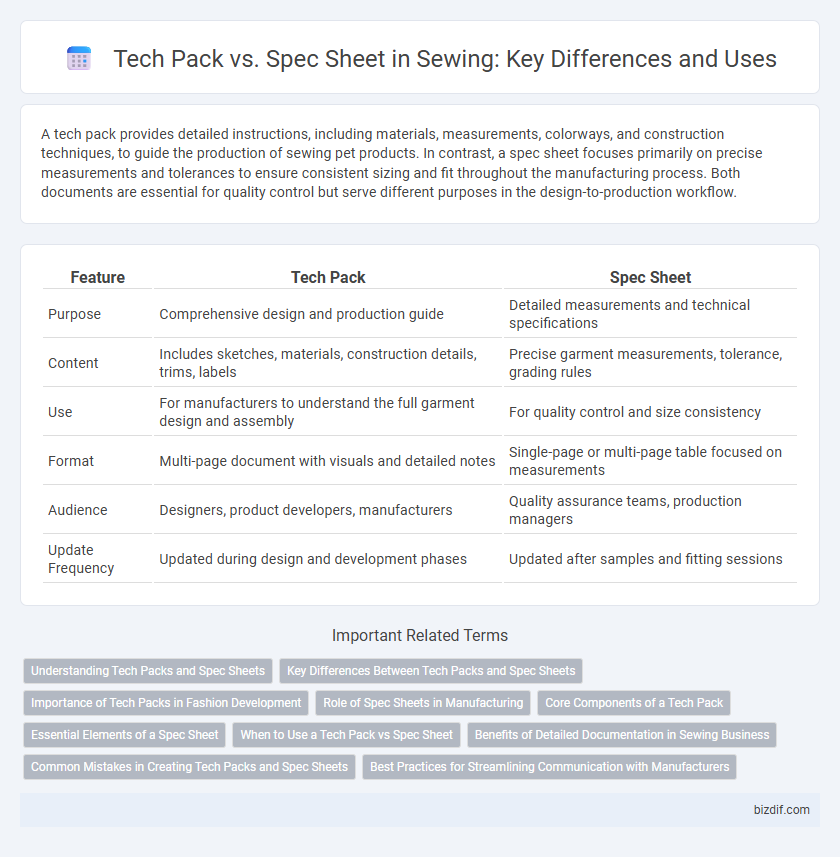

A tech pack provides detailed instructions, including materials, measurements, colorways, and construction techniques, to guide the production of sewing pet products. In contrast, a spec sheet focuses primarily on precise measurements and tolerances to ensure consistent sizing and fit throughout the manufacturing process. Both documents are essential for quality control but serve different purposes in the design-to-production workflow.

Table of Comparison

| Feature | Tech Pack | Spec Sheet |

|---|---|---|

| Purpose | Comprehensive design and production guide | Detailed measurements and technical specifications |

| Content | Includes sketches, materials, construction details, trims, labels | Precise garment measurements, tolerance, grading rules |

| Use | For manufacturers to understand the full garment design and assembly | For quality control and size consistency |

| Format | Multi-page document with visuals and detailed notes | Single-page or multi-page table focused on measurements |

| Audience | Designers, product developers, manufacturers | Quality assurance teams, production managers |

| Update Frequency | Updated during design and development phases | Updated after samples and fitting sessions |

Understanding Tech Packs and Spec Sheets

Tech packs and spec sheets are essential documents in sewing and garment production, detailing design specifications, materials, measurements, and construction instructions to ensure accuracy and consistency. A tech pack provides a comprehensive overview, including sketches, fabric details, trim, colorways, and production notes, serving as a blueprint for manufacturers. Spec sheets focus more specifically on precise measurements and tolerances, critical for quality control and fit verification in the manufacturing process.

Key Differences Between Tech Packs and Spec Sheets

Tech packs provide comprehensive designs including technical drawings, materials, trims, construction details, and packaging instructions essential for product development. Spec sheets focus on precise measurements, tolerances, and quality standards to ensure accurate sizing and fit throughout production. Tech packs serve as a full blueprint for manufacturing, while spec sheets concentrate on the critical quantitative data for quality control.

Importance of Tech Packs in Fashion Development

Tech packs are essential in fashion development as they provide detailed instructions, measurements, materials, and construction guidelines, ensuring consistent production quality. Unlike spec sheets that primarily focus on measurements and fit, tech packs include comprehensive technical data that bridges the communication gap between designers and manufacturers. Accurate tech packs reduce errors, streamline production timelines, and facilitate efficient sourcing, making them crucial for successful garment development.

Role of Spec Sheets in Manufacturing

Spec sheets play a crucial role in manufacturing by providing detailed measurements, material specifications, construction instructions, and quality standards necessary to produce garments accurately and consistently. Unlike tech packs that offer comprehensive design and development information, spec sheets focus specifically on technical details that ensure each product meets exact manufacturing requirements and tolerances. This precision reduces errors, streamlines production, and enhances communication between designers, factories, and quality control teams.

Core Components of a Tech Pack

The core components of a tech pack include detailed flat sketches, precise measurements, fabric and trim specifications, construction details, and labeling instructions, all crucial for consistent garment production. A spec sheet, on the other hand, primarily focuses on measurements and tolerances without the comprehensive design and material information found in a tech pack. These components ensure clear communication between designers and manufacturers, reducing errors and streamlining the production process.

Essential Elements of a Spec Sheet

A spec sheet in sewing includes detailed measurements, fabric types, color codes, stitch types, and trim specifications, providing clear production guidelines. It outlines tolerances, construction details, and labeling instructions that are crucial for quality control and consistency. This document ensures manufacturers understand exact requirements, reducing errors and streamlining the garment production process.

When to Use a Tech Pack vs Spec Sheet

Tech packs are essential during the initial design and development phases, providing detailed specifications such as measurements, materials, and construction details to guide manufacturers accurately. Spec sheets are more appropriate in the production stage, summarizing critical dimensions and quality standards to ensure consistent manufacturing and quality control. Choosing between a tech pack and a spec sheet depends on the project phase and the level of detail required for communication with suppliers and manufacturers.

Benefits of Detailed Documentation in Sewing Business

Detailed documentation, such as tech packs and spec sheets, streamlines communication between designers and manufacturers, ensuring precise production and reducing errors. This clarity improves product consistency and quality by providing exact measurements, materials, and construction details. Efficient documentation minimizes costly revisions and accelerates time-to-market, boosting overall profitability in the sewing business.

Common Mistakes in Creating Tech Packs and Spec Sheets

Common mistakes in creating tech packs and spec sheets include inconsistent measurements, unclear labeling, and missing detailed construction notes that compromise garment accuracy. Overlooking fabric and trim specifications or failing to standardize formats leads to miscommunication between designers and manufacturers. Ensuring precise technical details and comprehensive visuals is critical to avoid costly production errors in sewing projects.

Best Practices for Streamlining Communication with Manufacturers

Tech packs provide comprehensive details including materials, measurements, construction methods, and artwork to ensure precise garment production. Spec sheets focus specifically on measurements and fit standards, serving as a measurement guideline for quality control. Combining detailed tech packs with accurate spec sheets streamlines communication with manufacturers, reducing errors and accelerating production timelines.

Tech Pack vs Spec Sheet Infographic

bizdif.com

bizdif.com