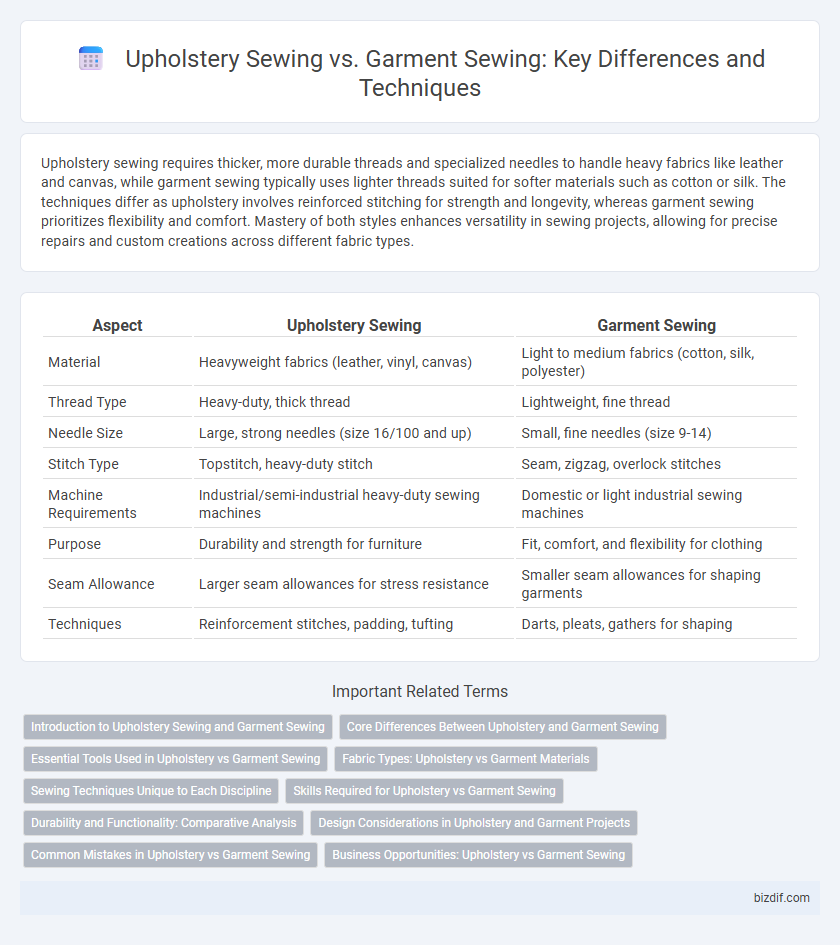

| Aspect | Upholstery Sewing | Garment Sewing |

|---|---|---|

| Material | Heavyweight fabrics (leather, vinyl, canvas) | Light to medium fabrics (cotton, silk, polyester) |

| Thread Type | Heavy-duty, thick thread | Lightweight, fine thread |

| Needle Size | Large, strong needles (size 16/100 and up) | Small, fine needles (size 9-14) |

| Stitch Type | Topstitch, heavy-duty stitch | Seam, zigzag, overlock stitches |

| Machine Requirements | Industrial/semi-industrial heavy-duty sewing machines | Domestic or light industrial sewing machines |

| Purpose | Durability and strength for furniture | Fit, comfort, and flexibility for clothing |

| Seam Allowance | Larger seam allowances for stress resistance | Smaller seam allowances for shaping garments |

| Techniques | Reinforcement stitches, padding, tufting | Darts, pleats, gathers for shaping |

Introduction to Upholstery Sewing and Garment Sewing

Upholstery sewing involves working with heavy-duty fabrics like leather and canvas, requiring specialized needles and strong thread to withstand wear and tear on furniture. Garment sewing focuses on lighter, flexible fabrics such as cotton or silk, emphasizing precision and comfort in clothing construction. Techniques in upholstery sewing prioritize durability and structural reinforcement, while garment sewing balances aesthetics with fit and movement.

Core Differences Between Upholstery and Garment Sewing

Upholstery sewing involves working with heavy-duty fabrics like leather, canvas, or vinyl, requiring industrial-strength needles and strong upholstery threads to withstand wear and tear. Garment sewing typically uses lighter fabrics such as cotton, silk, or polyester, necessitating finer needles and specialized stitches for flexibility and comfort. The construction techniques in upholstery emphasize durability and structural integrity, while garment sewing prioritizes fit, drape, and aesthetic details.

