Seamless garments offer enhanced comfort and flexibility due to their construction without stitches, reducing irritation on sensitive pet skin and allowing for greater freedom of movement. Cut-sew garments, on the other hand, provide more design versatility with distinct panel assembly but may result in visible seams that can cause discomfort or chafing for active pets. Choosing between seamless and cut-sew options depends on prioritizing either maximum comfort or intricate design features for pet clothing.

Table of Comparison

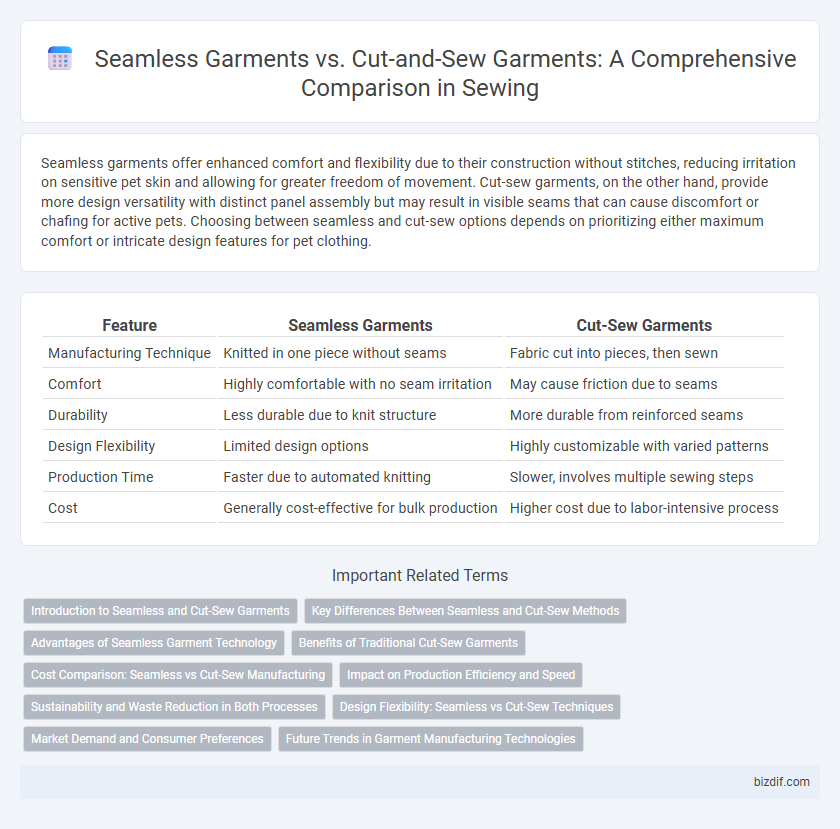

| Feature | Seamless Garments | Cut-Sew Garments |

|---|---|---|

| Manufacturing Technique | Knitted in one piece without seams | Fabric cut into pieces, then sewn |

| Comfort | Highly comfortable with no seam irritation | May cause friction due to seams |

| Durability | Less durable due to knit structure | More durable from reinforced seams |

| Design Flexibility | Limited design options | Highly customizable with varied patterns |

| Production Time | Faster due to automated knitting | Slower, involves multiple sewing steps |

| Cost | Generally cost-effective for bulk production | Higher cost due to labor-intensive process |

Introduction to Seamless and Cut-Sew Garments

Seamless garments are created using knitting machines that form the fabric in a tubular shape without any side seams, offering enhanced comfort and flexibility. Cut-sew garments involve cutting fabric pieces from flat rolls and stitching them together, allowing for a wide range of designs and precise fitting. These fundamental differences influence manufacturing efficiency, garment structure, and consumer experience in the apparel industry.

Key Differences Between Seamless and Cut-Sew Methods

Seamless garments are produced using advanced knitting technology that eliminates stitches, resulting in smooth, form-fitting apparel ideal for activewear and lingerie. Cut-sew garments involve cutting fabric pieces and sewing them together, allowing for more complex designs, varied materials, and greater customization. Seamless methods enhance comfort and reduce production time, while cut-sew techniques offer versatility and detailed construction options.

