Manual sewing allows for precise, customizable stitching ideal for unique pet accessories, while automated sewing offers consistent speed and uniformity for bulk production. Handmade techniques accommodate intricate designs and delicate fabrics, ensuring a tailored fit for pets. Automated machines enhance efficiency, reducing labor time and minimizing errors in large-scale sewing projects.

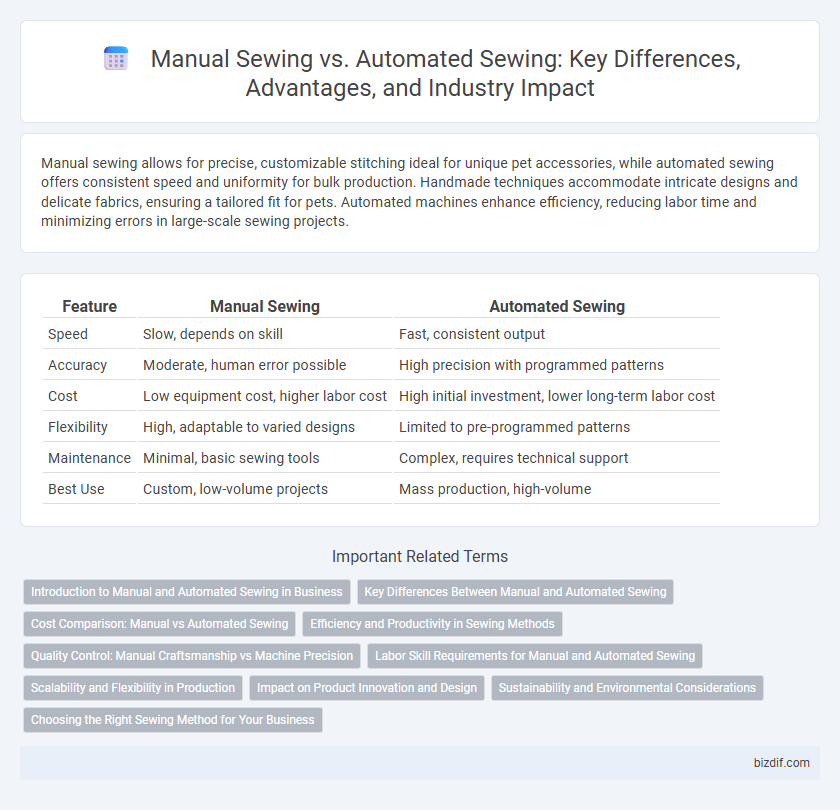

Table of Comparison

| Feature | Manual Sewing | Automated Sewing |

|---|---|---|

| Speed | Slow, depends on skill | Fast, consistent output |

| Accuracy | Moderate, human error possible | High precision with programmed patterns |

| Cost | Low equipment cost, higher labor cost | High initial investment, lower long-term labor cost |

| Flexibility | High, adaptable to varied designs | Limited to pre-programmed patterns |

| Maintenance | Minimal, basic sewing tools | Complex, requires technical support |

| Best Use | Custom, low-volume projects | Mass production, high-volume |

Introduction to Manual and Automated Sewing in Business

Manual sewing involves skilled artisans using hand tools and basic machines to create detailed, customizable garments, offering flexibility for small-scale or bespoke business operations. Automated sewing employs advanced machinery and robotics to accelerate production, ensure consistent quality, and reduce labor costs in large-scale manufacturing environments. Businesses selecting between manual and automated sewing must consider factors such as production volume, customization needs, and cost-efficiency to align with their operational goals.

Key Differences Between Manual and Automated Sewing

Manual sewing involves hand-stitching techniques that offer precision and control for intricate designs and small-scale projects. Automated sewing utilizes computerized machines to increase production speed, consistency, and efficiency in mass manufacturing environments. Key differences include the level of human involvement, stitch uniformity, and scalability, with automated sewing excelling in high-volume output and manual sewing favored for customization and detailed craftsmanship.

Cost Comparison: Manual vs Automated Sewing

Manual sewing incurs lower initial expenses due to minimal equipment requirements, making it cost-effective for small-scale projects. Automated sewing involves significant upfront investment in machinery and maintenance but offers reduced labor costs and higher productivity over time. Businesses must weigh the balance between one-time capital outlay and long-term operational savings when selecting sewing methods.

Efficiency and Productivity in Sewing Methods

Manual sewing offers precise control over intricate details, ideal for custom or small-scale projects, but it is time-consuming and less suited for high-volume production. Automated sewing significantly boosts efficiency and productivity by rapidly executing repetitive tasks with consistent quality, making it essential for large-scale garment manufacturing. Advanced sewing machines equipped with computerized controls streamline workflows, reduce labor costs, and enhance output speed compared to traditional hand sewing methods.

Quality Control: Manual Craftsmanship vs Machine Precision

Manual sewing offers unparalleled craftsmanship, allowing skilled artisans to inspect each stitch for consistency and adjust techniques in real-time, enhancing garment uniqueness and detail. Automated sewing machines provide high precision and uniformity, significantly reducing human error and ensuring consistent stitch quality across large production runs. Combining manual inspection with machine precision optimizes quality control by balancing creativity with efficiency in textile manufacturing.

Labor Skill Requirements for Manual and Automated Sewing

Manual sewing necessitates highly skilled labor with expertise in hand-stitching techniques, precision, and fabric handling to ensure quality and intricate detailing. Automated sewing reduces the reliance on skilled labor by utilizing programmed machines capable of consistent stitching, but it requires operators knowledgeable in machine maintenance and programming. The shift from manual to automated sewing transforms labor skill requirements from artisanal craftsmanship to technical proficiency in machine operation and troubleshooting.

Scalability and Flexibility in Production

Manual sewing offers greater flexibility in production, allowing for intricate designs, custom adjustments, and small batch variations that automated sewing machines may struggle to replicate. Automated sewing excels in scalability, enabling high-volume production with consistent quality and faster turnaround times, making it ideal for large manufacturing runs. Balancing manual and automated sewing processes enhances overall production efficiency by combining personalized craftsmanship with mass production capabilities.

Impact on Product Innovation and Design

Manual sewing allows greater flexibility and precision in creating intricate designs and customized details, fostering unique product innovation through hands-on craftsmanship. Automated sewing enables high-speed production and consistent quality, which supports scalable innovation by quickly bringing complex design concepts to market. The synergy between manual techniques and automated technology drives progressive advancements in fashion and textile design.

Sustainability and Environmental Considerations

Manual sewing significantly reduces energy consumption and waste, using minimal machinery and often repurposing materials, which aligns with sustainable fashion practices. Automated sewing machines, while increasing production efficiency, rely on electricity and generate more textile waste due to faster cutting and sewing processes. Choosing manual sewing supports eco-friendly garment production by lowering carbon emissions and promoting resource conservation in the textile industry.

Choosing the Right Sewing Method for Your Business

Selecting the optimal sewing method hinges on factors such as production volume, fabric type, and budget constraints. Manual sewing offers unmatched precision and customization for intricate designs and small batches, while automated sewing increases efficiency and consistency for large-scale manufacturing. Balancing labor costs with desired product quality ensures the best choice between manual and automated sewing for your business growth.

Manual Sewing vs Automated Sewing Infographic

bizdif.com

bizdif.com