Manual stitching in sewing pets offers precise control and customization, allowing for detailed handiwork that caters to unique designs and delicate fabrics. Automated stitching increases efficiency and consistency, producing uniform seams quickly while reducing labor costs and minimizing human error. Choosing between manual and automated stitching depends on the desired balance between craftsmanship quality and production speed.

Table of Comparison

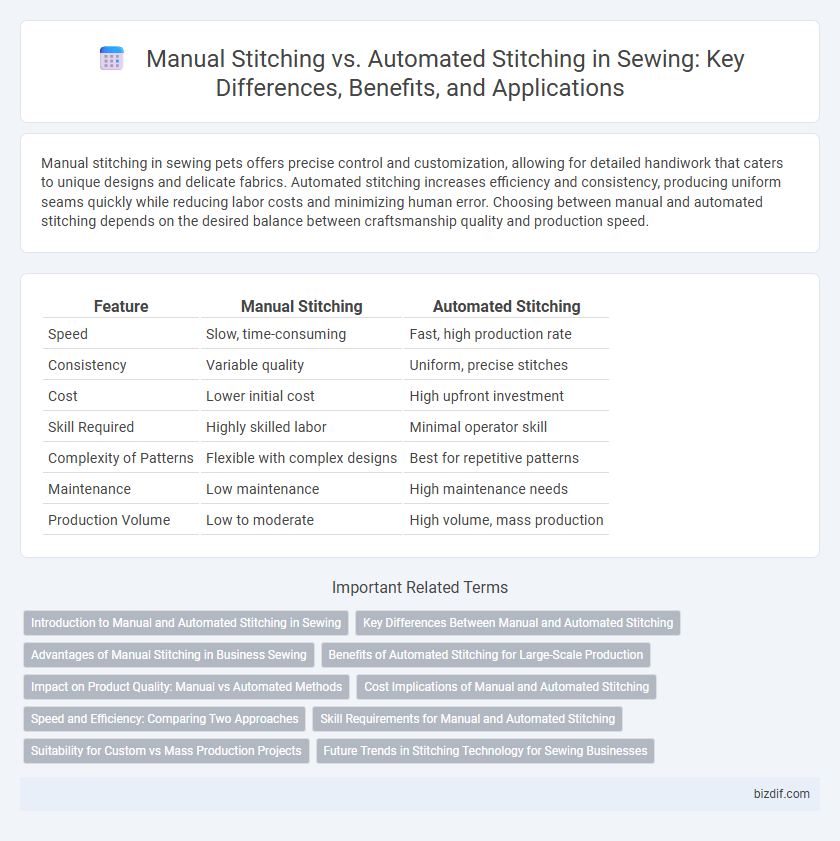

| Feature | Manual Stitching | Automated Stitching |

|---|---|---|

| Speed | Slow, time-consuming | Fast, high production rate |

| Consistency | Variable quality | Uniform, precise stitches |

| Cost | Lower initial cost | High upfront investment |

| Skill Required | Highly skilled labor | Minimal operator skill |

| Complexity of Patterns | Flexible with complex designs | Best for repetitive patterns |

| Maintenance | Low maintenance | High maintenance needs |

| Production Volume | Low to moderate | High volume, mass production |

Introduction to Manual and Automated Stitching in Sewing

Manual stitching involves hand-sewing techniques where artisans use needles and thread to create precise, customizable seams, ideal for intricate or delicate fabric work. Automated stitching employs computerized sewing machines that deliver consistent, high-speed stitching, enhancing productivity and uniformity in mass production settings. Both methods play vital roles in the textile industry, balancing craftsmanship and efficiency depending on project requirements.

Key Differences Between Manual and Automated Stitching

Manual stitching involves hand-sewing techniques that offer precision and customization, ideal for intricate or delicate fabric work. Automated stitching uses sewing machines with programmed patterns, enabling faster production and consistent stitch quality on large-scale manufacturing. Key differences include speed, accuracy, labor intensity, and suitability for either artisanal craftsmanship or mass production.

Advantages of Manual Stitching in Business Sewing

Manual stitching in business sewing offers unparalleled precision and customization, allowing artisans to tailor each garment to unique specifications and intricate designs that automated machines may struggle to replicate. The tactile feedback and control enable higher quality finishes, especially in luxury and bespoke items where attention to detail drives customer satisfaction. This craftsmanship enhances brand value and supports niche markets that prioritize handmade quality over mass production.

Benefits of Automated Stitching for Large-Scale Production

Automated stitching significantly enhances efficiency in large-scale production by delivering consistent stitch quality at high speeds, reducing human error and labor costs. Industrial sewing machines equipped with computerized controls enable precise and complex stitch patterns, increasing product uniformity and minimizing material waste. This automation ultimately boosts overall productivity and streamlines manufacturing processes in textile and garment industries.

Impact on Product Quality: Manual vs Automated Methods

Manual stitching offers greater precision and control, allowing artisans to produce intricate details and customized finishes that enhance product quality. Automated stitching ensures consistent stitch length and tension, reducing human error and increasing uniformity across large production runs. Combining manual techniques with automated methods can optimize both craftsmanship and efficiency, elevating overall garment quality.

Cost Implications of Manual and Automated Stitching

Manual stitching typically incurs higher labor costs due to the time-intensive nature of hand-sewing, making it less cost-effective for large-scale production. Automated stitching significantly reduces labor expenses and increases production speed, resulting in lower overall manufacturing costs. The initial investment in automated machinery can be high, but the long-term savings in labor and higher output often offset these upfront expenses.

Speed and Efficiency: Comparing Two Approaches

Manual stitching offers precision and control, making it ideal for intricate designs, but it is significantly slower compared to automated stitching. Automated stitching machines enhance production speed and efficiency by consistently delivering uniform stitches at high volumes, reducing labor costs. The contrast in stitching velocity impacts workflow optimization, with automation favored in large-scale manufacturing environments.

Skill Requirements for Manual and Automated Stitching

Manual stitching demands high levels of skill, precision, and hand-eye coordination, as it relies on the artisan's expertise to control stitch length, tension, and consistency. Automated stitching significantly reduces the need for specialized hand skills, relying instead on machine programming and maintenance knowledge to ensure accurate and uniform stitches. Skilled operators are essential for setting up, monitoring, and troubleshooting automated sewing machines to maintain production quality and efficiency.

Suitability for Custom vs Mass Production Projects

Manual stitching offers unparalleled precision and customization, making it ideal for bespoke garments and intricate designs where individual craftsmanship is paramount. Automated stitching excels in mass production settings, delivering consistent quality and rapid output suitable for standardized apparel manufacturing. Choosing between manual and automated stitching depends on project scale and the need for personalized detail versus high-volume efficiency.

Future Trends in Stitching Technology for Sewing Businesses

Future trends in stitching technology for sewing businesses emphasize the integration of advanced robotics and AI-driven precision to enhance efficiency and consistency. Manual stitching remains valued for bespoke, intricate designs, but automated stitching machines equipped with smart sensors and real-time monitoring systems significantly reduce material waste and production time. Emerging innovations such as programmable stitching patterns and IoT-connected machinery promise to revolutionize customization and scalability in the apparel manufacturing industry.

Manual Stitching vs Automated Stitching Infographic

bizdif.com

bizdif.com