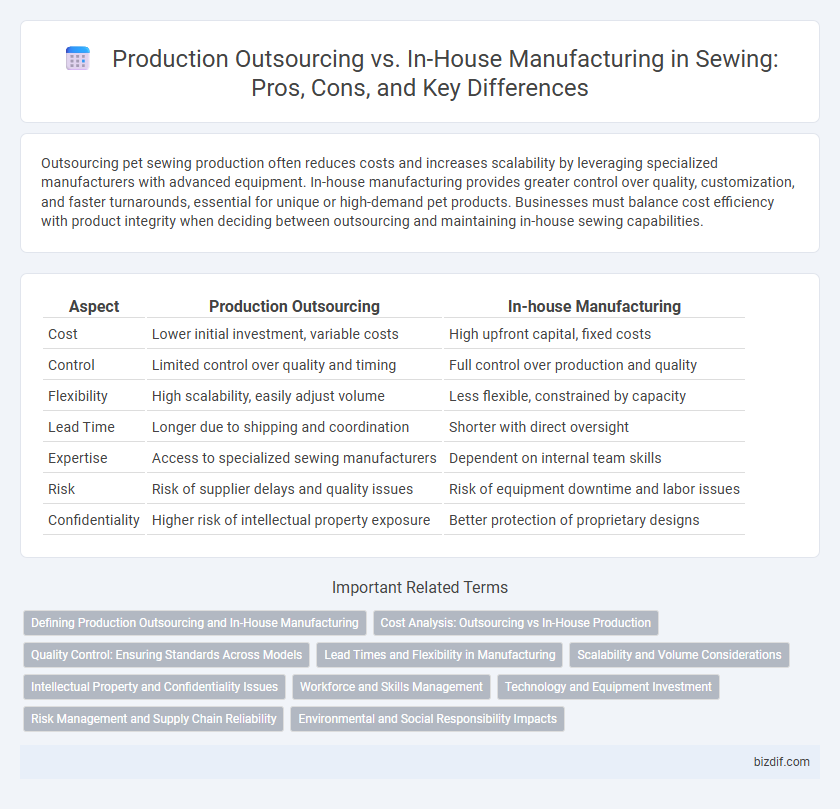

Outsourcing pet sewing production often reduces costs and increases scalability by leveraging specialized manufacturers with advanced equipment. In-house manufacturing provides greater control over quality, customization, and faster turnarounds, essential for unique or high-demand pet products. Businesses must balance cost efficiency with product integrity when deciding between outsourcing and maintaining in-house sewing capabilities.

Table of Comparison

| Aspect | Production Outsourcing | In-house Manufacturing |

|---|---|---|

| Cost | Lower initial investment, variable costs | High upfront capital, fixed costs |

| Control | Limited control over quality and timing | Full control over production and quality |

| Flexibility | High scalability, easily adjust volume | Less flexible, constrained by capacity |

| Lead Time | Longer due to shipping and coordination | Shorter with direct oversight |

| Expertise | Access to specialized sewing manufacturers | Dependent on internal team skills |

| Risk | Risk of supplier delays and quality issues | Risk of equipment downtime and labor issues |

| Confidentiality | Higher risk of intellectual property exposure | Better protection of proprietary designs |

Defining Production Outsourcing and In-House Manufacturing

Production outsourcing in sewing involves contracting external manufacturers to handle garment creation, leveraging specialized facilities and skill sets to reduce costs and increase scalability. In-house manufacturing refers to producing garments within a company's own facilities, allowing for greater control over quality, design modifications, and production timelines. Choosing between these models depends on factors such as budget, production volume, and the need for flexibility in product development.

Cost Analysis: Outsourcing vs In-House Production

Outsourcing sewing production often reduces labor and overhead costs by leveraging lower wages and specialized facilities abroad, while in-house manufacturing incurs higher fixed costs including equipment, staffing, and facility maintenance. Cost analysis must consider variable expenses such as raw materials, quality control, and shipping fees for outsourcing, which can fluctuate significantly. In contrast, in-house production offers greater control over processes and timelines but demands substantial initial capital investment and ongoing operational expenses.

Quality Control: Ensuring Standards Across Models

Production outsourcing in sewing often challenges consistent quality control due to varied standards across different manufacturers, risking discrepancies in fabric handling and stitching precision. In-house manufacturing provides direct oversight, enabling uniform quality checks and immediate correction of defects across all garment models. Leveraging advanced inspection technologies and standardized quality protocols ensures adherence to design specifications and customer expectations.

Lead Times and Flexibility in Manufacturing

Production outsourcing in sewing significantly reduces lead times by leveraging specialized factories with scalable resources and streamlined workflows. In-house manufacturing offers greater flexibility in design changes and quality control, enabling rapid adjustments during production without third-party delays. Balancing lead times and manufacturing flexibility is crucial for apparel brands aiming to respond quickly to market trends while maintaining product standards.

Scalability and Volume Considerations

Outsourcing production in sewing offers greater scalability, enabling manufacturers to handle large volume orders without the need for significant capital investment in machinery or labor. In-house manufacturing provides tighter quality control and faster turnaround for smaller production runs but may struggle to scale efficiently when demand surges. Balancing cost, flexibility, and volume capacity determines the optimal approach for meeting market growth and production deadlines.

Intellectual Property and Confidentiality Issues

Production outsourcing in sewing presents significant risks to intellectual property (IP) protection and confidentiality due to third-party access to proprietary designs and techniques. In-house manufacturing offers enhanced control over trade secrets and reduces potential IP theft, enabling secure handling of sensitive information within the company. Companies prioritizing brand integrity and innovation often prefer in-house production to safeguard confidential patterns, custom fabrics, and exclusive sewing methods.

Workforce and Skills Management

Outsourcing production in sewing allows access to specialized workforce and advanced skills without investing in extensive training, enabling flexibility in scaling operations. In-house manufacturing ensures greater control over skill development and employee expertise, fostering consistent quality and faster adaptation to design changes. Efficient workforce and skills management directly impact production timelines, cost optimization, and product quality in both strategies.

Technology and Equipment Investment

Production outsourcing in sewing allows companies to leverage advanced technology and specialized equipment from external partners, reducing capital expenditure and maintenance costs. In-house manufacturing demands significant investment in state-of-the-art sewing machines, automation technology, and skilled labor training to maintain high-quality production standards. Balancing technology integration and equipment upgrades is crucial for optimizing efficiency and competitiveness in both outsourcing and in-house models.

Risk Management and Supply Chain Reliability

Production outsourcing in sewing offers flexibility but introduces risks such as quality control issues and supply chain disruptions due to dependence on third-party vendors. In-house manufacturing provides greater oversight and reduces vulnerabilities by maintaining direct control over production processes and timelines. Balancing risk management and supply chain reliability requires evaluating cost efficiency against potential delays, quality inconsistencies, and inventory management challenges.

Environmental and Social Responsibility Impacts

Production outsourcing in sewing often leads to reduced environmental control and potential labor rights issues, as external facilities may lack stringent sustainability policies or proper worker protections. In-house manufacturing enables companies to implement rigorous environmental standards, such as waste reduction and energy efficiency, while ensuring fair labor practices and transparent working conditions. Prioritizing local production supports social responsibility by fostering community employment and minimizing carbon emissions associated with global transportation.

Production outsourcing vs In-house manufacturing Infographic

bizdif.com

bizdif.com