Single needle sewing machines provide precise, straight stitches ideal for detailed pet garment construction, offering strong seams and excellent control over fabric placement. Overlock machines excel in finishing and trimming fabric edges simultaneously, creating professional-looking hems that prevent fraying and add durability to pet accessories. Choosing between single needle and overlock depends on the project's needs, with single needle focusing on structure and overlock ensuring clean, stretchy seams for comfort and wear.

Table of Comparison

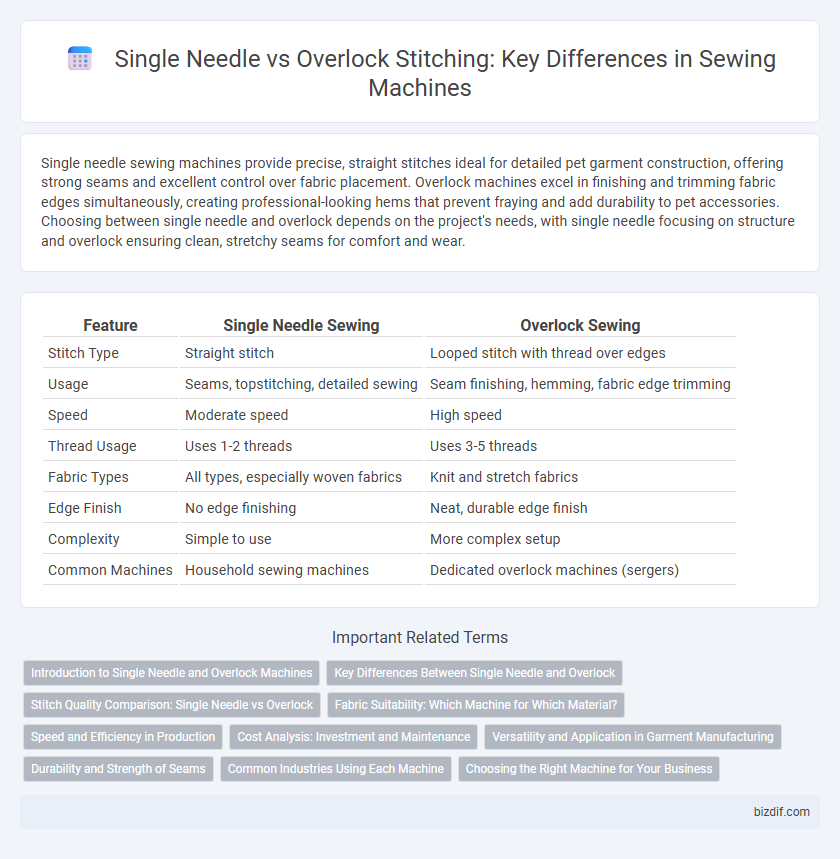

| Feature | Single Needle Sewing | Overlock Sewing |

|---|---|---|

| Stitch Type | Straight stitch | Looped stitch with thread over edges |

| Usage | Seams, topstitching, detailed sewing | Seam finishing, hemming, fabric edge trimming |

| Speed | Moderate speed | High speed |

| Thread Usage | Uses 1-2 threads | Uses 3-5 threads |

| Fabric Types | All types, especially woven fabrics | Knit and stretch fabrics |

| Edge Finish | No edge finishing | Neat, durable edge finish |

| Complexity | Simple to use | More complex setup |

| Common Machines | Household sewing machines | Dedicated overlock machines (sergers) |

Introduction to Single Needle and Overlock Machines

Single needle sewing machines use one needle to create straight, durable stitches ideal for detailed garment construction and precise stitching tasks. Overlock machines, also known as sergers, trim fabric edges while simultaneously sewing and finishing seams with multiple threads, preventing fraying and ensuring professional-quality edges. Choosing between single needle and overlock machines depends on the specific sewing project requirements, such as stitch type, fabric finish, and production speed.

