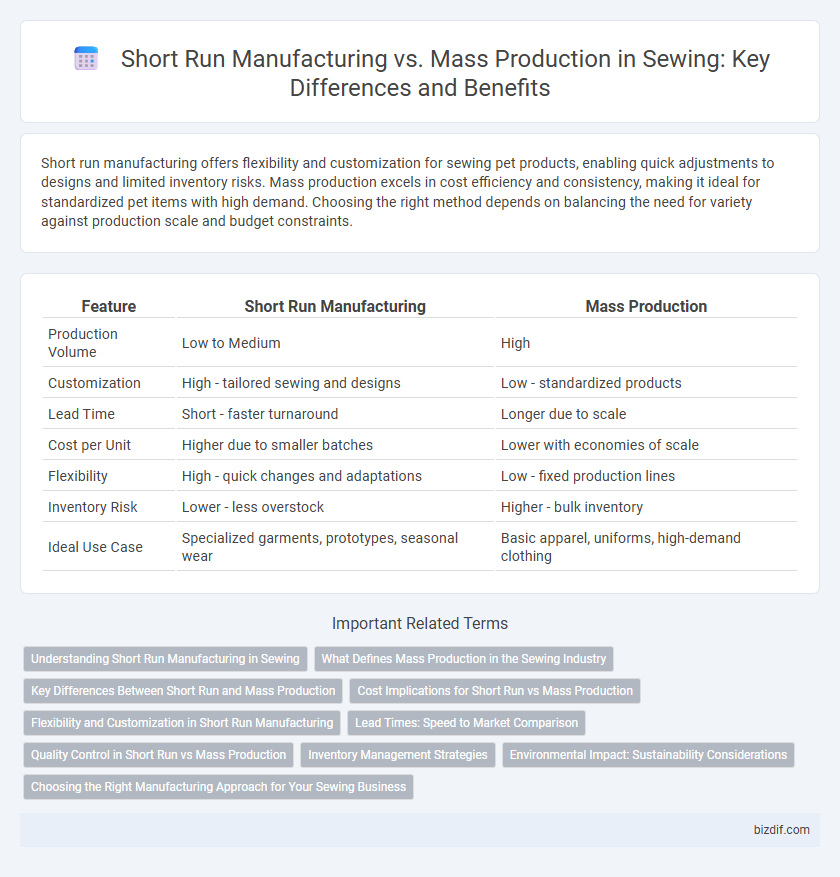

Short run manufacturing offers flexibility and customization for sewing pet products, enabling quick adjustments to designs and limited inventory risks. Mass production excels in cost efficiency and consistency, making it ideal for standardized pet items with high demand. Choosing the right method depends on balancing the need for variety against production scale and budget constraints.

Table of Comparison

| Feature | Short Run Manufacturing | Mass Production |

|---|---|---|

| Production Volume | Low to Medium | High |

| Customization | High - tailored sewing and designs | Low - standardized products |

| Lead Time | Short - faster turnaround | Longer due to scale |

| Cost per Unit | Higher due to smaller batches | Lower with economies of scale |

| Flexibility | High - quick changes and adaptations | Low - fixed production lines |

| Inventory Risk | Lower - less overstock | Higher - bulk inventory |

| Ideal Use Case | Specialized garments, prototypes, seasonal wear | Basic apparel, uniforms, high-demand clothing |

Understanding Short Run Manufacturing in Sewing

Short run manufacturing in sewing involves producing limited quantities of garments tailored to specific client needs, allowing for greater customization and faster turnaround times. This approach reduces inventory costs, minimizes waste, and offers flexibility to adjust designs or respond to market trends quickly. It contrasts with mass production by focusing on quality and adaptability rather than large-scale output and standardized products.

What Defines Mass Production in the Sewing Industry

Mass production in the sewing industry is characterized by large-scale manufacturing processes designed to produce high volumes of garment units using standardized patterns and automated machinery. This approach emphasizes efficiency, consistency, and cost reduction through assembly line techniques and repetitive tasks. Factories implementing mass production typically maintain strict quality control measures and rely on specialized labor to maximize output and meet extensive market demands.

Key Differences Between Short Run and Mass Production

Short run manufacturing in sewing emphasizes flexibility and customization, producing limited quantities tailored to specific needs, while mass production focuses on high-volume output with standardized designs to maximize efficiency. Short run processes typically involve quicker setup times and lower inventory risks, contrasting with mass production's capital-intensive equipment and longer production cycles. The key differences lie in production scale, turnaround time, and adaptability to design changes, making short run ideal for niche markets and mass production suited for large-scale distribution.

Cost Implications for Short Run vs Mass Production

Short run manufacturing in sewing typically incurs higher per-unit costs due to setup times, limited economies of scale, and frequent machine adjustments. Mass production lowers costs significantly by optimizing workflow, reducing labor expenses per unit, and purchasing materials in bulk. However, short run manufacturing offers flexibility and reduced inventory risks, beneficial for custom or limited edition garments despite the increased cost per piece.

Flexibility and Customization in Short Run Manufacturing

Short run manufacturing in sewing offers unparalleled flexibility, enabling quick adjustments to designs and production volumes without significant downtime or cost increases. This method supports high levels of customization, allowing manufacturers to cater to niche markets and unique client specifications with ease. Unlike mass production, which prioritizes uniformity and scale, short run manufacturing excels in adaptability, making it ideal for fashion trends that demand rapid response and personalized garments.

Lead Times: Speed to Market Comparison

Short run manufacturing typically offers significantly shorter lead times, enabling faster turnaround from design to finished garment, often within days or weeks. Mass production involves longer lead times due to large volume orders, complex setup processes, and extensive quality checks, usually spanning several weeks to months. Faster speed to market with short runs allows brands to respond quickly to trends and reduce inventory risks, while mass production favors cost efficiency for high-volume demand.

Quality Control in Short Run vs Mass Production

Short run manufacturing in sewing emphasizes rigorous quality control processes with frequent inspections to ensure each batch meets specific standards, reducing defects and waste. Mass production relies on streamlined quality control systems optimized for speed and volume, often implementing statistical process control to monitor consistent output across large quantities. The precision of quality control in short runs allows for greater customization and adaptability, whereas mass production prioritizes consistency and efficiency over individualized scrutiny.

Inventory Management Strategies

Short run manufacturing in sewing allows for more flexible inventory management by producing smaller batches tailored to immediate demand, reducing storage costs and minimizing excess stock. Mass production relies on forecasting to build large inventory quantities, which can lead to overstocking or stockouts if demand shifts unexpectedly. Implementing just-in-time inventory strategies in short run manufacturing optimizes material usage and accelerates turnover, while mass production benefits from economies of scale but requires robust demand prediction models to manage inventory effectively.

Environmental Impact: Sustainability Considerations

Short run manufacturing in sewing significantly reduces fabric waste and energy consumption due to smaller batch sizes, promoting sustainable practices. Mass production often leads to excess inventory and higher resource use, increasing environmental strain through water pollution and carbon emissions. Choosing short run methods supports eco-friendly supply chains by minimizing overproduction and encouraging the use of sustainable materials.

Choosing the Right Manufacturing Approach for Your Sewing Business

Short run manufacturing offers sewing businesses greater flexibility, lower initial costs, and the ability to quickly respond to market trends or customer demands compared to mass production. Mass production, while ideal for large-scale orders, requires significant investment in machinery and materials, making it less suitable for smaller or customized sewing projects. Evaluating order volume, customization needs, and budget constraints is essential for selecting the optimal manufacturing approach in the sewing industry.

Short Run Manufacturing vs Mass Production Infographic

bizdif.com

bizdif.com