Buttonhole stitching creates a neat, reinforcing edge around buttonholes to prevent fabric fraying and ensure durability in sewn garments. Bar tack stitching uses tightly packed stitches to strengthen high-stress areas like pocket openings or belt loops, adding extra reinforcement without decorative detailing. Both techniques improve garment longevity but serve different purposes depending on the functional needs of the sewing project.

Table of Comparison

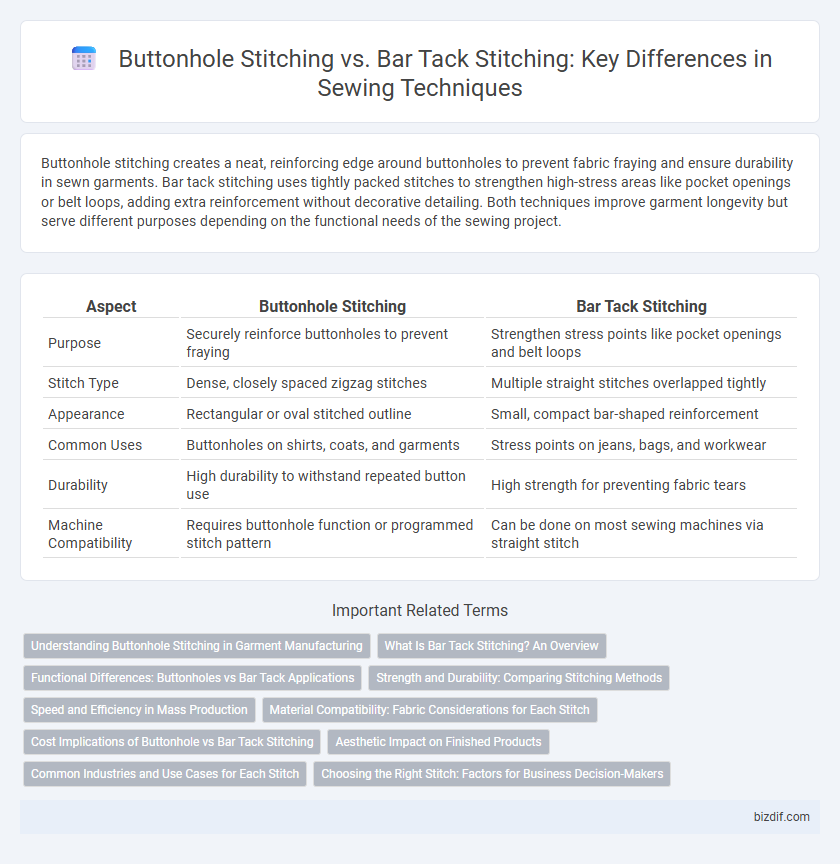

| Aspect | Buttonhole Stitching | Bar Tack Stitching |

|---|---|---|

| Purpose | Securely reinforce buttonholes to prevent fraying | Strengthen stress points like pocket openings and belt loops |

| Stitch Type | Dense, closely spaced zigzag stitches | Multiple straight stitches overlapped tightly |

| Appearance | Rectangular or oval stitched outline | Small, compact bar-shaped reinforcement |

| Common Uses | Buttonholes on shirts, coats, and garments | Stress points on jeans, bags, and workwear |

| Durability | High durability to withstand repeated button use | High strength for preventing fabric tears |

| Machine Compatibility | Requires buttonhole function or programmed stitch pattern | Can be done on most sewing machines via straight stitch |

Understanding Buttonhole Stitching in Garment Manufacturing

Buttonhole stitching in garment manufacturing creates reinforced openings for buttons, using dense, closely spaced stitches that prevent fabric fraying and ensure durability. This technique typically involves a satin stitch or machine-made buttonhole, offering precise, clean edges essential for professional garment finishes. Compared to bar tack stitching, which secures areas of high stress with short, dense stitches, buttonhole stitching combines functionality and aesthetic appeal crucial for fastening systems in apparel.