Key Differences Between Single Needle and Overlock

Single needle machines create straight, precise stitches ideal for topstitching and detailed sewing projects, while overlock machines specialize in simultaneously trimming fabric edges and sewing over them to prevent fraying, producing clean seams. Single needle machines use one needle and are suitable for heavier fabrics, whereas overlock machines employ multiple threads and loopers for stretchable, secure stitches on knit or woven materials. The key difference lies in function: single needle machines offer versatility for various stitches, while overlock machines focus on speed and seam finishing.

Stitch Quality Comparison: Single Needle vs Overlock

Single needle machines produce straight, precise stitches ideal for detailed sewing, offering strong seam integrity and minimal fabric distortion. Overlock machines excel in stitch versatility, simultaneously trimming fabric edges while creating durable, stretchable seams perfect for knitwear and high-stress applications. Comparing stitch quality, single needle provides clean, fine stitch lines, whereas overlock delivers reinforced edges with efficient seam finishing, influencing project choice based on fabric type and desired seam durability.

Fabric Suitability: Which Machine for Which Material?

Single needle sewing machines excel in stitching woven fabrics like cotton, linen, and denim, offering precise, strong seams perfect for structured garments. Overlock machines are ideal for knit fabrics such as jersey or spandex, providing stretchable seams and professional edge finishes that prevent fraying. Selecting the right machine based on fabric type ensures durability and optimal garment performance.

Speed and Efficiency in Production

Single needle machines offer precision but operate at slower speeds, making them suitable for detailed stitching and tailored garments. Overlock machines excel in speed, efficiently trimming and finishing seams simultaneously, which significantly boosts production rates in mass manufacturing. Choosing overlock technology enhances workflow by reducing cycle times and minimizing fabric handling during high-volume sewing operations.

Cost Analysis: Investment and Maintenance

Single needle sewing machines typically demand a lower initial investment, with prices ranging from $100 to $500, and their maintenance costs are moderate, primarily involving needle replacement and occasional servicing. Overlock machines, however, require a higher upfront cost often between $300 and $1,000 due to their specialized threading system and multiple blades, and maintenance expenses include blade replacements and more frequent lubrication. Evaluating long-term cost efficiency depends on production volume and fabric types, as overlocks enhance speed and seam durability, potentially offsetting higher maintenance expenses in industrial or large-scale applications.

Versatility and Application in Garment Manufacturing

Single needle machines offer high precision and are ideal for detailed stitching and topstitching in garment manufacturing, making them versatile for various fabric types and designs. Overlock machines excel in finishing seams by trimming and enclosing edges simultaneously, providing durability and preventing fraying, which is crucial for knitwear and stretch fabrics. Combining single needle and overlock machines enhances production efficiency and garment quality, catering to both intricate construction and strong seam finishes.

Durability and Strength of Seams

Single needle sewing creates strong, precise seams with excellent tension control, ideal for durable garments requiring clean lines. Overlock stitching offers reinforced seams by encasing fabric edges, enhancing elasticity and preventing fraying, which is essential for stretch fabrics and high-stress areas. While single needle seams provide superior seam strength for structured pieces, overlock seams excel in durability for garments exposed to frequent wear and movement.

Common Industries Using Each Machine

Single needle machines are widely used in garment manufacturing industries requiring precise stitching, such as tailoring, denim, and formal wear production. Overlock machines dominate in apparel sectors focused on knitwear, activewear, and home textiles, where edge finishing and stretch fabric seams are essential. Both machines are critical in mass production facilities, with single needle machines emphasizing durability and overlocks enhancing seam elasticity and speed.

Choosing the Right Machine for Your Business

Choosing the right sewing machine for your business depends on the type of projects and fabrics you work with most. Single needle machines offer precision and versatility for detailed stitching and garment construction, ideal for tailored clothing and lighter fabrics. Overlock machines excel in seam finishing and edge trimming, providing durability and professional-quality results for knit fabrics and mass production environments.

Single needle vs Overlock Infographic

bizdif.com

bizdif.com