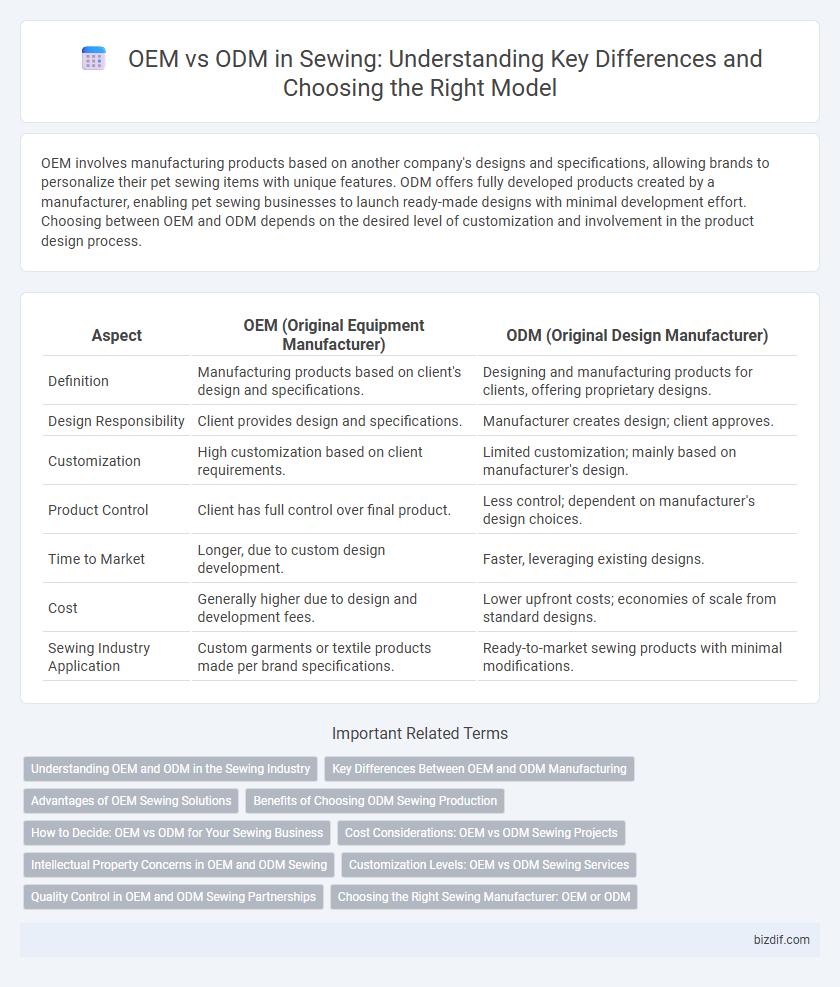

OEM involves manufacturing products based on another company's designs and specifications, allowing brands to personalize their pet sewing items with unique features. ODM offers fully developed products created by a manufacturer, enabling pet sewing businesses to launch ready-made designs with minimal development effort. Choosing between OEM and ODM depends on the desired level of customization and involvement in the product design process.

Table of Comparison

| Aspect | OEM (Original Equipment Manufacturer) | ODM (Original Design Manufacturer) |

|---|---|---|

| Definition | Manufacturing products based on client's design and specifications. | Designing and manufacturing products for clients, offering proprietary designs. |

| Design Responsibility | Client provides design and specifications. | Manufacturer creates design; client approves. |

| Customization | High customization based on client requirements. | Limited customization; mainly based on manufacturer's design. |

| Product Control | Client has full control over final product. | Less control; dependent on manufacturer's design choices. |

| Time to Market | Longer, due to custom design development. | Faster, leveraging existing designs. |

| Cost | Generally higher due to design and development fees. | Lower upfront costs; economies of scale from standard designs. |

| Sewing Industry Application | Custom garments or textile products made per brand specifications. | Ready-to-market sewing products with minimal modifications. |

Understanding OEM and ODM in the Sewing Industry

OEM (Original Equipment Manufacturer) in the sewing industry involves producing garments or textiles based on designs and specifications provided by a client, allowing brands to outsource manufacturing while maintaining control over product design. ODM (Original Design Manufacturer) offers a more comprehensive service by designing, developing, and manufacturing products, enabling clients to market original creations without investing in design resources. Understanding the distinctions between OEM and ODM helps businesses optimize production strategies, streamline supply chains, and bring custom or unique sewing products to market efficiently.

