Seam finishing is essential in sewing pets' accessories to prevent fabric fraying and enhance durability, while raw edges can lead to unraveling and a less polished look. Techniques like zigzag stitching, serging, or bias binding provide clean, strong seams that withstand wear and washing. Choosing proper seam finishing improves both the safety and longevity of pet garments and beds.

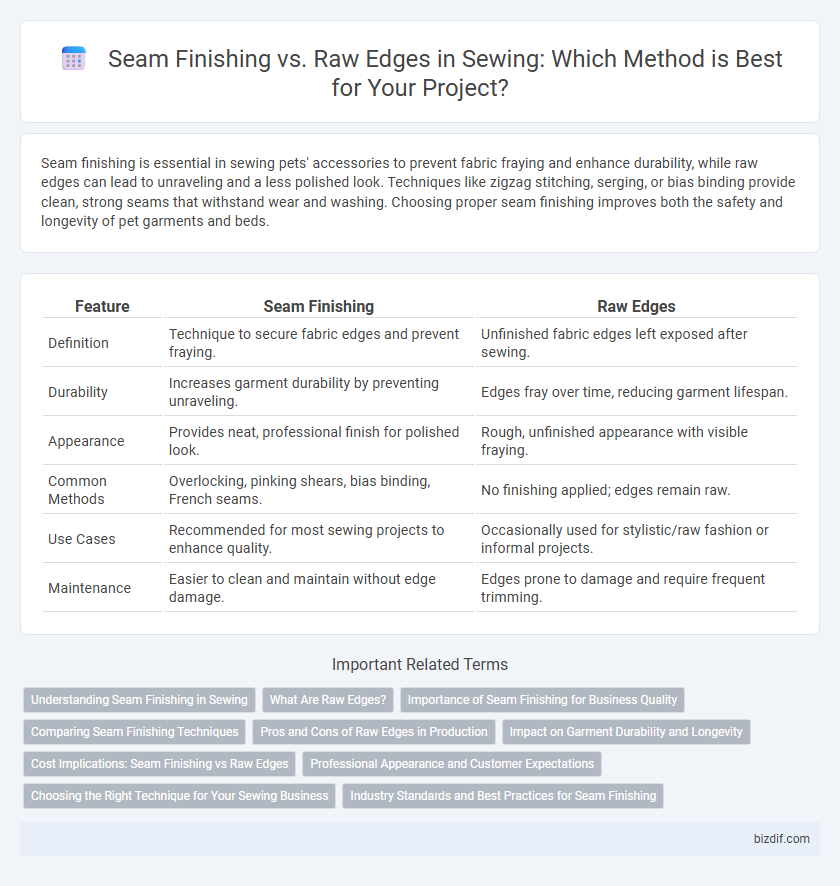

Table of Comparison

| Feature | Seam Finishing | Raw Edges |

|---|---|---|

| Definition | Technique to secure fabric edges and prevent fraying. | Unfinished fabric edges left exposed after sewing. |

| Durability | Increases garment durability by preventing unraveling. | Edges fray over time, reducing garment lifespan. |

| Appearance | Provides neat, professional finish for polished look. | Rough, unfinished appearance with visible fraying. |

| Common Methods | Overlocking, pinking shears, bias binding, French seams. | No finishing applied; edges remain raw. |

| Use Cases | Recommended for most sewing projects to enhance quality. | Occasionally used for stylistic/raw fashion or informal projects. |

| Maintenance | Easier to clean and maintain without edge damage. | Edges prone to damage and require frequent trimming. |

Understanding Seam Finishing in Sewing

Seam finishing is a crucial technique in sewing that prevents fabric edges from fraying, ensuring durability and a polished look. Common seam finishing methods include serging, pinking shears, and binding, each tailored to different fabric types and project needs. Proper seam finishing enhances garment longevity and overall quality by reinforcing seams and maintaining fabric integrity.