What Is Bar Tack Stitching? An Overview

Bar tack stitching is a series of closely placed zigzag stitches used to reinforce areas subject to stress or wear, such as pocket openings or belt loops. This type of stitch provides extra durability and prevents fabric from tearing or fraying under tension. Unlike buttonhole stitching, which surrounds buttonholes with a neat, finished edge, bar tack stitching serves as a strong reinforcement technique without forming a complete loop.

Functional Differences: Buttonholes vs Bar Tack Applications

Buttonhole stitching creates a durable opening in fabric designed specifically for fastening buttons, providing both functionality and reinforced edges to prevent fraying. Bar tack stitching, on the other hand, is used to reinforce stress points such as pocket openings or belt loops, offering concentrated strength without creating an opening. Understanding these distinct applications helps optimize garment durability and functionality by applying the correct stitch type based on the specific structural need.

Strength and Durability: Comparing Stitching Methods

Buttonhole stitching offers enhanced strength and durability by closely wrapping thread around the edges, preventing fabric fraying and ensuring long-lasting wear. Bar tack stitching provides concentrated reinforcement at stress points, ideal for securing areas subjected to frequent tension or strain. Choosing between these methods depends on the garment's functional requirements, with buttonhole stitching excelling in edge stability and bar tack stitching maximizing localized durability.

Speed and Efficiency in Mass Production

Buttonhole stitching offers a consistent, clean finish but typically requires more time per garment due to its detailed construction, making it less efficient for high-speed mass production. Bar tack stitching, known for its rapid execution and strong reinforcement, significantly enhances production speed by minimizing machine downtime and allowing faster garment throughput. Factories focused on large-scale output often prefer bar tack stitching to balance durability with maximum efficiency on production lines.

Material Compatibility: Fabric Considerations for Each Stitch

Buttonhole stitching is ideal for medium to heavyweight fabrics such as denim, canvas, and wool, providing a secure, neat finish that prevents fabric fraying around buttonholes. Bar tack stitching excels on lightweight or stretch fabrics like cotton, silk, and knits, reinforcing stress points without adding bulk or compromising fabric elasticity. Choosing the appropriate stitch based on fabric type enhances garment durability and maintains fabric integrity during wear.

Cost Implications of Buttonhole vs Bar Tack Stitching

Buttonhole stitching generally incurs higher production costs due to its intricate design, extended machine time, and frequent need for specialized sewing equipment, whereas bar tack stitching is more cost-efficient with its quicker application and minimal thread usage. The increased durability and decorative appeal of buttonhole stitching may justify its expense for premium garments, but bar tack stitching remains preferred in budget-conscious manufacturing for reinforcing stress points economically. Factoring in labor intensity and material consumption, manufacturers balance these cost implications against garment quality and market positioning when choosing between buttonhole and bar tack stitching methods.

Aesthetic Impact on Finished Products

Buttonhole stitching creates a polished, refined appearance with neat, evenly spaced stitches that enhance garment elegance and durability. Bar tack stitching produces a strong, utilitarian look, often highlighting reinforcement areas with visible, dense stitching that can complement casual or workwear aesthetics. The choice between these techniques significantly influences the visual appeal and perceived quality of the finished product.

Common Industries and Use Cases for Each Stitch

Buttonhole stitching is extensively used in the fashion and apparel industry to secure buttonholes on shirts, jackets, and coats, providing durability and aesthetic finish. Bar tack stitching is prevalent in workwear and denim manufacturing, reinforcing stress points like pocket openings and belt loops to prevent fabric tearing. Both stitches enhance garment strength but serve distinct functional purposes based on industry-specific requirements.

Choosing the Right Stitch: Factors for Business Decision-Makers

Buttonhole stitching provides a clean, reinforced opening ideal for functional and decorative purposes, while bar tack stitching offers concentrated strength at stress points such as pocket openings or belt loops. Business decision-makers should consider fabric type, garment end-use, and production costs when choosing between buttonhole and bar tack stitching to ensure durability and customer satisfaction. Optimizing stitch selection enhances product quality, reduces returns, and aligns with brand reputation for consistency and reliability in apparel manufacturing.

Buttonhole stitching vs Bar tack stitching Infographic

bizdif.com

bizdif.com