Key Differences Between OEM and ODM Manufacturing

OEM manufacturing involves producing products based on the buyer's design specifications, allowing companies to maintain control over product design while outsourcing production. ODM manufacturing provides complete design and manufacturing services, enabling brands to bring products to market faster without investing in product development. Key differences include the level of design involvement, with OEMs focusing on manufacturing and ODMs offering end-to-end solutions, impacting flexibility, cost, and time-to-market in the sewing industry.

Advantages of OEM Sewing Solutions

OEM sewing solutions provide manufacturers with high customization options, enabling tailored garment production that meets specific brand requirements. These solutions offer cost efficiency by leveraging existing production capabilities and reducing research and development expenses. OEM partnerships ensure consistent product quality and faster time-to-market, essential for competitive apparel businesses.

Benefits of Choosing ODM Sewing Production

Choosing ODM sewing production streamlines the manufacturing process by providing ready-made designs with customizable options that reduce development time and costs. This approach leverages the expertise of experienced design teams to ensure high-quality, trend-aligned garments that meet market demands efficiently. ODM sewing offers scalability and faster time-to-market, ideal for brands looking to innovate without extensive in-house design resources.

How to Decide: OEM vs ODM for Your Sewing Business

Choosing between OEM and ODM for your sewing business hinges on control and customization needs, with OEM offering you full control over designs while ODM provides ready-made products for faster market entry. Evaluate your capacity for design development and the importance of brand identity before deciding. Consider factors like production volume, design expertise, and time-to-market to determine the most efficient manufacturing approach.

Cost Considerations: OEM vs ODM Sewing Projects

OEM sewing projects typically involve lower upfront costs as they utilize existing designs and specifications, reducing the need for research and development expenses. ODM sewing projects often incur higher initial costs due to custom design creation and proprietary development, but they may offer long-term savings through unique product differentiation. Cost considerations must balance between short-term manufacturing efficiencies of OEM and the strategic value added by ODM innovation in sewing production.

Intellectual Property Concerns in OEM and ODM Sewing

OEM sewing involves manufacturing products based on client designs, raising intellectual property concerns primarily around design confidentiality and unauthorized replication. ODM sewing includes both design and production, heightening risks related to ownership of original designs and potential misuse of proprietary techniques. Clear contracts and robust IP protections are essential to safeguard the rights of both parties in OEM and ODM sewing agreements.

Customization Levels: OEM vs ODM Sewing Services

OEM sewing services focus on manufacturing products based on a buyer's provided designs and specifications, offering limited customization beyond material or minor design tweaks. ODM sewing services provide higher customization levels, including product design, development, and original creation tailored to client needs, enabling complete control over style, fabric, and features. Choosing between OEM and ODM depends on the desired level of involvement in the design process and the scope of customization required for the final sewn product.

Quality Control in OEM and ODM Sewing Partnerships

Quality control in OEM sewing partnerships emphasizes adherence to client specifications and maintaining consistent production standards through rigorous inspection processes. ODM sewing collaborations prioritize innovative design integration with quality checks at each manufacturing stage to ensure product durability and brand integrity. Both OEM and ODM models implement comprehensive quality assurance protocols to minimize defects and optimize garment performance.

Choosing the Right Sewing Manufacturer: OEM or ODM

Choosing the right sewing manufacturer hinges on whether you need OEM (Original Equipment Manufacturer) or ODM (Original Design Manufacturer) services, depending on your product development stage. OEM manufacturers specialize in producing customized sewing products based on your detailed designs, ideal for brands with established specifications. ODM providers handle both design and manufacturing, offering turnkey sewing solutions and innovative garment design, which suits startups or businesses seeking unique, ready-to-market apparel.

OEM vs ODM Infographic

bizdif.com

bizdif.com