Essential Tools Used in Upholstery vs Garment Sewing

Upholstery sewing requires heavy-duty tools such as industrial-grade sewing machines, heavy-duty needles, and specialized upholstery threads designed to withstand tension and wear. In contrast, garment sewing utilizes lighter machines, fine needles, and softer threads tailored for delicate fabrics like cotton and silk. Essential upholstery tools also include staple guns, webbing stretchers, and tack lifters, absent in garment sewing setups where precision scissors and seam rippers are more common.

Fabric Types: Upholstery vs Garment Materials

Upholstery sewing utilizes heavy-duty fabrics such as leather, canvas, and vinyl designed for durability and abrasion resistance, contrasting with garment sewing's emphasis on lighter, breathable materials like cotton, silk, and polyester blends. The thick, sturdy textures in upholstery fabrics require specialized needles and heavy-duty sewing machines to handle dense layers and resist wear over time. Conversely, garment fabrics prioritize softness and flexibility to provide comfort and ease of movement, influencing stitch types and thread choices.

Sewing Techniques Unique to Each Discipline

Upholstery sewing involves heavy-duty stitching techniques such as topstitching and reinforced seams to handle thick fabrics and multiple layers, ensuring durability and structure in furniture coverings. Garment sewing emphasizes precision with techniques like darting, gathering, and fine seam finishes, tailored for flexibility and comfort in clothing fit. Each discipline requires specialized needles, threads, and stitch types optimized for the material weight and end-use functionality.

Skills Required for Upholstery vs Garment Sewing

Upholstery sewing demands advanced skills in handling heavy-duty fabrics such as leather, vinyl, and canvas, requiring specialized equipment like industrial sewing machines and heavy-duty needles that differ significantly from garment sewing tools. Precision in stitching to ensure durability and maintaining fabric tension over thick layers is crucial, contrasting with garment sewing's emphasis on creating flexible, comfortable seams using lighter fabrics like cotton and silk. Mastery of techniques such as welt seams, piping, and pattern alignment for upholstery projects reflects a more technical skill set compared to the fitting and tailoring skills emphasized in garment construction.

Durability and Functionality: Comparative Analysis

Upholstery sewing prioritizes durability and heavy-duty functionality, utilizing thicker threads, robust stitches, and reinforced seams designed to withstand frequent use and tension on furniture surfaces. Garment sewing focuses more on flexibility, comfort, and aesthetics, employing lighter fabrics, finer threads, and delicate stitching techniques suitable for wearability and movement. The contrasting requirements highlight upholstery sewing's emphasis on strength and longevity, while garment sewing balances durability with wearability and style.

Design Considerations in Upholstery and Garment Projects

Upholstery sewing requires prioritizing durability and fabric thickness to withstand heavy use, whereas garment sewing emphasizes comfort and flexibility with lighter, breathable materials. Design considerations in upholstery often include reinforcing seams with strong stitching techniques and incorporating padding or interfacing for structural support. In garment projects, design decisions focus on fit and drape, utilizing stretch seams and finer threads to ensure aesthetic appeal and ease of movement.

Common Mistakes in Upholstery vs Garment Sewing

Common mistakes in upholstery sewing often include improper seam allowances, inadequate reinforcement for heavy fabrics, and neglecting to use the correct needle size for thick materials. In garment sewing, errors frequently involve misaligned patterns, incorrect fabric grain cutting, and insufficient finishing techniques for seams. Both types of sewing require attention to fabric type and stitch strength, but upholstery demands stronger thread tension and specialized tools due to its durability requirements.

Business Opportunities: Upholstery vs Garment Sewing

Upholstery sewing offers lucrative business opportunities due to high demand in furniture restoration, custom decor, and commercial interiors, often commanding higher prices per project than garment sewing. The upholstery market benefits from larger, durable materials and less seasonal fluctuation compared to garment sewing, which faces intense competition and rapid fashion cycles. Specialized skills in upholstery can lead to niche markets with long-term client relationships, whereas garment sewing demands fast production and trend adaptation to maintain profitability.

Upholstery sewing vs garment sewing Infographic

bizdif.com

bizdif.com