What Are Raw Edges?

Raw edges are the unfinished, cut edges of fabric that have not been sewn or treated to prevent fraying. These edges can unravel over time, compromising the durability and appearance of a sewn garment or textile project. Proper seam finishing techniques such as serging, binding, or pinking shears are essential to secure raw edges and maintain fabric integrity.

Importance of Seam Finishing for Business Quality

Seam finishing prevents fabric fraying, ensuring garment durability and enhancing professional appearance, which directly impacts customer satisfaction and brand reputation. Consistent seam finishing in production reduces returns and increases product longevity, driving better business outcomes. High-quality seam finishes also elevate perceived value, allowing for premium pricing in competitive markets.

Comparing Seam Finishing Techniques

Seam finishing techniques such as serging, pinking shears, and binding prevent fabric fraying and ensure garment durability, contrasting with raw edges which are prone to unraveling and a less polished appearance. Serging creates a clean, professional edge using overlock stitches, while pinking shears provide a quick, fray-preventative zigzag cut ideal for lightweight fabrics. Binding encases seams with additional fabric or tape, offering enhanced strength and tailored aesthetics compared to exposed raw edges.

Pros and Cons of Raw Edges in Production

Raw edges in sewing production offer the advantage of faster assembly time and reduced material waste, making them cost-effective for large-scale manufacturing. However, raw edges are prone to fraying, which can compromise garment durability and necessitate additional treatments like binding or serging to maintain quality. The trade-off between speed and finish quality with raw edges requires careful consideration depending on the garment type and production standards.

Impact on Garment Durability and Longevity

Seam finishing techniques such as serging, binding, or pinking prevent fabric fraying, significantly enhancing garment durability and longevity compared to raw edges, which tend to unravel quickly. Proper seam finishing maintains structural integrity, reduces fabric stress during wear and washing, and preserves the garment's aesthetic quality over time. Choosing the right seam finish tailored to fabric type ensures extended lifespan and sustained garment performance.

Cost Implications: Seam Finishing vs Raw Edges

Seam finishing techniques such as serging, binding, or pinking shears add to sewing costs due to additional materials, tools, and labor involved, while raw edges reduce initial expenses but risk fabric fraying and durability issues. Over time, costs associated with repairs or garment replacement can exceed initial savings from leaving seams raw. Investing in proper seam finishing enhances garment longevity and value, offsetting upfront expenditures with long-term savings.

Professional Appearance and Customer Expectations

Seam finishing techniques such as serging, binding, or topstitching create clean, durable edges that enhance the garment's professional appearance and prevent fraying, meeting customer expectations for quality craftsmanship. Raw edges, often found in unfinished or hobbyist sewing projects, tend to fray quickly and can give a garment an unrefined look, which may diminish perceived value. By mastering seam finishing methods, sewists ensure garments withstand wear over time, aligning with industry standards and consumer demands for polished, long-lasting products.

Choosing the Right Technique for Your Sewing Business

Selecting the appropriate seam finishing technique is crucial for ensuring garment durability and customer satisfaction in your sewing business. Techniques such as serging, binding, or pinking shears each provide different levels of edge protection and aesthetic appeal, depending on fabric type and product purpose. Proper seam finishing prevents fabric fraying, enhances garment longevity, and elevates overall product quality, directly impacting brand reputation and sales.

Industry Standards and Best Practices for Seam Finishing

Industry standards for seam finishing prioritize durability, preventing fabric fraying, and ensuring garment longevity, commonly recommending techniques like serging, binding, and pinking shears. Best practices emphasize clean, secure seams tailored to fabric type and garment use, with professional finishes such as bias binding or overlocking considered essential in apparel manufacturing. Raw edges are typically avoided in finished garments except in designs where fraying is stylistically intentional, as they compromise structural integrity and quality perceptions.

Seam Finishing vs Raw Edges Infographic

bizdif.com

bizdif.com