Advantages of Seamless Garment Technology

Seamless garment technology offers superior comfort by eliminating bulky seams that cause irritation and restrict movement, making it ideal for activewear. This method reduces fabric waste through advanced knitting techniques, promoting sustainability and cost-efficiency in production. Enhanced durability and a sleek, form-fitting design are additional advantages, positioning seamless garments as a cutting-edge solution in modern apparel manufacturing.

Benefits of Traditional Cut-Sew Garments

Traditional cut-sew garments offer superior customization and precise fit adjustments due to their segmented construction, allowing for tailored designs that accommodate diverse body shapes. The segmented sewing process enhances fabric variety and texture combinations, enabling complex patterns and structural details unattainable in seamless garments. Production methods for cut-sew garments also streamline alterations and repairs, extending garment lifespan and enhancing sustainability in fashion manufacturing.

Cost Comparison: Seamless vs Cut-Sew Manufacturing

Seamless garment manufacturing significantly reduces labor costs by eliminating stitching processes, resulting in lower production expenses compared to cut-sew methods. Cut-sew garments involve multiple steps including pattern cutting, sewing, and finishing, which increase labor and material waste costs. Despite higher upfront investment in seamless knitting technology, overall cost efficiency improves with large production volumes, making seamless garments more economical in mass manufacturing.

Impact on Production Efficiency and Speed

Seamless garments significantly enhance production efficiency by eliminating multiple sewing steps, reducing labor time, and minimizing fabric waste compared to cut-sew garments. The continuous knitting technology in seamless manufacturing accelerates production speed, enabling faster turnaround times and scalability for mass production. In contrast, cut-sew garments require intricate pattern cutting and stitching processes that slow down manufacturing and increase the potential for errors.

Sustainability and Waste Reduction in Both Processes

Seamless garments utilize advanced knitting technology that eliminates fabric cutting, significantly reducing textile waste compared to traditional cut-sew garments, which generate substantial offcuts during the pattern cutting phase. This innovative process lowers environmental impact by minimizing material use and energy consumption while enabling more efficient production cycles. Cut-sew methods, despite higher waste, allow for versatile designs and repairs, but sustainable practices like zero-waste pattern making and recycling are crucial to mitigating their environmental footprint.

Design Flexibility: Seamless vs Cut-Sew Techniques

Seamless garments offer enhanced design flexibility by enabling continuous fabric construction without interruption, allowing for smoother fits and complex shapes that reduce material waste. Cut-sew techniques provide customization through pattern cutting and stitching multiple fabric pieces, supporting diverse styles, textures, and color combinations but often result in visible seams. Designers choose seamless methods for ergonomic, streamlined apparel, while cut-sew remains preferred for intricate, multi-fabric designs demanding precise detailing.

Market Demand and Consumer Preferences

Seamless garments experience rising market demand due to their superior comfort, fit, and durability, appealing to consumers seeking innovative activewear and athleisure. Cut-sew garments maintain strong preference because of their versatility, customization options, and cost-efficiency, making them dominant in casual and formal wear. Consumer preference trends indicate a growing shift towards seamless technology in performance apparel, while traditional cut-sew remains preferred in mainstream fashion sectors.

Future Trends in Garment Manufacturing Technologies

Advancements in 3D knitting and automated robotic stitching are driving a shift from traditional cut-sew garments towards seamless garment production, significantly reducing fabric waste and improving fit precision. Innovations in seamless knitting machines enable on-demand manufacturing with minimal labor input, promoting sustainability and customization in apparel. The integration of AI and IoT technologies further enhances real-time quality control and supply chain efficiency, positioning seamless garment technology as the future standard in fashion manufacturing.

Seamless Garments vs Cut-Sew Garments Infographic

bizdif.com

bizdif.com